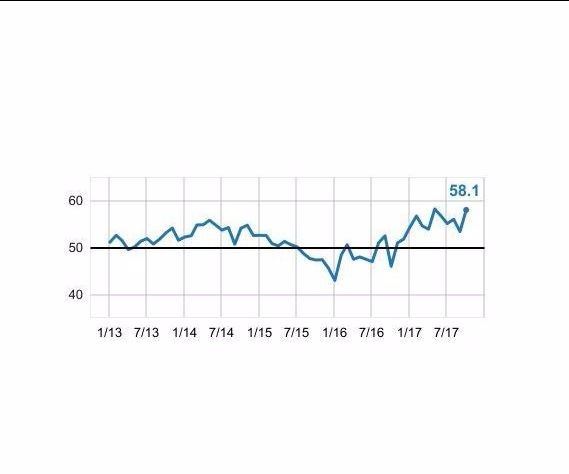

Moldmaking Index Continues to Show Solid Growth in 2017

October 2017—58.1

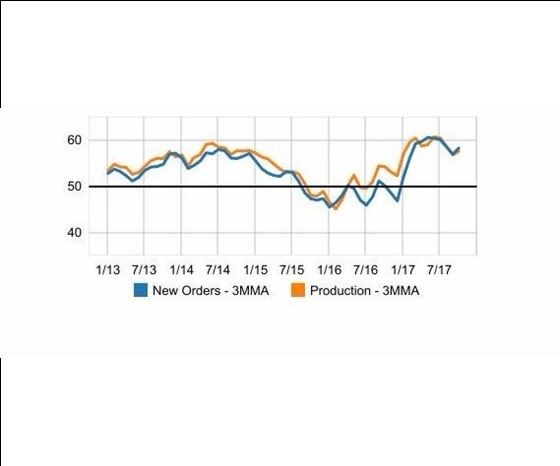

Registering 58.1 for October, the Gardner Business Index (GBI): Moldmaking increased significantly from its point at the end of the third quarter of 2017. Over the last five years, this month’s reading is second only to the record reading that occurred in May 2017. This latest reading brings the 2017 year-to-date Moldmaking Index average to 55.8. For the year-to-date and 12-month periods, the Moldmaking Index changed approximately 6.4 percent and 23 percent, respectively. These changes are significantly different from those reported in September because of a very weak October 2016 reading and a very strong reading in the current month. Gardner Intelligence’s review of the underlying data for the month indicates that new orders, production and supplier deliveries lifted the Moldmaking Index higher, while employment, backlog and exports pulled the Moldmaking Index lower. For the month, no components of the Moldmaking Index contracted. For more information on the Moldmaking Index, visit gardnerintelligence.com.

About the Author

Michael Guckes

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

Steps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

.jpg;width=70;height=70;mode=crop)