Wepco Plastics President David Parmelee and his leadership team provide a budget and a deadline for each investment decision and then let the rest of the team take on the remaining responsibility. Photo Credit, all images: Wepco Plastics

Every business must make periodic investments to stay competitive. Investments include new equipment, software, workforce and real estate, which can be an exciting and potentially anxiety-provoking process. While appropriate investment can dramatically improve a company’s success, the outcome could be undesirable if you do not follow a thorough process. A robust process is necessary because money and time are in limited supply. Businesses must make sure they spend these restricted resources wisely.

Create a solid process, follow that process and improve it along the way, which alone is a terrific investment for your business.

One Step at a Time

Before you do anything, organize a diverse group of people who consider all the necessary factors to make these crucial investment decisions. Members of this group should represent purchasing, finance and operations at a minimum. Leadership should give the group a budget and a due date, but the team should be responsible for everything else.

- The first step is always to understand the question of why. For example, identity the problem the company is facing or the opportunities that necessitate this investment.

- Determine if methods such as training or process changes could improve the situation without significant investment. In most cases, no amount of investment on its own is a silver bullet to solve issues.

- Create a list of potential solutions after you determine the required financial outlay.

- Compare and grade all options based on what is essential to the business. For example, primary costs, secondary costs (training, rigging, energy, service/maintenance), timeframe for full adoption, workforce needs, space requirements.

- Research and compare vendors for each option regarding delivery, service and support.

- Calculate an estimated return on investment (ROI) and timeline of this return after you have tallied all the costs. You can do these calculations several ways, so it is wise to seek assistance from a financial professional, especially for larger purchases.

- Consider funding sources and available grants, as different projects may qualify for preferential rates or special grant programs.

- The decision team should weigh the items (costs, delivery, ability to solve problems, etc.) to measure each grade sufficiently. This method will yield an overall score for each option, making it easier to compare solutions that may not be similar.

- Once the decision team tallies the scores, they can focus on the top choice(s) and perform further due diligence, including financing, vendor presentations and visits to customers currently using the solution.

- If the purchase is related to new technology, check out local universities or nonprofits to provide valuable insight and the potential to test the solution.

- Once the decision team makes the final choice, the group should present the recommendation to senior leadership. This presentation should be concise and employ data to share why the team selected this solution. Even if the decision group comprises primarily senior leadership and ownership, developing this presentation will help the group validate the decision. This presentation is also an excellent tool for explaining the investment to the broader team and strengthening grant applications or other financing options.

- The final step before the actual purchase is setting up metrics and a timeline—from submitting the purchase order to implementing and tracking. Remember to track the actual progress and metrics versus a forecasted timeline and desired results to ensure the project’s success and improve your investment process in the future.

While there may be pressure to rush this process, it is vital to have ample time to manage each step, so you gather all of the relevant information. Decisions made on incomplete data will not lead to the best investment option. By creating a solid process, following that process and improving it along the way, you’ve already made a terrific investment for your business.

Leadership should give the group a budget and a due date, but the team should be responsible for everything else.

Putting Process into Practice

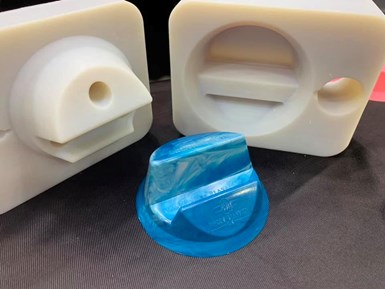

Collaborative research gave Wepco Plastics the opportunity to experiment with 3D-printed tooling technology.

A couple of years ago, Wepco Plastics realized that it needed to explore additive manufacturing (AM). Customers’ desire to get parts faster and cheaper made Wepco realize the need for AM.

The first step was to get people together from sales, finance, design and operations. Next, this team researched the available technologies and how Wepco could use them to gain a competitive advantage.

During this time, team members reached out to the University of Connecticut (UConn), as they had access to and experience with several different additive options. This led to a joint grant application and many months of experimentation.

The knowledge gained from this period was invaluable and came at a very low cost and risk. With this experience, the research team at Wepco determined potential uses, the type of technology needed, costs and possible vendors.

Each member of the team, based on their expertise, was tasked with detailing

Doing their homework with budget, funding, sales and training resulted in Wepco Plastics making the right AM technology investment decision. Here, CFO Charles Daniels shows off the 3D-printed tooling and 3D printer.

things such as a budget and potential funding (finance), business development strategy (sales) and training needs (operations).

The Wepco team established an ROI and timeline, then contacted vendors for demonstrations. UConn returned to provide consultation. The information gained from the research was used to apply for a matching grant and was shared with customers to generate interest.

By performing proper due diligence collaboratively, Wepco was confident that they made the right investment choice, discovered several ancillary added value uses and purchased the equipment with minimal out-of-pocket cost.

Related Content

Editorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreRead Next

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read More2020-2023 Editorial Advisory Board: Meet New Board Member Charles Daniels

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

Read MoreHow to Create an Accurate Budget

Proper financial planning is integral to the success of every mold project.

Read More