Moldmaking Index Contraction Nearly Stops in December

The Moldmaking Index closed out 2019 slightly below a reading of 50.

The Gardner Business Index (GBI): Moldmaking was nearly unchanged in December after reporting its sharpest contraction in nearly 4 years during November. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50, the greater the magnitude of change in business activity. December’s improved reading came as a result of expansionary readings for new orders, production and backlog. The Index — calculated as an average of six components — was pulled lower by employment, exports and supplier deliveries. Only the reading for supplier deliveries moved lower in December.

The Moldmaking Index closed out 2019 slightly below a reading of 50. Five of the six components of the Index experienced improved readings during December. Three of the six components reported expanding activity.

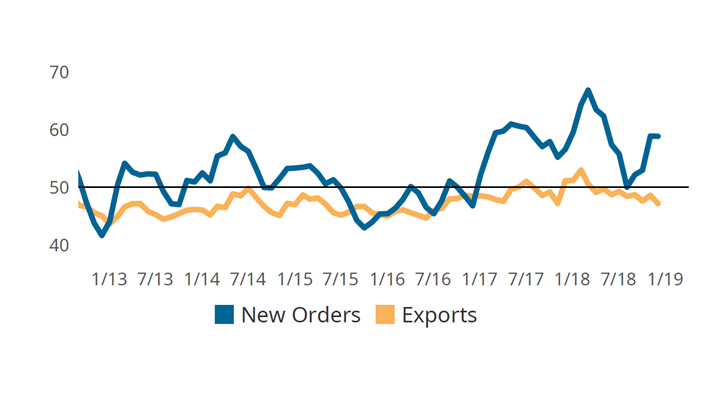

During the second half of 2019, monthly new orders and production readings oscillated above and below the 50 line, which divides expanding from contracting business activity. The lack of a trend here, coupled with an accelerating contraction in backlogs and exports, placed further pressure on the Index. December’s data, however, was notable for several reasons. The reading for backlog activity expanded for the first time since April. This was in part due to expanding total new orders and a slowing contracting in export activity. Excluding supplier delivery activity, all components of the Index registered higher activity readings in December than during the prior month.

Slowing and contracting new orders and exports in 2018 and 2019 facilitated a simultaneous contraction in backlog activity. December’s backlog reading was the first expansionary backlog reading since April and the first to drive the Index higher since February of 2018.

Related Content

-

Moldmaking Sector Sees Future Optimism Despite Current Challenges Subhead

Strong future expectations signal potential rebound as automotive and medical sectors prepare for growth.

-

Moldmaking Activity Begins 2024 With Slowed Contraction

January index reading reflects February-March 2023 readings as it slinks toward a reading of 50. There are high hopes that it may continue on this path to sustained expansion for 2024.

-

Moldmaking GBI Returns to Contraction After One-Month Respite

After a challenging move into the 50s in March, the April GBI returned to a mostly consistent state of contraction, the result of recent market dynamics.

.jpg;width=70;height=70;mode=crop)