GBI: Moldmaking August 2017 – 56.1

The growth in the moldmaking industry is accelerating.

The GBI: Moldmaking Index increased slightly for August 2017, registering at 56.1. Through the year-to-date period, the Moldmaking Index has trended upward since it contracted during the fourth quarter of 2016. The upward trend of The Moldmaking Index indicates that the growth of the moldmaking industry has been accelerating generally throughout the current calendar year. Readings in supplier deliveries, new orders, production and employment bolstered The Moldmaking Index while backlog and exports pulled it down.

The slowing rate of growth in production and new orders continued for a third consecutive month after having accelerated rapidly during the first quarter of 2017. When production and new orders move closely together, there is typically only minor volatility in backlogs. Production and new orders have generally moved in a parallel direction during 2017, and changes in exports have been relatively unchanged. Backlog in the year-to-date period through August has experienced relatively modest growth with the average for the year at 54.2. The Gardner Intelligence team closely monitors backlog, as it is often thought to be a bellwether of capacity utilization and machine tool sales.

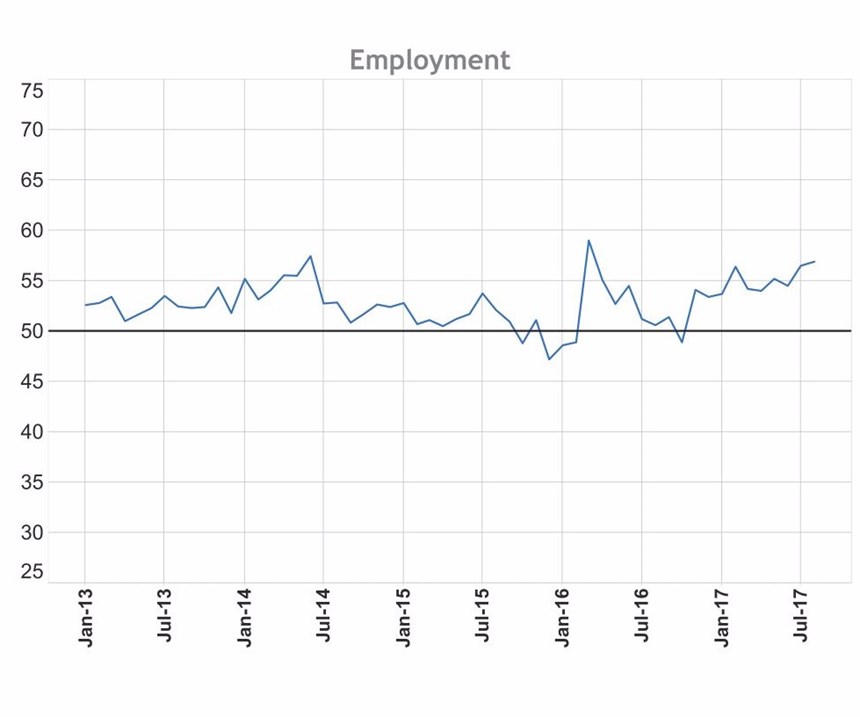

The strength of The Moldmaking Index employment metric indicates that employment growth in 2017 is the strongest that it has been in the moldmaking industry since at least 2013.

The exports reading for August indicated expansion for the second time in 2017. During the year-to-date period, the average export reading of 49.3 indicates that exports have been slowly shrinking. This has been happening even though the value of the U.S. dollar has been falling by nearly 8 percent against other major currencies since the beginning of the year.

The U.S. economy has seen overall improvement and growth. As a part of this general improvement, employment data has recently shifted. Greater attention has been given to this shift because the numbers have moved uneventfully for the past two years. During the first two quarters of 2017, manufacturing employment metrics jumped significantly, and only recently has the growth in employment shown any signs of moderating. This, however, has not been the case in the Moldmaking Index data, as employment metrics in August signaled the fastest growth in employment for 2017. The strength of The Moldmaking Index employment metric, averaging 55.7 year-to-date, indicates that employment growth in 2017 is the strongest that it has been in the moldmaking industry since at least 2013.

The August results from custom processors alone also indicated improvement from the prior month. For the month of August, supplier deliveries drove much of industry improvement that custom processors alone reported, with production and new orders playing only modest roles in the improvement of the business environment.

Related Content

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

Top 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

.jpg;width=70;height=70;mode=crop)