Moldmaking Index Ends Quarter Holding Gains

Production and employment lift index, at 53.5 for September

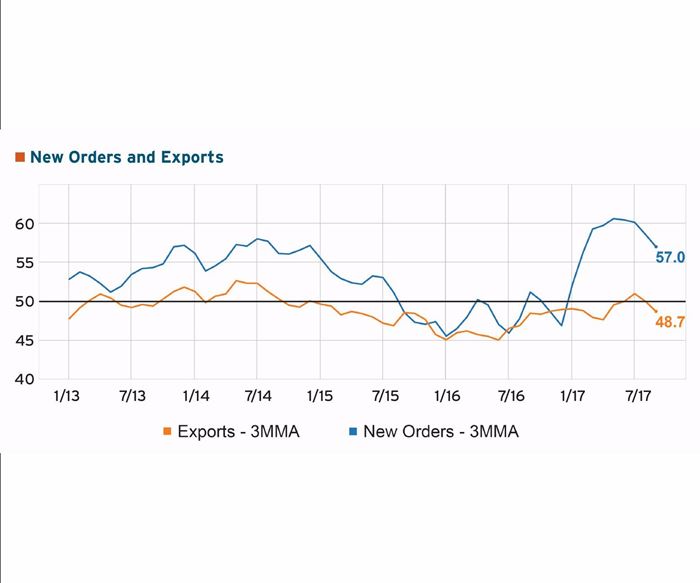

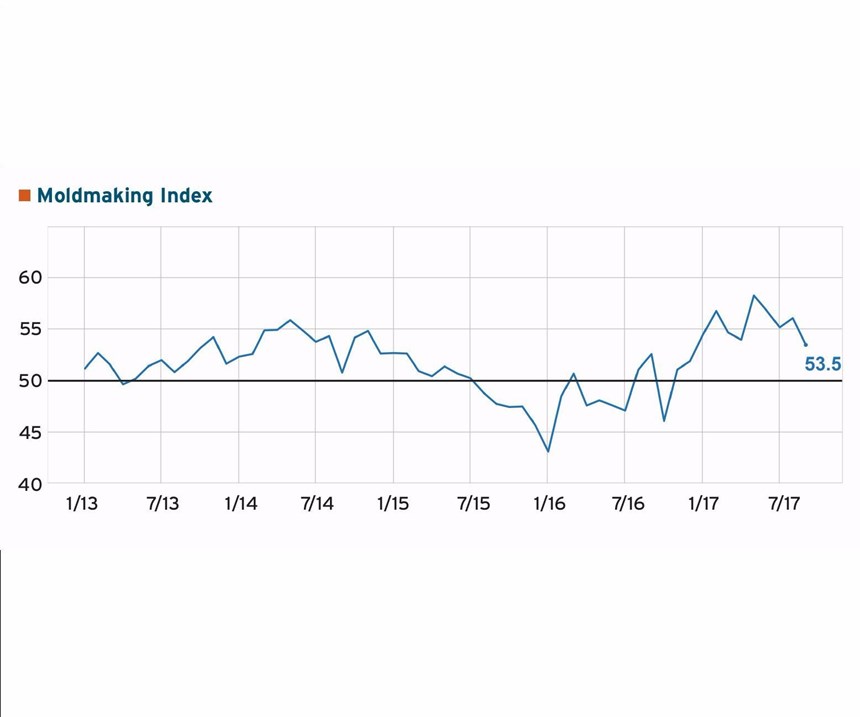

Registering 53.5 for September, the Gardner Business Index (GBI): Moldmaking fell slightly as it ended the third quarter of 2017. This latest reading brought the 2017 year-to-date index average to 55.5 and the third quarter average to 54.9. For the year-to-date and 12-month periods, the index changed approximately -2 percent and 2 percent, respectively. Gardner Intelligence’s review of the underlying data for the month indicates that supplier deliveries, production, employment and new orders lifted the Moldmaking Index higher while backlog and exports pulled the Moldmaking Index lower. The decline in the Moldmaking Index for this month was largely a result of slowing growth in new orders and backlog combined with a contraction in exports that had posted growth during the previous month.

The Moldmaking Index results among custom processors alone during 2017 have been marginal compared to the broader Moldmaking Index. Results during the third quarter indicated slowing growth for both groups. More information about the Moldmaking Index can

be found at gardnerintelligence.com.

About the Author

Michael Guckes

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

-

Editorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

.jpg;width=70;height=70;mode=crop)