Roughing and Finishing on One Highly Accurate Machine

Precision mold builder finds machine tool with versatility, large work envelope, excellent finishing capabilities, and enough horsepower to take on roughing jobs.

We’ve covered L&Z Tool and Engineering in the past, so when this application story came across my inbox I just had to share:

In late 2020, Luke LaMarca, VP of Technical Operations at L&Z Tool and Engineering, Inc., realized his shop needed an upgrade to keep up with the competition. His aging horizontal machine had a small work envelope and couldn't be equipped with a rotary table, limiting the jobs L&Z Tool could accept.

"We would have to turn away some jobs because they were too large for that machine," LaMarca says. "We're trying to keep up with the advances in technology, which means keeping our CNC equipment up to date."

The leadership at L&Z Tool, which includes LaMarca and his two brothers, knows what it takes to succeed. Luke LaMarca's grandfather and part of the namesake for L&Z Tool, Tom LaMarca Sr., emigrated from Italy and eventually mortgaged his home to start L&Z Tool in 1952. Luke LaMarca's father, Tom LaMarca Jr., began working at the shop from a young age and is still a critical part of the company. During that time, he's learned some valuable lessons.

"The key to staying competitive is to advance with technology continually," Tom LaMarca Jr. says. "Bringing in high-end machines has been one of the reasons we've stayed in business for almost 70 years."

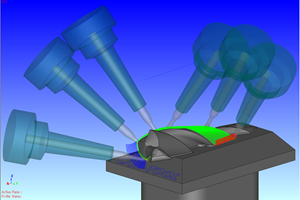

With that mindset and company culture, Luke LaMarca set out on finding a new machine tool. L&Z Tool is well-versed in the benefits of simultaneous five-axis machining, namely the ability to maneuver molds and cut small, intricate paths. LaMarca wanted similar versatility in a new horizontal machine. However, he also needed a machine with a large work envelope, excellent finishing capabilities, and enough horsepower to take on roughing jobs.

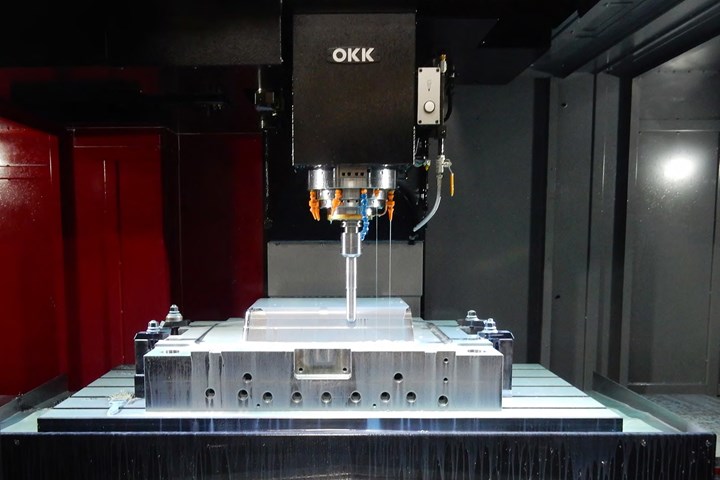

The OKK HM1000s provides four-axis simultaneous cutting, an expansive work area, and a spindle with high rpms backed by 60 horsepower.

Accurate Solution

The search didn't last long. All LaMarca had to do was connect with his longtime machine tool supplier Nick Giannotte, currently the Director of Sales Operations at Maruka USA. The two have been working together for close to 30 years. Simply put, LaMarca says that Giannotte and Maruka Sales Engineer Kevin Ducey presented the best machine to meet L&Z Tool's needs and the best deal—the OKK HM1000s.

The HM1000s provided four-axis simultaneous cutting, an expansive work area, and a spindle with high rpms backed by 60 horsepower. And as with most horizontals, the machine tool came with a PC2 pallet changer to increase their unattended runtime. It was easy for LaMarca to see the benefits of four-axis simultaneous cutting.

"It gives us the ability to reduce our setups and get into some tighter spots," he says.

Making small, high-tolerance cuts enabled the company to ease off EDM, a more time-consuming process. Additionally, the versatility of the HM1000s permitted the shop to rough and finish a mold on a single machine, forgoing the need to run multiple machines to complete one job. The spindle can run at 12,000 rpms, allowing the use of smaller end mills, while the high horsepower enables the machine to remove significant amounts of material during roughing.

"The accuracy on these machines are very good, too," LaMarca adds.

Later in the year, LaMarca considered a vertical machine after another piece of existing hardware started to show its age. Initially, he had his sights set on a machine tool with a CAT50 spindle. However, he opted for an OKK VM76R with a CAT40 OKK VM76R after learning about the spindle's dual-contact capabilities. The dual-contact spindle provided better surface finishes and dimensional accuracy.

The OKK VM76R with a CAT40 OKK VM76R dual-contact spindle provides better surface finishes and dimensional accuracy.

"It actually helped with another project that was flowing through here at the time, and we were able to get very nice finishes off it," he said.

LaMarca opted for numerous auxiliary options with each machine. The HM1000s came with probing and laser-measuring system, unique options that gave operators the capacity to obtain more accurate measurements. The VM76R came with access to a data server, which enabled programs to be uploaded faster, saving valuable time.

"The older machine was definitely not equipped to do that," LaMarca notes. "Our jobs require extremely stable conditions and highly accurate machines. OKK delivers on both those qualities.”

Related Content

Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreHow to Generate the Ideal Tool Path for High-Level Accuracy and Finish

When a mold builder can’t compromise part accuracy and surface finish, CAM software with specialized programming strategies is essential.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More