Prehardened Stainless Mold Steel Optimized by Nitrogen Alloying

To prevent the negative effects of microstructural inhomogenities in some tool steel—such as on machinability, polishability, corrosion resistance and mechanical properties—a new alloy has been created with a more homogeneous microstructure.

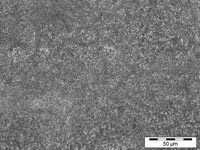

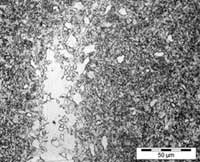

Prehardened 400 series stainless steel (DIN 1.2316) is generally used for calibration tools and mold inserts for the plastic processing industry. Today, plastic products are manufactured by mass production, using thermoplastic and duroplastic bulk materials, which are processed by injection molding, blow molding and extrusion molding. The consumption of plastics has influenced the tool steel market, with a demand for more specialized type of tool steels1,5. Increasing ingot sizes can lead to microstructural inhomogenities—such as carbide segregation and the appearance of δ-ferrite—which have a negative influence on the properties of the typical prehardened stainless steel. Such an inhomogeneous structure is shown in Figure 1a.

Experience has shown that such microstructural inhomogenities have a detrimental effect on properties such as the machinability, polishability and corrosion resistance. Furthermore, there also is a negative influence on the mechanical properties of the material. To prevent these negative effects, a new alloy (Bohler M303 Extra) has been created with a more homogeneous microstructure, and with better mechanical properties as well as better polishability and machinability.

Experimental

New Alloying Concept

Based on the chemical composition of DIN number 1.2316, Thermo-Calc calculations were carried out to clarify the occurrence of the ferrite phase. It has been found that at 16 weight percent of chromium, a delta ferrite phase occurs at forging temperatures up to 1200°C. This effect could be increased by chromium segregation. To reduce the effect of delta ferrite, nitrogen is one of the alloying elements that can be added6. This result was therefore used in the new alloying concept2,3,4.

|

Table 1

|

|||||||||

| Steel |

C

(wt.%) |

Si

(wt.%) |

Mn

(wt.%) |

P

(wt.%) |

S

(wt.%) |

Cr

(wt.%) |

Mo

(wt.%) |

Ni

(wt.%) |

N

|

| 1.2316 |

0.33

0.43 |

max

1.00 |

max

1.00 |

max

0.030 |

max

0.030 |

15.00 17.00

|

1.00

1.30 |

max

1.00 |

|

| N-alloyed prehard stainless |

0.25

0.30 |

0.20

0.30 |

0.60

0.70 |

max

0.030 |

max

0.005 |

14.30 14.60

|

0.90

1.00 |

0.80

0.90 |

+

|

| Nominal chemical compositions of X36CrMo17 and the N-alloyed prehard stainless. Table courtesy of Bohler-Uddeholm. | |||||||||

The partial substitution of carbon by nitrogen reduces the amount of chromium rich M23C6-carbides2. As a consequence, the chromium content of the alloy can be reduced without lowering the chromium content of the matrix at typical hardening temperatures. This measure lowers the risk of carbide segregation.

The nominal chemical composition of the new alloy and prehardened stainless are listed in Table 1.The new alloy can still be produced by the conventional route, allowing for a cost-effective solution. Now, the homogeneous microstructure of the new alloy is shown in Figure 1b, where no δ-ferrite and no carbide segregation were found independent of the ingot position, which corresponds very well with thermodynamic calculations.

Discussion

Hardness

The new plastic mold steel is typically supplied in the hardened-and-tempered condition at approximately 290 to 330 HB, corresponding to about 32 HRc. In this way, a good combination of machinability, hardness and wear resistance is given.

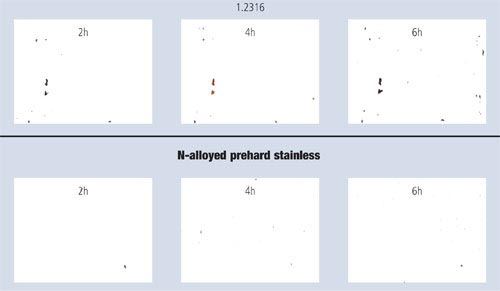

Corrosion Resistance

To examine the corrosion resistance, salt spray tests were carried out according to DIN 50021, see Figure 2. It was found that the corrosion attack was minimized after 2, 4 and 6 hours with the new alloy in comparison to the common 1.2316, which is also a positive result of the homogeneous microstructure. Furthermore both alloys were tested in pitting corrosion measurements. The test medium used was synthetic seawater adjusted to the pH value of 4 using HCl. The pitting potential measured at room temperature of the new nitrogen alloyed prehard stainless is as good—if not better than—1.2316.

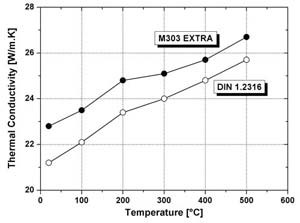

Thermal Conductivity

Improvements in productivity lead to a reduction in cycle time during plastics processing. As a consequence, plastic mold steels with a higher thermal conductivity are required. The thermal conductivity of the N-alloyed prehard stainless and the classic prehardened modified 420 stainless alloy was investigated in the temperature range between 20°C and 500°C. Figure 3 shows that the N-alloyed prehard stainless has an improved thermal conductivity. This improvement primarily results from the chemical analysis and the very homogeneous microstructure.

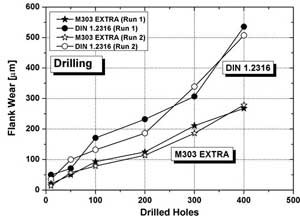

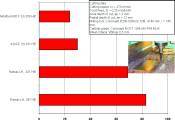

Machinability

To determine the influence of the homogenous microstructure of the new alloy on its machinability, a series of tests were done. The machinability of the classic 420 stainless alloy and the new alloy has been tested by rough milling, end milling, drilling, and gun drilling and tapping. Figure 4 shows the results of the drilling test, which exhibits the advanced machinability of the new alloy in comparison to the previous grade. These positive results are due to the very homogenous microstructure without the appearance of carbide segregation.

Applications

The new alloy uniquely fills the demands that many moldmakers have that are not being addressed today in our marketplace. First, this grade provides good polishability without having to be remelted. This saves on cost for the alloy while still filling the demands of the application. Second, it is a prehardened grade, which saves on heat treatment costs and the concerns that most moldmakers have about the heat treatment sequence and how well that process is performed. It provides a grade ready to be machined and put into operation, which saves time and money for the moldmaker. Also, should the moldmaker need a stainless alloy prehardened, this grade’s unique chemistry gives an overall better corrosion resistance in the prehardened condition than can be obtained in other 420 stainless alloys.

Finally, every toolmaker knows that taking a prehardened 420 stainless steel and then machining it in the hardened condition can present some unique machining issues. The modifications done to this alloy will help the toolmaker get a more consistent result and, while not as easy to machine as a resulfurized grade, is still an improvement over the current non resulfurized types.

The major applications where this grade can be used is in plastic extrusion tooling where better corrosion resistance is required than a resulfurized stainless alloy can provide. It also should be considered for plastic injection molding and rubber molding where the toolmaker in the past has had to use a 420 remelted stainless because he wanted better polishability than a resulfurized, free machining stainless could provide, but wanted a prehardened grade and did not have it. It also can be considered for holder applications where surfaces of the holder are required to have good polishability and yet the toolmaker would want decent machinability in other areas of the holder.

References

1Gerson, F.T.: “Steel Selection—A Decisive Variable in Design and Construction of Plastics Industry Molds”, in: Jeglitsch, F. (Ed.), 5. International Conference on Tooling, Leoben, Austria, p.635-642, 1999

2Lichtenegger, G., Sammer, J., Schneider, R.: “Entwicklung eines stickstofflegierten Werkzeugstahles mit höchster Korrosionsbeständigkeit bei größtmöglicher Verschleißbeständigkeit und Zähigkeit”, 1999

3Bauer, M.: “On the Application of Corrosion Resistant Steels for Plastic Molds”, in: Jeglitsch, F. (Ed.), 5. International Conference on Tooling, Leoben, Austria, p.669-676, 1999

4Houdremont, E.: “Handbuch der Sonderstahlkunde”, Springer Verlag, p.1298, 1956

5Ernst, C.: “Optimized Steel Selection for Applications in Plastics Processing”, in: Bergström, J. (Ed.), 6. International Tooling Conference, Karlstad, Sweden, p.271-284, 2002

6Ernst, C., Raschke K.: “Nitrogen alloyed tool steels”, in: Berns H. (Ed.), International European Conference on Tooling Materials, Interlaken, Switzerland, p.481-499, 1992

Related Content

VIDEO: Innovative Materials Boost Mold Efficiency

Advancements in metal 3D printing and stainless steel optimize mold building for diverse, high-demand industries.

Read MoreProject Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology's Christina Fuges talks with General Motors' Shane Appel about a project testing a new P20 steel grade's dimensional stability.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreVIDEO: Qualifying Modified H-13 for 3D-Printed Tooling

Next Chapter Manufacturing and International Mold Steel discuss their partnership to qualify a modified H-13 for tooling applications.

Read MoreRead Next

Development of a New Mold Base Stainless Steel

Due to the intensive machining practices that must be performed on mold bases, if machining time and costs can be reduced, significant savings can be realized. A premuim free machining stainless holder steel has been developed that has optimized chemistry and processing, which lead to greatly improved machinability as well as other important properties.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More