MoldMaking Technology has compiled the latest mold builders offering their services, as well as hot runner, software and inspection/measurement technologies technologies being offered to the moldmaking industry. Below is a sneak-peek of some prominent companies that offer products in these categories and appear in the upcoming August 2021 issue, including Wepco Plastics, Convenio Technologies, MoldTrax, United Grinding, Meusburger and more.

MMT publishs new/proven products/services on a daily basis, so browse our “New Tech” section on the homepage of our website, or find them via the website search bar. Follow each title link below for the full product post.

For a list of more than 70 products/services from 11 different categories, see “Technology Roundup: Moldmaking Technologies You'll See in the 2021 Sourcing Guide.”

Further, keep up with products and services that will be showcased by exhibitors at Amerimold 2021 in September here.

Mold Builders

Concept Molds is a premier manufacturer of high-quality custom precision molds for the automotive, medical and industrial markets. With more than 30 years of experience, its team offers customers the knowledge and dedication to build complex tools. Attention to detail, commitment to quality and superior customer service and passion for building intricate molds are all features the company emphasizes.

Convenio Technologies is a tooling solution provider for the engineering, design, development and on-time launch of qualified high-performance tooling systems. Representing and providing a complete development solution through a small select group of like-minded companies — starting with design/assist, integrating design-for-manufacturing, comprehensive process simulation, on-time tool build/delivery, process development and mold approval.

MoldTrax LLC is a mold maintenance tracking software company that offers consulting services under its maintenance capabilities assessment (MCA) offering, and hands-on education opportunities throughout the year for certification in mold maintenance and repair, hot runner maintenance and repair, tool room manager, component repair, texturing design and repair and a component repair and texturing combo.

M.R. Mold & Engineering Corp., known globally for its expertise in liquid silicone rubber (LSR) for the medical industry, has been building LSR and plastic injection molds for more than three decades. With its recent acquisition of new equipment and pending ISO 9001-2015 certification, M.R. Mold says it expects to enter into the aerospace and defense industries.

Wepco Plastics specializes in three-week prototype aluminum tooling and short-to medium-run plastic injection molding with aerospace machining, fixturing and secondaries. Aluminum tools are guaranteed for 50,000 shots. From concept and design, to 3D printing through mold manufacturing and part production, the company says it is a one-stop shop for quality aluminum tools and plastic parts.

FactoryFix is an online platform that matches vetted manufacturing workers with companies seeking specific skill sets. Unlike conventional online job boards or recruiting services, FactoryFix reportedly provides additional value to manufacturers beyond simply suggesting candidates, such as providing a personalized career coaching experience to enhance and coordinate professional development.

Kruse Training Inc., a developer of interactive online training programs for injection molders, part and mold designers and process engineers, partnered with Moldex3D to launch its Molding Defects Level 2 interactive training section to its Circle of Knowledge online training program.

According to the company, the goal of this Molding Defects section, in addition to teaching the causes of common molding defects and how to prevent them, is to fill knowledge gaps and ensure better knowledge flow between designers and engineers.

To further enhance customer benefits of its machine rebuild and remanufacture services, United Grinding North America now offers customers with older Walter Helitronic Power Series tool grinding machines the option of new advanced automation technology seamlessly retrofitted as part of a machine rebuild. The option replaces original gantry beam-type loaders with faster, more productive FANUC LR Mate 200i robots, the same as are featured on brand new Walter Helitronic machine models.

Miscellaneous

RJG’s injection mold networking software, The Hub, now has a new application available: The Hub for Mold Transfer.

The Hub connects RJG’s CoPilot process monitoring systems to a single interface, enabling users to access all plant information globally, make data-driven decisions, increase visibility, decrease liability and improve operational efficiency. Alternately, RJG says the Hub for Process Analytics enables users to access real-time data from anywhere, review and export reports, view job audit reports, replay historical data and more.

The Mitutoyo America Corp. has added the PJ-Plus Series Profile Projector to its lineup of metrology products. The Mitutoyo PJ-Plus is a new series of profile projectors that uses LED lighting and provides reliable measurements in manufacturing site environments, according to the company. Mitutoyo states that the PJ-Plus provides stable dimension and angle measurements in harsher environments than many conventional models can handle, such as manufacturing and processing lines.

Zeiss has released the Metrology Extension (MTX) for Zeiss Xradia 620/520 Versa. The extension enables dimensional measurements that are more accurate than conventional X-ray computed tomography (CT) technology, according to Zeiss.

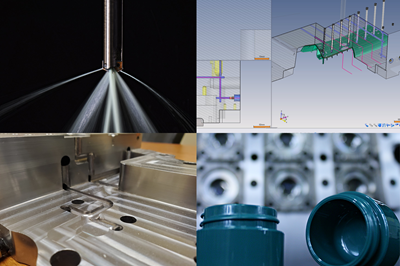

Meusburger says the FH hot runner mold, which includes a complete mold base and hot runner system, can be configured online in a few clicks with customizable aspects, as well as standardized ones, to speed design and delivery. Once configured, the system can be ordered as a complete package and delivered, with 3D data also available for download.