MMT provides you with a comprehensive compilation of mold component, hot runner and machining products/services below for the month of March. Companies include:

- Meusburger

- GF Machining Solutions

- Hasco America

- PFA

- DME

- Ewikon Mold Technologies

Remember, this article represents only a small portion of the the new/proven products we’ve posted, so head on over to “New Tech” on the homepage, or check out the 23 additional hot runner and mold component offerings in MMT’s April print issue roundup.

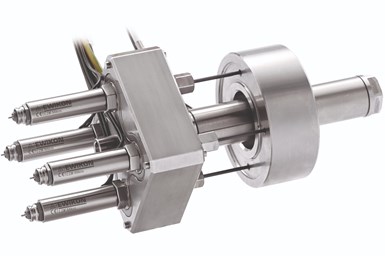

The Ewikon L2X-Mikro high-performance hot runner system for small injection molding machines is now available as a compact 4-drop version with valve gate technology for shot weights around 0.05 g per nozzle. The system uses synchronous plate technology for simultaneous actuation of all valve pins. Due to the very compact design of the drive technology, it can be easily integrated into all common mold sizes for small injection molding machines.

Hasco America’s new, low-leakage temperature control system offers user maximum safety during uncoupling, and improved tightness and durability.

Featuring flat end sealing surfaces, the system shuts off on both sides to enable low-leakage and a clean open and close under pressure. One-handed quick-release couplings showcase a long and precise guidance for the sealing nipple. This guarantees safe and independent coupling with a maximum flow rate and a small, low-pressure drop.

With PFA’s Switchmax mold wiring solution, it is possible to connect all core position sensors into single press inputs for set and pull, and provide operator side LED light indications for core positions. Secondarily designed for blocking unwanted signals, the system includes cross-connected sensor verification for mechanical switches, 3-wire PNP integration and relay sensor adapters for universal IMM connections.

Hasco America’s thermal protection hose Z8570 meets injection mold temperature control requirements for greater cost-efficiency and occupational safety during the product process.

Hoses are made up of braided textile glass fiber and a silicone foam coating for optimal thermal insulation and excellent mechanical protection. The material’s internal sliding properties allow it to be more easily pulled over hoses and bridges.

The DME LT-Series LifeTime Roller Lock features a new and improved design for molders facing improper mold alignment, with availability in three advanced materials to meet a range different molding application requirements.

A tri- and penta-lock interlacing lock design is said to deliver a more precise location and holding power of the final lockup. A longer male portion and new carbide rollers ensure the mold halves align easily, which protects against crossover shutoff. Moreover, the LifeTime Lock is machined to precise tolerances, enabling each lock to be fully interchangeable within the same lock series, ideal for shuttle and rotary mold applications.

Hasco America’s proven range of plastic, aluminum and brass spiral cores has now been extended with the steel grade 1.4305. Specifically, the stainless steel spiral cores Z9611 (single-threaded version) and Z9612 (double-threaded version) are now available, and round off the company’s recently launched range of stainless steel cooling units.

Excellent resistance and electrochemical corrosion ensure effective and homogeneous conformal cooling along the bore wall for medical and cleanroom technology. Further, high media resistance guarantees longer maintenance intervals, allowing for more efficient production of plastic parts.

A cost-effective alternative to existing slide retainer solutions, Meusburger’s E 3050 leaf spring roll stopper possesses a compact design which enables retaining forces up to 140 N, proving it ideal for holding large slide bodies in their end position. A wide range of applications are covered via two variations and three different leaf spring thicknesses.

The roll inside the roll holder locks under tension when the mold is opened. The leaf spring’s recess ensures that the slide body is held in a precise position without play. In addition, the freely mounted roll, made of bearing steel, and the nitride leaf spring ensure minimal friction for maximum service life. Meusburger slide retainer can be used at temperatures of up to 200°C.

Using tension instead of friction, Hasco America’s zinc-coated wedge lock washers Z693 reliably secure screw connections and eliminate the bolt-loosening effect when exposed to vibrations or heavy loads.

The reusable, two-part washers, bonded in pairs, guarantee a positive lock of the screw even at low torque. Maximum service temperature is 200°C. Washers also enable reliable functioning, including with lubricant usage. Hasco’s standard mold units is supplemented by eleven different sizes for common screw diameters.

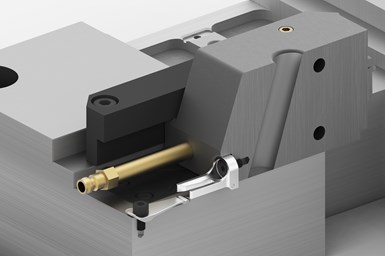

PFA Inc. offers a quick mold change (QMS) system ideal for non-magnetic mold clamping with consistent force and mechanical clamping advantages.

The PFA Hydra-Jaws QMC system replaces common mechanical clamp systems and bolt-through fastening methods with its flexible hydraulic mechanical clamping system for use with a variety of mold base dimensions and base materials.

Hasco’s hot runner control unit Primezone H1281 offers moldmakers a reliable system with high control accuracy, an intuitive interface and comprehensive diagnostic functions that guarantees stable processes and quality injection-molded parts.

Monitoring functions protect the controller, the hot runner system and the mold. Integrated mold diagnosis checks the wiring of hot runner components before start-up, and recognizes potential assembly errors, preventing mold damage and expensive repair costs.

Targeting mold and die makers in the ICT/EC segments and medical device manufacturers, GF Machining Solutions has launched the new MILL P 500 three-axis vertical milling machine in North America. The MILL P 500 is said to deliver high levels of precision, reliability over extended machining periods and exceptional productivity for die casting, high-temperature forging molds and dies, cold forging dies and extrusion dies applications. Further, the machine reportedly delivers superior part surface finishes, extreme contour and position accuracies and dimensional precision critical for the production of injection molding and stamping dies and sinker EDM electrodes.

.jpg;maxWidth=970;quality=90)