Photo credits, clockwise from top left: Heidenhain, Kennametal, Seco Tools and Siemens

The next chapter of MoldMaking Technology’s technology roundup is here. More and more technology is introduced to the moldmaking industry every day. With so many different products, processes and services to keep track of, MMT makes it easier with a monthly technology roundup, providing readers a rundown of relevant technology on the market.

This month’s roundup focuses on metalworking, including cutting tools, machining and more. There are also a few highlights including automation and software technology.

To check out tech roundups from months prior, please browse the “New Tech” section of the MoldMaking Technology website, or look up “Technology Roundup” in the homepage’s Search bar. For more information on a product featured below, click on the title link for the respective product.

Machining

Heidenhain Corp. spotlights the new TD 110 tool breakage detector, specially designed for quickly sensing tool breakage during use within a machine tool. Providing contact-free inspection of drill bits and end mills, it can determine whether a tool is broken off by more than 2 mm as it passes within a machine tool, yielding significant time and money savings.

The TD 110 tool breakage sensor can be placed in the work envelope so that it is fast and easy to reach during the tool change, according to the company. The inductive sensor detects tools as they pass by while spinning at their operational speed. The TD 100’s rapid scanning technology ensures even very small tools made of HSS steel and carbide are detected.

Photo Credit: Mitsui Seiki

According to Mitsui Seiki USA, a builder of jig borers, the market demand for these ultra-precise machines is on the rise. “Jig borers typically last 25 to 30 years,” Mitsui Seiki USA’s Bill Malanche, COO, says. “Now seems to be the time that people are retiring their legacy machines and looking to buy new.” Mitsui Seiki’s newest line, the J12/J/16 jig borer series, combines large capacity and high precision to meet the increasing need for accuracy for machining workpieces such as molds and castings. The machines offer Y-axis stroke of either 1,250 mm or 1,600 mm, with standard table sizes of 2,400 mm × 1,250 mm or 2,900 mm × 1,600 mm.

Photo Credit: DN Solutions

DN Solutions’ SVM 500L is joining the company’s family of vertical machining centers. The SVM 5100L is the “big brother” of the SVM 4100 and fits into the company’s lineup between the DEM and the DNM series.

Like the smaller SVM 4100, DN Solutions says the SVM 5100L is optimized to provide shorter cycle times by reducing the acceleration and deceleration times of the XYZ axes and spindle. This feature aims to minimize non-cutting time.

Siemens Industry makes available its mid-range CNC, the Sinumerik 828D, with a version 4.8 operating system. With the version release, Siemens now offers an array of new hardware and software solutions for its integrated Sinumerik portfolio, comprising integrated industrial software and automation technology designed to enable machine tool manufacturers to leverage the full productivity potential of the digital factory in a mid-range control.

Sinumerik 828D is a compact, panel-based CNC designed for turning, milling and grinding operations. It is offered in vertical and horizontal models for highly flexible machine design integration and enables optimum surface finishes with 80-bit nano floating point accuracy.

Cutting Tools

Photo Credit: United Grinding

Walter, a brand of United Grinding, introduces Laser Contour Check, a novel noncontact option to tactile measurement in tool grinding and eroding machines, common equipment used when making molds.

The new blue laser, paired with an intelligent measuring system, provides high-precision measurement of various tool parameters on cylindrical tools with diameters from 1-52 mm. Since it does not contact the surface, the Laser Contour Check avoids possible damage to cutting edges or measuring errors that can occur due to wear on the probe tip during tactile measurements.

Manufacturers must overcome specific machining challenges cost effectively. With this goal in mind, Seco Tools offers its comprehensive range of hydraulic chucks and accompanying reduction sleeves in three versions, each able to accommodate several tool shank size variations for reduced tooling inventory. With 360° tool-shank holding strength and precise centering, the equipment ensures reliability, along with exceptional machining performance and maximized tool life.

For simple, easy-to-use, versatile toolholding, the three versions of Seco hydraulic chucks include the HC Conventional, HCR Reinforced and the HCS Slim.

Photo Credit: Greenleaf Corp.

Greenleaf Corp. has announced Greenleaf-360, a new line of high-performance solid carbide end mills to complement the XSYTIN-360 line of solid ceramic end mills. Greenleaf-360 end mills combine a proprietary flute design with a high-performance carbide substrate for fast and efficient material removal with less stress induced into the part. A combination of strength, toughness and heat resistance enables machining capabilities from roughing to finishing with extended tool life and predictability, well suited for materials in the aerospace, automotive, die and mold, medical and power generation industries. Speed and feed performance are said to be 25-50% higher than competitive cutting tools.

Photo Credit: Ingersoll Cutting Tools

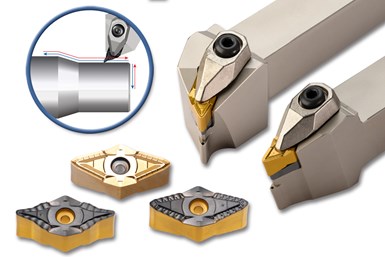

SuperTurnZ offered by Ingersoll Cutting Tools is an innovative system for multi-directional turning that utilizes the front and back cutting edge of a four-corner insert in a single tool. It reportedly represents a highly productive alternative to conventional turning; traditionally, where 80- and 35-degree corner inserts are fed in the same direction, SuperTurnZ uses all four directions available on conventional two-axis lathes (+Z, -Z, +X, -X) to maximize material removal.

Parlec, a member of Techniks Tool Group, has released a line of U.S.-made BMT65 toolholders made from ductile iron. According to Parlec, ductile iron has 6.6 times more vibration damping properties than alloy steels, enhancing cutting tool performance and extending tool life. In addition, the higher graphite content of ductile iron reduces friction and prevents premature wear of the toolholder.

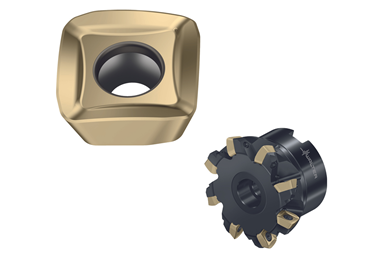

Walter USA reveals an SDMX indexable insert for its Walter M4002 high-feed milling cutter. Consequential to its highly positive geometries, the square positive, universal insert lowers power requirements. It is thick for maximum process reliability and provides four cutting edges per indexable insert with a curved cutting edge for complete stability.

There are two indexable insert sizes with facet — SDMX0904ZDR-E27 and SDMX1205ZDR-E27.

Photo Credit: Sandvik Coromant

Global metal cutting company, Sandvik Coromant, has launched an upgraded CoroDrill 860 cutting tool assortment to offer moldmaking customers improved productivity in drilling ISO P steels while significantly improving tool life.

The advanced -PM geometry is particularly ideal for medium hardness die steel in the mid-45 RC range (250-450 BHN). Sandvik notes that moldmakers would benefit using the 860-PM for higher volume production applications without the need to change out the tool as often, thereby reducing cost per component being drilled.

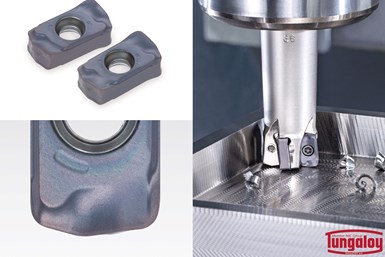

Photo Credit: Tungaloy America

Tungaloy America has expanded its DoFeed high-feed milling cutter series by adding six LNMU0303UER inserts. DoFeed, a high-feed milling cutter series, features economical double-sided inserts with four cutting edges, offering a wide variety of cutter body diameters and styles.

New LNMU0303UER inserts are available in Size 03 and designed to provide long tool life, the company says. These UER inserts are interchangeable with existing ZER inserts on the same cutter body.

The LNMU0303UER inserts are designed to provide a smaller approach angle than existing LNMU0303ZER inserts when set on the cutter body so that the insert generates thin chips.

In mold and die applications, process stability, high-surface quality and tool life are all key for optimal efficiency. This is why Kennametal has introduced the PVD-coated KCK20B and KCKP10 indexable milling grades for higher wear resistance, up to 30% longer tool life when machining cast iron and compacted graphite iron components and no rework needed. Both grades are said to offer higher productivity and consistent, repeatable performance during roughing, semi-finishing and finishing operations; the inserts also work well when profiling and copy milling cast iron and steels up to 45 HRC.

The M.A. Ford TuffCut XV Series XV5CB is said to be a stable, reliable solution for deep, dynamic milling applications, especially developed for mold builders. The five-flute chipbreaker end mill was designed to deliver exceptional metal removal on steels and stainless steels. Offered in both 3xD and 4xD length of cut options, M.A. Ford says the XV5CB increases productivity through its aggressive stepover capabilities.

The tool’s combined variable pitch geometry flutes and thick core design minimizes harmonic vibration and increases strength. Along with the company’s staggered chipbreaker technology — to reduce cutting force and extend the life of the tool — a good balance can be reached, the company contends, increasing machining performance.

PCD helical ballnose cutting tool. Photo Credit: ANCA Inc.

According to ANCA Inc., used in the right application, a polycrystalline diamond (PCD) cutting tool can last up to 20 times that of an equivalent carbide tool. The company unveils a new generation of solid PCD helical end mills and drills made on ANCA’s EDGe machine to further extend this advantage, tooling solutions that can ultimately deliver improved productivity and quality when having to tackle tough machining requirements and complex geometries like those found in the mold and die industry.

Software

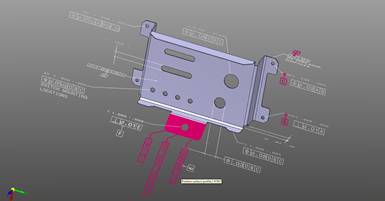

Autodesk Inc. has made available the Production Design Extension and Simulation Extension, which have been added to Fusion 360, the company’s integrated 3D CAD, CAM, CAE and PCB software for product design and manufacturing. Initially highlighted during Autodesk University (AU) in 2021, these extensions improve the platform’s performance, user experience and efficiency.

Photo Credit: Kubotek Kosmos

Supply chain software provider Kubotek Kosmos has announced the 4.0 release of the Kubotek K-Compare and K-Display software products. This release provides updates to CAD file readers, user interface improvements and several new functions for each product. The new releases are available for customers to download immediately.

For example, reading of 3D CAD files across all 4.0 Kubotek software programs has been updated to support new versions of ten CAD file formats.

Automation/Machining

Photo Credit: Grob Systems

Manufacturing systems and machine tools producer Grob Systems Inc. announces a new versatile and customizable automation solution which further improves machining productivity on a range of Grob machining centers. The PSS-T300 Tower Pallet Storage System, which enables automation and increases part production throughput, is the latest entry to the wide range of Grob automation solutions for creating flexible manufacturing cells.

Especially well-suited for smaller shops where one operator is responsible for running multiple machines, the PSS-T300 Tower Pallet Storage System automatically removes and loads pallets, offering unmanned 24/7 operations or lightly attended shifts when paired with Grob G150, G350 and G350a five-axis universal machining centers.

.jpg;maxWidth=970;quality=90)