Seeing and experiencing manufacturing firsthand is almost always the most effective first step in engaging young people in a discussion about rewarding careers in moldmaking. Janler Corp. (Chicago, Illinois) understands that very well and seized an opportunity to invite 12 girls, all middle school students, to tour its facility.

The girls were participating in the Camp GADgET (Girls Adventuring in Design, Engineering and Technology) summer program where, for two weeks, they get hands-on exposure to the world of engineering and manufacturing. Part of the program, which is put on by the Triton College Engineering Technology Program, includes visiting various manufacturing companies in the Chicago area, of which Janler was one.

Proving what a small world manufacturing can be, Chuck Klingler, vice president of sales at Janler, says the idea to do a tour with Camp GADgET stemmed from his sister, Janler President Carol Ebel’s extensive involvement with the Technology and Manufacturing Association (TMA) in Schaumburg, Illinois, and his own active involvement with the American Mold Builders Association (AMBA) Chicago Chapter. “Triton was conducting a Camp GADgET program at Lake Park High School (Roselle, Illinois), and we have worked with Assistant Principal Ian Smith via TMA programs in the past. We met Antigone Sharris, who is Triton’s Engineering Technology Program Coordinator, in the student pavilion at IMTS2016 where the Chicago AMBA was exhibiting. She created Camp GADgET,” he says. Add to that the fact that the Chicago AMBA had awarded Triton’s GADgET program with scholarship money to support its endeavors, and that Klingler was named the Society of Plastics Engineers (SPE) 2018 Mold Maker of the Year, which came with a $500 scholarship that he gifted to Lake Park High School’s new Engineering and Precision Machining Technology class, and the world seems even smaller.

Getting GADgET Going

Sharris created Camp GADgET in 2011. “I did it because I saw very little traction with female engagement in tech programs and, since I saw way too many males in the tech programs in the high schools, I knew I had to do something to help change that,” she says. To date, more than 200 young ladies have participated in the program, and in the summer of 2019, GADgET had participation at Triton College, College of DuPage in Wheaton, Illinois, and at Richard J. Daley College in Chicago. Sharris limits the class size to about 16 girls so that each participant gets the best possible experience. She calls GADgET an unstructured structured learning environment because she begins the camp with a few structured activities for the girls to do, but then they are on their own to create their own maker projects, receiving guidance when needed.

Academia is so heavily structured that the kids are not allowed to be creative because teachers aren’t allowed to be creative.

“Academia is so heavily structured that the kids are not allowed to be creative because teachers aren’t allowed to be creative,” Sharris says. “Everything becomes cookie cutter turnkey and the kids don’t really connect anything they have learned to the real world.” She believes hands-on learning is the best way to teach and bring life to STEM-related (Science, Technology, Engineering and Manufacturing) curricula. In recent camp programs, participants performed hands-on activities like designing electronic devices, learning how to weld, building robotic arms and more. Janler Corp. is one of several companies that have opened their doors to the “campers,” as Sharris calls them, to further expose them to a variety of manufacturing environments and career options.

Girls on Tour

It was a warm, sunny summer day when Lake Park’s Smith and Triton’s Sharris arrived at Janler with their group of very curious young ladies. Joining them were Renee Nehls, a tooling engineer, former mold designer, and then Chair of the SPE Mold Technologies Division, and Dan Kuch, area account manager, Midwest, at Hasco America, to lend additional perspectives. “Hasco has been a partner and contributor to youth education and information about the plastic industry,” Klingler says. “Dan offered to assist us and speak to these students, and we gladly accepted his participation. Renee is very actively involved with youth and is passionate about female participation in manufacturing. She speaks with authority and from the heart. You feel her intensity and you believe her message.” MoldMaking Technology was also on hand to cover the event.

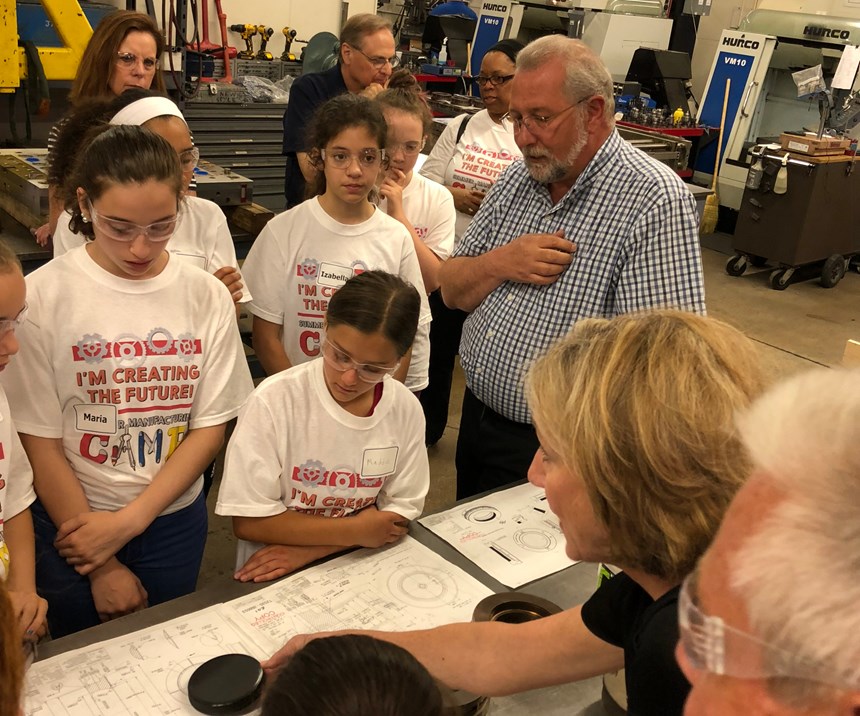

Both Ebel and Klingler greeted the girls outside the front entrance to the Janler plant, providing an overview of what they were about to experience. As expected, none of the girls knew what moldmaking was, but they were excited to see and learn about it. The GADgET Girls toured every department of Janler Corp., from the engineering department to EDM to CNC machining and production.

There isn’t enough making going on with our youth.

“Their eyes were wide open, and they had many good questions and comments that confirmed they were engaged,” Klingler says, explaining how interested they were to see how molds are designed in 3D on a computer. When they saw blueprints and actual molds and could match the molded product to the prints and mold cores, they further understood how everything comes together. Sharris adds, “They became aware of how things are made. We don’t have enough education on this front. They were not focused on moldmaking, but simply on making. There isn’t enough making going on with our youth.”

The Janler team made sure to provide examples of mold cavities and cores for products the girls recognized, like plastic containers and lids for candy, nuts and peanut butter-filled pretzels they buy at warehouse stores, and threaded caps for bottles—even tubes for lipsticks. The girls observed as plastic parts were molded, inspected and boxed, learning about that process from Alan Klingler, vice president. “We think it really starts in the molding and production of plastic parts. Everyone can see a component, and understand where and how it may be used, but then to see the moldmaking process that is needed to produce an injection mold so that component can be manufactured really opens their eyes.

“The size and speed of the molds and molding machines fascinated these young girls,” Klingler adds. “I think they were also intrigued by the technology that is used in moldmaking, and by seeing several young people working in our shop as machinists and moldmakers.”

Sharris says she knows the girls were impressed by what they saw at Janler, but she wants to see these experiences go deeper. “I think it is tough to show the mold industry to youth because it is all ‘hidden’ activity (inside the machine). I would like to see companies offer some hands-on time with a safe project that allows the youth to engage with the making process,” she says.

Girl to Girl

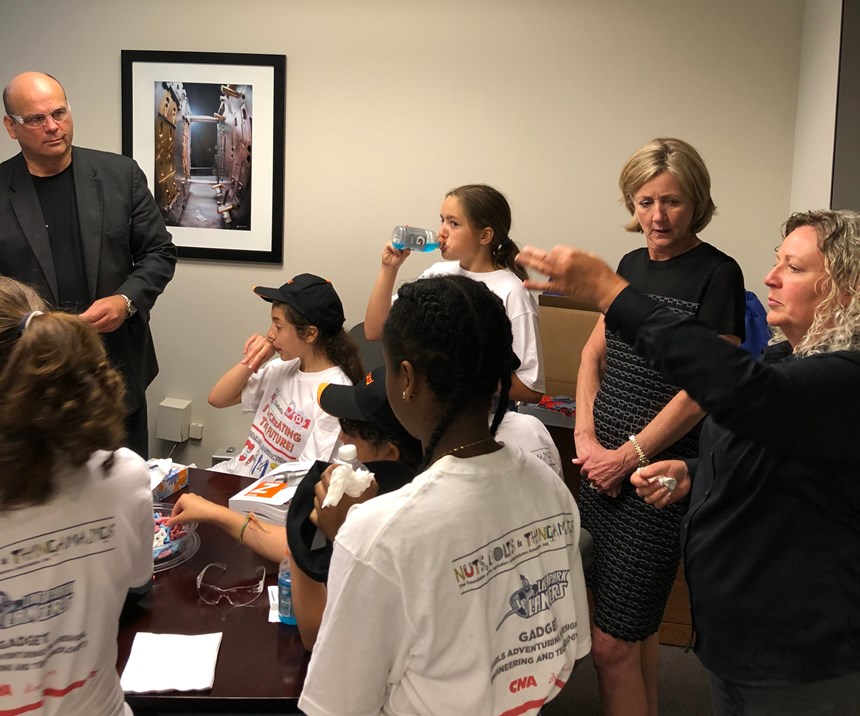

At the conclusion of the tour the girls were offered refreshments and bags with goodies to remember their experience. They gathered around a conference table where Hasco America’s Kuch let them hold and pass around a variety of mold components and learn how they are used. Nehls described her experience as a woman mold designer. “I told them that working in moldmaking is a unique opportunity if you are able to visualize in 3D,” she says. “If you enjoy the mechanical sides of things, where part A interacts with part B, which activates part C, and that is logical for you and you enjoy working on computers then this is a viable vocation. Running 3D software requires an understanding of the way software thinks if you are going to capitalize on its capabilities.”

It’s important to understand the impact it can have, meeting someone like Carol, or myself, who has been in the trenches.

Nehls points out something that Carol Ebel said to the girls that she felt was very powerful. “She was talking about problem solving and that skill being a key attribute for moldmaking. She really hit on something very important when she said that,” Nehls says, adding that it was such a benefit for the girls that they were able to see and interact with Ebel, a woman who has received several awards for her dedication to the industry and who has accomplished so much leading Janler Corp. “It’s important to understand the impact it can have, meeting someone like Carol, or myself, who has been in the trenches.”

Measuring the Impact

“Janler did a great job of relating to the students in an age appropriate way, too,” Nehls says. “They didn’t talk down to them and they didn’t talk overly technically, which is so important because this was their first exposure to what a mold is and what it does.” She says both Klingler and Ebel are clearly passionate about moldmaking and sharing their love of the industry with all students. “It was a very good tour and I would join them again if they asked me to.”

We got to see how molds are made and how you create an idea on the computer and then make it out of metal.

As it happens, Janler continues to work with local schools and hosted a tour for Lake County College not long after this feature was written. Asked about the feedback Janler received from Lake Park High School and Camp GADgET, Klingler says he received a note from Ian Smith that said, “Thank you so much! The students were very amazed and appreciative of everything they saw. They continued to comment on it throughout the day… Janler was mentioned, as well as the things they learned while there, over and over again. I think the impact on them was bigger than we know.”

At the conclusion of each Camp GADgET experience, the young ladies are asked to create a PowerPoint presentation in which they present the product that they designed and created over the course of the two weeks. They share what inspired them to make the product, the design and prototype, materials used (including costs), equipment used and the product itself. On the final slide, they sum up their Camp GADgET experiences.

Nicole, a camper who has participated in the GADgET Girls program before, posted in her presentation that “going to Janler was fun. We got to see how molds are made and how you create an idea on the computer and then make it out of metal. They make plastic cup caps and watching them being made was cool.”

A fellow camper, Emma, said the following in her presentation: “I have also seen how molds are created at Janler and how the people there are always working hard and coming up with new machines.”

Janler gave the girls real examples that they can relate to, not widgets.

Sharris says, “Overall, most youths under age 18 are not even allowed in such a place, so simply seeing a production facility is a new thing for them. This was such an eye-opening experience to have the girls see the inside cavities they showed at the facility and show the products (the lipstick tubes were a standout). Janler gave the girls real examples that they can relate to, not widgets. This is important so the girls can relate what the facility makes to what they see at home.”

In her thank you note to Janler, Sharris said, “Thank you for bringing in so many people to speak with them, for the hands-on explanations and demonstrations of the manufacturing process, and for all the goodies! I've visited many companies with student groups, but today's visit tops them all.”

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreEden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreRead Next

Creating Moldmakers by Offering Training and Cultivating Passion

Several mold manufacturing companies have shared how their workforce development strategies have evolved to meet the needs of today’s industry. Here, Janler Corp. outlines its approach to workforce development, which is largely about seeking and cultivating passion and motivation in new recruits.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More