The Evolution of an Invention

The next generation of the Tie-Not balloon tying device—developed, designed, prototyped and molded by a mold base shop owner and his wife—posed many challenges due to the complexity of the mold design.

Several years ago, Wayne Sikorcin, owner of Craftsman Tool & Mold Co. (Aurora, IL)—a moldmaker turned mold base builder—and his wife Laura invented a device that would tie a knot on a water balloon. Since then, the Tie-Not has evolved into the Tie-Not Filler, a device that attaches to a garden hose to fill and tie the balloon. Much like the original invention, the couple experienced a number of triumphs and tribulations getting this product to market, collaborated with a number of valued colleagues and new contacts, and learned valuable lessons along the way.

Once again, the Sikorcins worked closely with Scott Smith, Managing Partner of SalesPro, Inc.—a full-service sales consulting firm—for his marketing savvy and sales expertise. They also benefitted from the skills of product developer Matt Kusz (kuszideas.com).

The Beginning of the Evolution

After the Tie-Not debuted at the 2010 Toy Fair, Wayne contacted Pelco Tool (Glendale Heights, IL) to modify the mold; going from a four- to eight-cavity tool and adding the patent number, product name and simpler directions on how to use the device—all feedback he received from the trade show. When this step was complete and the Tie-Not began selling in specialty retail shops across the nation, it was time for the next generation of this product.

Wayne’s idea for the Tie-Not Filler was based on paranoia. “At the Toy Fair, some attendees told me to be prepared for the fact that people would try to steal my idea,” Wayne recalls. “So

I went into my little cocoon and thought, ‘How else are people going to tie balloons with the tool?’ So I started coming up with different methods, besides the one we patented. “Then Laura said to me, ‘Well, you figured out how to tie it, so why don’t you figure out how to fill it easier? The fillers still stink.’”

The couple brainstormed and got the idea to fill it—and tie it—right off of a garden hose. “After that the wheels started turning and we went through a number of processes,” Wayne notes. “From the mold end of it, I contacted Tim Holland, President of Metro Mold & Design (Rogers. MN).”

Prototyping/Market Testing

Wayne worked on some sketches and shot a video with a makeshift prototype that he made. He discussed the idea with Tim at Metro Mold. His initial design had the filling device and the tying device as one part. Tim’s idea was that the tool could be done easier if Wayne and Laura removed

the tying device from the filler—still using the existing tie-not tool and fit it into the filler body. “I loved this idea because it allowed the tool to be used in two ways,” Wayne explains. “The balloons could be filled and tied, or just tied. Then the kids could take the tying tool out and change colors if they wanted. It made it useful and fun.

“Tim suggested using an outside designer because he felt that if a moldmaker designed it, it would be functional, but it might look like an outhouse,” Wayne continues. “He thought it should be ‘sexier’ to have more visual appeal. He referred us to Matt Kusz. Matt developed some concepts and worked up three—a swordfish, dolphin and a water drop. Then we did a few tests with local kids in the neighborhood on what they liked and it was almost unanimous for the water drop, although they did not say why. We thought it would be better to not be gender-specific and stay with a general design that would have mass appeal. This part of the process took about two months.”

Re-Tooling

The original Tie-Not tool has the pocket facing up when tying. When using it in the new filler, it needs to be inserted 180 degrees. So Wayne went back to Pelco Tool to add a keyway for orientation purposes—so it could only be inserted one way into the filler to avoid any confusion to the consumer.

This time, Metro Mold quoted them on a four-cavity tool and an eight-cavity tool. Wayne and Laura opted for the four-cavity tool for cost reasons, with Wayne and Tim choosing the design.

“We spent two months in design, which only allowed 12 weeks to build the tool and produce parts to get ready for the New York Toy Fair 2011, which was held last February,” Wayne notes. “It was very important to launch the product at this time to get the Tie-Not filler into the stores by the spring. The new design was very complicated—it was an unscrewing mold with multiple slides.”

Due to time constraints, Metro Mold outsourced the slides and some other components to Mold Craft (Willernie, MN), Laura adds. “We used companies that are AMBA members because we have forged relationships with them over the years.”

Once again, the couple used Wayne’s company, Craftsman Tool & Mold—which specializes in large, close tolerance, complex, high precision, custom mold bases for a variety of industries—for the mold base.

Another difficult area of the mold design that required a lot of collaboration was retaining the piston, Wayne notes. “There are three molds for this tool: the filler body, the piston and the cap,” he explains. “To keep the cap retained on the filler body, I hired another outside consultant. I knew that the engineering for that was beyond our knowledge, so I outsourced that technology. We found out that the arrow snaps were underengineered. Garden hose pressure is 70 to 80 psi and our caps

were popping off under normal garden hose pressure.”

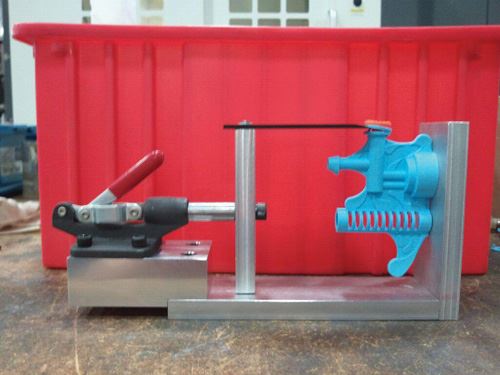

Their first solution was to try different materials to add rigidity to the arrow snaps, which helped, but did not resolve the problem. It was also discovered that the arrow snaps were being stressed during assembly of the product. “Project Manager Myles Marquette and the Metro team came up with an assembly fixture to ensure that the arrow snaps would not be over-stressed during assembly,” Wayne says.

Wayne also made another change to the mold to limit water leaking while filling the balloon by elongating the front nozzle of the filler. “I believe we are the first people to ever hang a balloon

from a filler,” he notes. “Most people fill their balloon up, pull it off and tie it with their fingers. We actually hang the balloon from the filler so the neck of the balloon elongates and that’s what I did to the mold for the filler nozzle. I elongated it to shut the water off to keep it from spilling out by changing the geometry. I sent the design to Matt who implemented it into the part design and the mold had to then be re-cut by Metro Mold.”

Laura weighs in on this part of the process. “The initial Tie-Not Filler had some issues with the cap popping off,” she comments. “We got some negative feedback with our online sales and had some returns. The test products we had worked well because they were carefully assembled, so we had no failure rate at that time. We discovered this problem with the first large shipment and the problem was intermittent, which made it difficult to pinpoint and caught us by surprise, and it is very

hard to manage online sales. People will post their feedback online—saying things like this product doesn’t work without giving you the chance to rectify it.”

“The bottom line is Tie-Not put about 500 products out there that were faulty and it took us about a month to lick our wounds and figure out the assembly problems that we had that were causing the issue,” Wayne adds. “Myles from Metro Mold worked with us directly on resolving these issues and he came up with several great ideas. We came up with a methodology to control the assembly issues, which were being caused by human error. We changed the material type so it would return

to its original position and not get overstressed. And Myles suggested we use a control during the assembly process, which was then a fixture that Metro Mold designed. All of these changes helped to rectify the problem of the cap flying off.

Our defective rate went down to a very small percentage and the online feedback has drastically improved.” Wayne and Laura also had a prototype made; primarily to get an idea of how the Tie-Not filler would work and they wanted some quick samples to show Wal-Mart because they

were given an opportunity to reach out to the buyer in a small window of time. They made four up-front. “The consistency and rigidity of the material the prototypes were made from was a failure and it unfortunately couldn’t be used,” Laura says.

This is all part of the product development process. A lot of times you will start with the prototype before the mold so you can get an idea of what it looks like.” Wayne adds, “I would do so many things over if I had a chance to do it all over again.”

A New Partnership Builds Brand Recognition

After the 2011 Toy Fair, Tie-Not was led to the largest distributor of water balloons in the country—Imperial Toys. Wayne and Scott demo’ed the Tie-Not for Imperial. “We not only gave them a live demo in their offices, we had the president demo it himself,” Smith states. “They are focused on being a top water balloon seller, so we explained that they should look at filling and tying them faster. The faster balloons are filled and tied, the more they will sell. Our timing was perfect. Imperial was introducing a water balloon line aimed at a more mature market (Kaos) and Tie-Not was a perfect fit,” Wayne elaborates.

“We began negotiations. Scott and I recalled a speaker at the 2010 AMBA confevention who spoke on defending your price, showing your value rather than cutting your price. Scott used

these skills when he negotiated the contract. Scott stood hisground and Imperial accepted all of the terms we laid out.”

Laura adds to Wayne’s sentiments. “It helped us immensely to have had that information from the AMBA. If you are armed with the knowledge that what you have to offer the market is not already out there, you don’t need to give your goods away. I think some American companies are doing just that.”Laura believes that in Tie-Not’s case, it is important to show consumers what the product does in order to sell it. “It is not going to sell just sitting on the shelves,” she says. “Imperial has

a huge marketing department and they will be launching our product in the spring with TV spots as well as end caps with video screens in the stores.”

Tie-Not also is purchasing some of the items in Imperial’s Kaos line to hopefully get them on the shelves of the specialty stores Tie-Not is currently in, since Imperial targets mass retailers. “Right now there are three items (single pack, two pack and filler pack) in the Tie-Not line,” Wayne comments. “Hopefully by the end of 2102, there will be eight.” Wayne notes that his ultimate goal from day one was name/brand recognition. “When kids or adults think about filling water balloons I want them to think Tie-Not,” he emphasizes. “I want it to be like Kleenex.”

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreRead Next

Invent a Product—Not Just Its Mold

When Wayne Sikorcin, owner of Craftsman Tool & Mold Co. (Aurora, IL)—a moldmaker turned mold base builder—got frustrated tying water balloons at a family picnic several years ago, he decided to turn that frustration into innovation by using his moldmaking background, experience and connections to develop, design, prototype and mold a device that would tie a knot on a water balloon.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More