Toolholders: An Important Connection between Spindle and Cutting Tool

A review of hydraulic toolholders, toolholders for polygonal clamping and heat-shrinking toolholders makes for an easier selection process.

Although it has minor importance with regard to value when compared to a complete machining center, the toolholder is an important connection between the machine spindle and the cutting tool. The importance in choosing the perfect toolholder is substantial as the quality of the toolholder has a great influence on the results of the complete machining process. The most important requirements for a toolholder are: the gripping force at high speeds, as well as the run-out accuracy and balancing quality, which reduce vibrations. Toolholders need to have a run-out accuracy of less than 0.003 mm. To support the high dynamic of the linear actuation of the machine, a low weight of the spindle, toolholder and tool combination is beneficial to receive superior cutting results.

Customer requirements, with regard to the cutting results of a toolholder, usually are clearly defined, and there are different types of toolholders available on the market that can fulfill these requirements. Depending on the specific application of the customer, it will be possible to find the perfect toolholding system as the different systems offer different technical features and advantages. The following will concentrate on the three kinds of toolholders: hydraulic toolholders, toolholders for polygonal clamping and heat-shrinking toolholders.

Hydraulic Toolholders

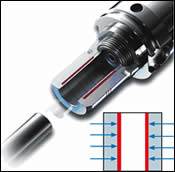

Special toolholding solutions are applied for particular customer solutions. There is one toolholder that can be applied for most of the applications—a hydraulic toolholder (see Figure 1). A hydraulic toolholder uses a different way of clamping the cutting tool compared to systems of conventional toolholders. Introduction of force is done via a screw (with a screw, a piston and sealing). By actuating (turning) the screw, an even hydraulic pressure is generated inside the toolholder. This pressure is transmitted via a steel expansion sleeve, which clamps the tool. With this clamping system, best run-out accuracy and a repeatability of less than 0.003 mm (0.00012") are achieved. As the cutting tool is held in a hydraulic chamber, the toolholder offers superior damping effects, due to the oil in the holder. The user gets a higher surface quality of the workpiece and higher up-times of the toolholder as small eruptions of material—a result of vibrations of the cutter—are avoided. These toolholders are not only maintenance-free and resistant against dirt, but they also are easy to use and offer a safe clamping of the cutting tool.

Toolholders for Polygonal Clamping

The polygonal clamping system is one of those highly engineered devices that is surprisingly simple. A ground polygon shaped bore rigidly clamps a cutting tool in three places (see Figures 2 and 3). For high-speed applications, polygonal clamping is a great solution since the clamping of the tool shank is done by the elastic deformation of the holder. The main advantage of this toolholder is its extremely slim design.

There are two versions available on the market to cover different applications. First, there is a slim version of the toolholder, which stands out with its extremely slim design of the tool shank and its long reach of the tool. It is even possible to use shorter cutting tools with this holder, which in return results in lower costs for the user.

The rigid version of the toolholder has a bigger and stiffer toolholder body and offers better qualities with regard to radial force compensation. Both versions, the slim and the rigid version, can be used with long extensions, which make them even more flexible for difficult machining tasks.

Clamping of the tool or an extension is done within the elastic range of the material of the tool shank. Therefore, there are no restrictions with regard to the lifetime of the tool. Changing a tool can be done within seconds by using an external clamping device. This device does not need any external power source and, therefore, can be used anywhere. This fact makes polygonal clamping systems very interesting for applications that require a frequent tool-change.

Heat-Shrinking Technology

The third toolholding system to note is heat-shrinking technology (see Figure 4). This technology is based on heating up and cooling down a toolholder through induction technology. An induction coil—with some units using a high frequency coil—heats up the toolholder precisely at the area where the tool has to be inserted. After inserting the cutting tool, you need to cool the toolholder, which can be done via a cooling jacket. Cooling down the toolholder will cause the holder to shrink around the cutting tool shank. In this way, the cutting tool is clamped and offers a force conclusive grip, which allows high torques.

The result of the shrinking process is an almost homogeneous tool with many advantages. The main benefits of the heat-shrinking technology are the high run-out accuracy of less than 0.003 mm and high transmissible torques as well as the relatively slim design of these toolholders. If it comes to vibration dampening, hydraulic toolholders or polygonal toolholders offer better qualities than heat shrinking toolholders.

Summary

What kind of toolholding system is the best? An answer to this question cannot be given generally, as this depends on the particular application. When choosing the right toolholder, one basic requirement is that you know the static and dynamic characteristics of the toolholder. These characteristics have to be considered when examining the application and determining safe and effective machining parameters. A comparison of the different toolholders is very difficult, as they offer different benefits with regard to working principle, design and measures. A rating should only be done when considering the requirements of the particular application at the same time. A very rigid toolholder is not appropriate for every application. A toolholder that is perfectly suitable for high-speed machining may not offer the needed values with regard to some other requirements.

Related Content

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

A New Twist On A Toolholding Technology

This toolholder employs expansion technology similar to that used by high-end hydraulic toolholders at a cost comparable to collet-style toolholders.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More.png;maxWidth=970;quality=90)