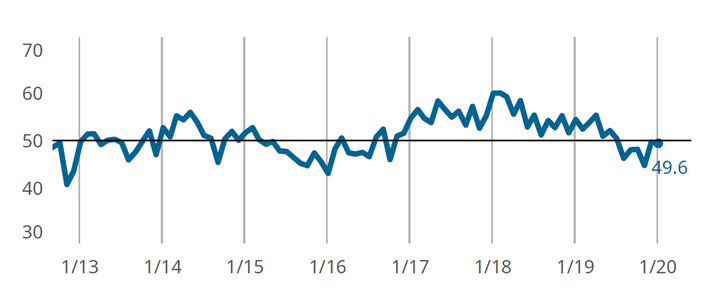

Moldmaking Business Activity Generally Unchanged for Second Month

January’s moldmaking index reading being so near to 50 indicates that business activity was little changed for a second consecutive month.

The Gardner Business Index (GBI): Moldmaking moved only slightly in January with a 20-basis point decline to 49.6. Index readings above 50 indicate expanding activity while values below 50 indicate contracting activity. The further away a reading is from 50 the greater the magnitude of change in business activity. January’s reading being so near to 50 indicates that business activity was little changed for a second consecutive month. Despite the slight decrease in the total Index, survey participants indicated expanding activity in new orders and production. The Index -calculated as an average of six components- was pulled lower by supplier deliveries, employment, exports and backlogs.

The Moldmaking Index started 2020 with little change from December’s reading. All components of the Index have moved off their 2019 low readings.

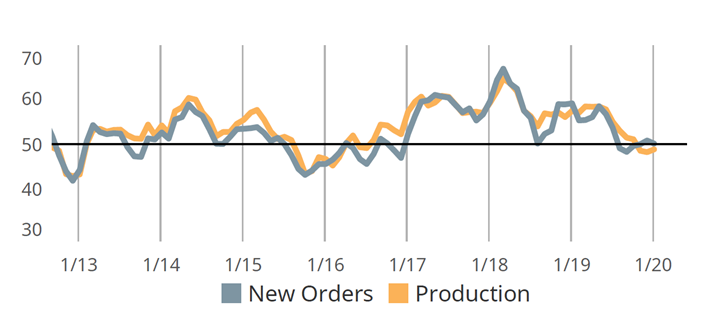

Production and new orders both extended their expansionary gains from the prior month. In both periods, production readings reported slight greater expansion relative to new orders. This variance may in part explain January’s contractionary backlog reading after survey participants reported expanding backlogs in December. A directional change in new orders activity often precedes corresponding changes in other components including production, backlogs, supplier deliveries and employment.

January’s expansionary new orders reading, which measures total new orders activity, came despite a quickening contraction in exports. The combination of these events implies that an improvement in domestic orders activity more than offset weakening exports.

New orders and production activity expanded for a second consecutive month in January. A directional change in new orders activity often precedes corresponding changes in other components including production, backlogs, supplier deliveries and employment.

Related Content

-

Moldmaking Industry GBI Contracts for Four Months Straight

The GBI Moldmaking ended the month at 45.8, down one point from June, with components contracting or nearing contraction activity.

-

Moldmaking Sector Sees Future Optimism Despite Current Challenges Subhead

Strong future expectations signal potential rebound as automotive and medical sectors prepare for growth.

-

Moldmaking Accelerated Contraction in June

June’s moldmaking index took a relatively steep downward turn, landing at a new low for the year.

.jpg;width=70;height=70;mode=crop)