Stressed? Join the Club!

Stress is something that everyone has in common.

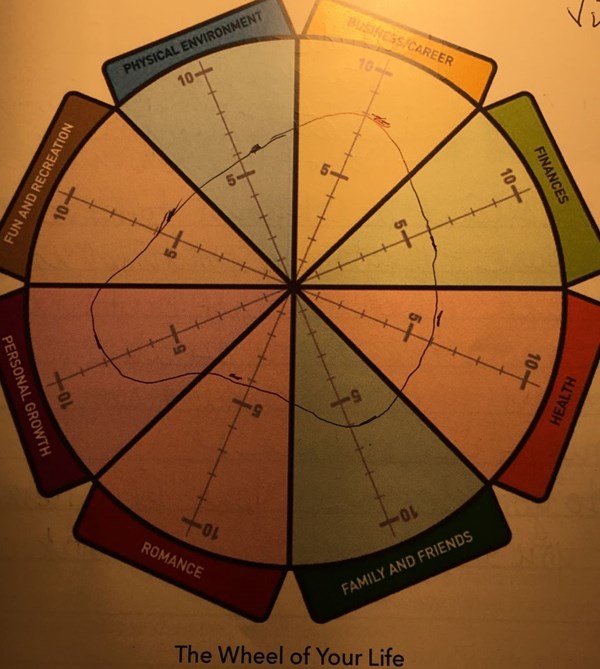

Stressed? If this was the wheel of your life, how would you rate each aspect? If you connect the dots, you'd most likely find something like the above--a bumpy circle of imperfection. But there's hope!

Stress is something that everyone has in common. That was driven home for me at the American Mold Builders Association’s (AMBA) annual conference in Cleveland earlier this month, when I attended a Game Changers session presented by Adam Timm. He is an author, speaker and “stress resilience subject matter expert,” and he gave a very abbreviated, but revealing, talk about stress management. I’m not saying the other sessions offered were left with only crickets chirping, but Timm’s session drew a standing-room-only crowd.

Timm’s talk is given from the heart of his own formerly very stressed existence as a 911 operator in Los Angeles. He held that job for more than 10 years and says he reached a tipping point along the way that forced him to come to terms with the daily stress and find ways to manage it before he went off the deep end. I wanted to share some of his ideas and techniques with MMT readers because I know moldmakers, suppliers and molders are one stressed-out group of individuals.

Each person in the session had a workbook, and in it, Timm asked us to define stress as we each see it. He then asked each person to create a metaphor for stress. I thought of stress as if it was being in a room of fun-house mirrors. Another person said it was like being trapped in quick sand, and so on. Timm asked us to list our top three stressors in order to identify that which kept us from moving forward in life, job and other areas of our lives. He also asked us, “If you could create a life of less stress in six months, what would it look like?” We were asked to describe it on paper.

All the while, Timm was also teaching us about resiliency. What is resilience? It is “the ability to bounce back in the face of hardship or adversity. It’s the ability to perform at your best on a consistent basis.”

That’s what we all want, isn’t it? To be resilient is to take power away from the stress that bogs us all down. Timm calls it “honoring your values,” and he asked us to list some of the values that mean the most. What values are priorities in your life? What are the five keys for making this week, and every week thereafter, your best week ever? Timm shared those keys:

- Breathe five to 10 minutes a day

- Visualize – Use a compelling vision for the future

- Action – Learn to say NO

- Gratitude – Dwell in it, practice it, write 10 things you are grateful for, every day

- Celebrate oneself – Celebrate our wins. Joy and stress cannot coexist, says Timm.

Timm closed by sharing several characteristics that resilient people are known to possess. They are as follows:

- Self-awareness. They have emotional intelligence.

- They understand what their hot buttons are and those of others.

- They listen more than they speak.

- They help others with empathy and compassion (versus obligation).

- They get out in nature.

- They remind themselves why they do what they do for a living. Timm says it’s important to remind yourself what you stand for.

I really liked this quote that was printed in the workbook, and hope everyone reading it will, too. It says, “More than education, more than experience, more than training, a person’s level of resilience will determine who succeeds and who fails. That’s true in the cancer ward, it’s true in the Olympics and it’s true in the boardroom.” – Dean Becker, Harvard Business Review, May 2002

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More