The MMT team kept busy in March with PTXPO and the celebration of our 25th Anniversary. We also managed to fit in content covering our readers’ favorite topics such as digitalization in tooling, mold life cycle management, hot runners, cold runners and much more. Take a look at the list below and see what sparks your interest.

10. 25 Years Later and Molds Still Make a Difference

I believe 25 years proves that moldmaking matters! So, what better time than now to promote what you shared with me last year after I posed the question: “We say molds make a difference; what do you say?”

9. Leadtime Leader Award Winners: Hall of Fame

MoldMaking Technology’s Leadtime Leader Competition has been an ongoing award since 2003. It is a prestigious award given only to North American mold builders that go above and beyond in moldmaking. Honorees have expressed the value the Award has afforded them in exposure, recognition, morale and new business.

8. Celebrating the Importance and Impact of the Moldmaking Community

The moldmaking community often comes together outside of work to give, honor and celebrate. Here are just a few examples.

7. What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

6. MMT Chats: Key Pain Points and Leverage Areas of Advanced Tooling

Editorial Director Christina Fuges chats with Dr. Ahmed Arabi Hassen, R&D Staff Scientist, Oak Ridge National Laboratory, about advanced tooling research and development. This episode is brought to you by ISCAR.

5. MMT Chats: Why Is Tooling Digitalization on the Rise?

MoldMaking Technology Editorial Director Christina Fuges chats with Bob Vancoillie with the Consumer Division of Johnson & Johnson about OEM corporate initiatives for digitizing tooling. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

4. MoldMaking Technology Magazine Turns 25 Years Old

This year marks the 25th anniversary of MoldMaking Technology magazine!

3. How to Transition From a Cold to Hot Runner Mold

Reducing cycle time and costs while also freeing up your machines for other projects are advantages gained by using hot runners that no one can ignore. But where does one begin transitioning from cold to hot runners?

2. MMT Chats: Project Reveals Added Benefits of New P20 Grade Steel in Machinability, Cycle Time and No Stress Relief

MoldMaking Technology Editorial Director Christina Fuges chats with Shane Appel, Polymer Manufacturing Engineer with General Motors about a project conducted with Omega Tool and Finkl Steel to prove the dimensional stability of a new grade of P20 steel. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

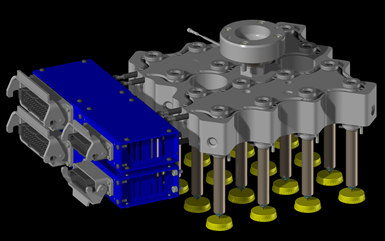

1. Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Photo Credit: General Motors Co.

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Related Content

Patrick Roussey II Named 2023 Mold Maker of the Year

The SPE Mold Technologies Division awarded the Mayer Tool & Engineering moldmaker recipient for his lifelong commitment and contribution to the moldmaking and plastics industry.

Read MoreTool Paths, ERP & Improving Efficiency in Your Toolroom: What Did You Miss in February?

We covered a variety of topics in February. From tool paths to ERP and PTXPO coverage, we hope you didn’t miss anything but here is your cheat sheet if you did.

Read MorePTXPO Preview 2023: Upcoming Software/Simulation Services, Training and Marketing Solutions

This latest installment of PTXPO snapshots feature companies in and around the Moldmaking Pavilion powered by Amerimold that provide industry solutions in software, simulation, training and marketing.

Read MoreSPE Mold Technologies Division Presents Moldmaking Award Winners

At PTXPO, the 2023 Mold Designer of the Year, Mold Maker of the Year and Mold Repair Technician of the Year were awarded to Chuck Heitmeyer, Pat Roussey II and John Demakis Sr., respectively.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More