Purchasing Considerations for Standard Slide Assemblies

Mold manufacturers must consider several factors when evaluating standard components—quality, cost, design benefits and features, and their effects on the finished tool.

Standard slide assemblies have been available to molders and moldmakers since 1991. The design and production of a standard component is critical to the success of the product. Not only does the design have to be very reliable and proven, it also has to be versatile enough to fit many different applications. That is the true benefit of using a standard component.

The moldmaker can buy a high quality standard slide unit with a proven design off-the-shelf and have it delivered in a few days. Slide assemblies have many different design benefits and features. The slide manufacturer has to be very careful when deciding which of these to include in the design of the product. Too many features added to a standard product, can end up hurting the true intent of the component.

Standard components need to have the basic benefits and features that can be used by a majority of the industry. Once you start adding too many features to the design, it is no longer viable to the majority of the users.

Some features on standard slides may seem appropriate at first glance, but upon closer examination could result in an over-engineered component. Many features and modifications can always be added by the mold manufacturer to fit his application. Remember that it is more difficult to remove a feature that is unnecessary than to add one.

For example, grease grooves—which for some applications are good features—can cause potential issues when the slide is being used in a mold that cannot have any grease used. If an operator sees grease grooves he is bound to add grease to that part and then the molding process could be ruined for the entire run of parts.

Main Considerations

In critical alignment areas the design must allow an accurate and consistent alignment of the two critical parts, and also allow for ease of assembly. In a standard slide assembly there are two critical alignment areas to consider. The first is where the guides meet the wear plate. Traditional means of achieving this alignment was to use dowels, which works fine but requires secondary operations to achieve the alignment at assembly—at the bench with a wire operation, line reaming or some other technique.

An alternative method is the use of a finish ground tongue and groove slot for alignment of the guides, which achieves a maximum amount of rigidity and accuracy without any secondary operation needed by the moldmaker—saving time and labor costs. The second area of critical alignment is from the slide body to the slide face. Again, traditional means uses dowels or you can use a tongue and groove design.

Another factor to consider here is the cost of the standard component. A standard component is easier and less expensive to produce with a dowel method of alignment because it does not require extra mill and finish grind operations to produce a tongue and groove, which should translate into a less expensive finish assembly product for the customer. However, the customer has to incur the cost of the secondary operations necessary to achieve the critical alignment at the bench. So consider both the cost of the component and the cost of installation when purchasing.

Benefits of a Clean Design

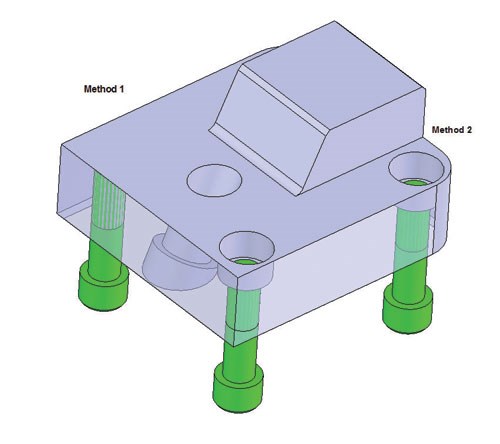

A clean design that can be adapted by the customer to use in his particular mold situation is essential. So when choosing a standard component, make sure any added features do not hinder the benefit of using the component in the first place (see Figure 1). For example, let’s look at installing the wedge into the A-side of a tool.

There are two preferred methods. One is to attach the wedge from the back side with assembly screws that come through the top clamp plate and into tapped holes in the back of the wedge. This method allows for a more secure attachment of the wedge and leaves the parting line of the tool as free of geometry as possible.

The other method is to attach the wedge from the face, which allows for much easier assembly for the moldmaker, and is usually used in less critical tools. If a standard wedge has options for both of these methods of assembly, it adds to the features of the component, but can detract from the overall benefit of using a standard component.

To illustrate consider a moldmaker who is working on a class 101 mold and attaches the wedge from the back side with assembly screws. If the standard component has options for both methods of assembly, it requires a counter bore for the screw that would be used to attach the wedge from the face. This leaves open counter bores at the parting line of the tool that are not being used, which can allow dust and debris to accumulate at the parting line.

Summary

Moldmakers need to consider many different factors when evaluating standard components. Quality and cost of the component are usually the first considerations, but the moldmaker should also consider the benefits and features of the component’s design, and how it will affect the quality and function of the finished tool.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Standardized Mold Building Makes Shortened Leadtimes Possible and Profitable

The next level of standardization has allowed moldmakers to rethink their processes and deliver the same high-quality molds, while continuing to succeed and grow.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More