Mold Base Tooling Improved with Stainless Holder Steel Development

In the early 1980s, leading mold base manufacturing companies challenged the specialty steel suppliers to develop an improved pre-hardened stainless holder steel for use in mold base tooling.

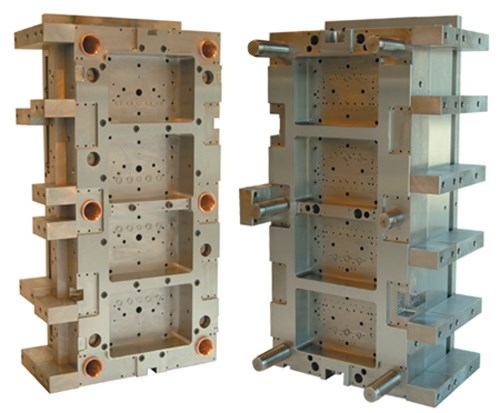

In the early 1980s, leading mold base manufacturing companies challenged the specialty steel suppliers to develop an improved pre-hardened stainless holder steel for use in mold base tooling. Working in cooperation with several European-based steel producers, the first heats of pre-hardened stainless holder steel, specifically for the mold base application, were produced. These grades were modified pre-hardened high carbon 420-type stainless steels, which had many similarities to the 420 ESR (DIN 1.2083) insert quality materials already widely used in the market, for cores and cavities, with the addition of sulfur and other elements for improved machinability. These so-called 420F steels, such as DIN 1.2085 and DIN 1.2316, would become a standard for multi-cavity plastic mold base tooling for the next 15 years.

While these 420F materials succeeded in improving on the negative aspects of using 420 ESR (DIN 1.2083) for mold base plates, complaints persisted concerning the 420F type stainless steels—including inconsistent and unpredictable dimensional stability, brittleness and low toughness, material break-out and cracking, inconsistent hardness and unreliable weldability.

For years, the team at Edro Engineering’s custom mold base production center in California had experienced these same problems first hand, while building stainless mold bases for the North American market. Although Edro had been influential in the development of the 420F type stainless materials in the early-1980s, they realized that these 420F materials were still not ideally suited for mold base applications.

Answering an Industry Need

In 1992, Edro began its own internal R&D program to develop a superior stainless mold base steel. Following several years of material trials, and extensive metallurgical and machining tests, Edro found that a low-carbon stainless composition would be better suited to handle the demanding manufacturing and production requirements of plastic mold base tooling.

Bob Friedrich, Technical Manager at Edro explains, “We found that this significant compositional difference would lead to advantages in terms of our mill production, and the manufacturing processes used to produce and run high-volume mold base tooling, while retaining the corrosion resistance necessary for this demanding application.”

In 1997, Edro introduced and patented RoyAlloy™, a pre-hardened, low-carbon, free machining 400 series stainless steel, which was developed specifically for plastics mold base tooling.

Industry Feedback

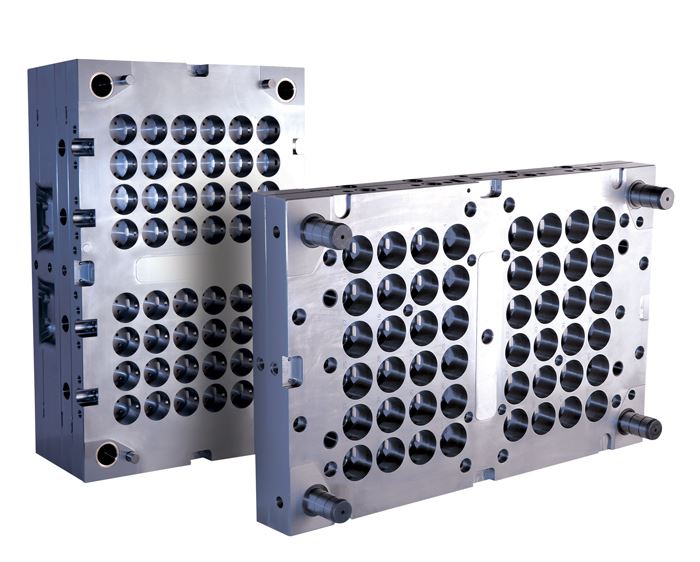

Mike Guscott, Vice President of Sales at Edro Specialty Steels recalls, “The first real sign of a large market potential for this new material came when Don Miller and Ray Evans from Calmar Corporation approved the use of RoyAlloy for the mold base plates of a large multi-mold program.” Edro agreed to build six mold bases for Calmar, half would be built from their new material RoyAlloy, and the other half would be built from the standard 420F (1.2085) material popular at that time. After one year in production, a detailed inspection was conducted on the mold base plates from each type of material. Calmar found that the mold base plates built from 420F (1.2085) demonstrated distortion in all directions, while the RoyAlloy plates had remained much more dimensionally stable. Calmar realized that over time this would lead to less cavity wear and better mold performance, as well as retain the interchangeability of the mold plates. At that time, Calmar decided to change their mold base material standard to specify RoyAlloy.

As Edro expanded RoyAlloy across the country, moldmakers and molders quickly recognized its benefits. Scott McWilliam, President of Ivanhoe Tool & Die explains, “We changed from the traditional 420F grades to RoyAlloy for all our stainless mold base plates because of its superior machinability. It also provides a more consistent and uniform product with improved dimensional stability and surface finishes compared to the 420F type materials.”

Brian Flynn, Managing Director of Operations at Marland Mold adds his thoughts, “RoyAlloy™ has proven to be the most consistent stainless mold base steel, providing us with predictable cutting tool life, and leading to a measurable reduction in our expendable tooling costs.” While J.D. Faulkner, Vice President Operations at F & S Tool describes, “Six years ago, we changed completely to RoyAlloy™ Stainless to replace a series of cracked 420F stripper plates. Its improved mechanical properties and toughness have eliminated our recurring failures.”

A New Direction for Stainless Holder

Over the next decade, the global demand for this type of low-carbon pre-hardened stainless mold base material increased quickly. Moldmakers and molders realized they no longer had to sacrifice machining time, cutting tool life, plate stability and mold interchangeability in order to use a stainless steel for their mold bases. Bill Kushmaul, President of Tech Mold explains, “RoyAlloy™ plates provide us with improved dimensional stability and mechanical properties compared with the standard 420F materials, enhancing our pursuit to provide the highest quality molds to the plastics tooling industry.”

Mike Guscott concludes, “The message from the market is clear, low-carbon stainless holder grades offer significant advantages compared with all previous high-carbon 420F type materials.”

Related Content

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMaking Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More