MGS Mfg. Group: Sampling Success

A foray into sampling led this toolmaker to design its own multi-shot tooling system and equipment.

|

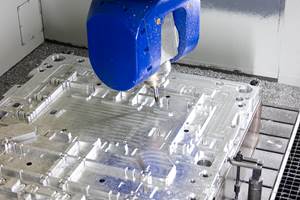

When first profiled by MoldMaking Technology in May, 1999, Germantown, WI-based MGS Mfg. Group’s primary revenue-generating activity was toolmaking. The past 10 years have seen an explosion for the company as it experienced a significant phase of growth and change—developing into a full-service “engineered solutions” provider of design, tooling, sampling, mold and part qualification, production molding, automation and turnkey manufacturing systems. Much of this growth can be attributed to MGS Group’s oldest member company Moldmakers Inc. “This tool shop is an engineering beast,” notes MGS Group Marketing Director John Berg. “At more than 60,000 square feet, it features all of the traditional equipment you’d expect from a large, modern shop (wet/dry surface grinders, horizontal/vertical machine centers, CNC lathes, jig grinder, etc.) along with a deep staff of personnel (60+ journeyman toolmakers/CNC techs/EDM techs, 20+ designers/engineers, 20+ program managers), plus extensive automation capabilities. The automated tool shop features three high speed/high precision hardened steel machining centers with integrated robotics and CMM, three high speed/high precision graphite machining centers with integrated robotics and two CMMs, three dual machine sinker EDM cells with integrated robotics, and the ‘Monster’ cell—six wire EDMs with two CMMs and a rail-mounted, six-axis robot to feed it.”

A Turning Point“One of the most significant events in the history of our company occurred in the late ‘90s when we created our first portable injection units to sample the multishot molds we were building,” recalls Berg. “The success of our ‘sampling’ units led to the development of full featured production models. The MGS line of Universal Multishot Systems (UMS) includes vertically and horizontally mounted injection units that convert a standard injection molding machine into a multishot press. Other UMS equipment includes Rotary Platens and Vacuum Units. The success of our UMS line has facilitated our growth as a leading provider of multishot tooling systems and equipment. MGS toolmakers also took a lead role in developing MGS Automation Systems, Berg notes, which are custom equipment solutions provider for the downstream events associated with production molding, like assemblies, decorating, degating and packaging.

Developing and AcquiringBerg predicts the company will continue to grow by investing in the development of new technologies to improve manufacturing efficiencies in the following areas: in-mold assembly, multishot development for medical products, water injection technologies, and automating value-added operations. The company also recently developed and acquired several companies to strengthen its position in the marketplace. PMD (Prototypes, Molds, & Design) was developed as a company-within-a-company dedicated to time-to-market deliveries of tooling systems. “PMD is staffed to operate in a leaner environment,” Berg stresses. “It is equipped with the required machinery, but with a smaller staff. PMD does not house the automation capabilities of Moldmakers, Inc., and as a result, has a lower overhead structure, allowing PMD to be more competitive with customers not requiring the full engineering horsepower of MGS.” In 2006, MGS acquired All West Plastics, an ISO Class 8 cleanroom/white room molding operation. Its most recent acquisition is Sousa Plastics in Chihuahua, Mexico. “This facility is now called TecStar de Mexico and serves a variety of markets (electronics, automotive, appliance),” Berg notes. “We will continue to look for strategic expansion opportunities in the next 10 years.”

|

|

Related Content

How to Achieve Unmatched Accuracy in Very Large Workpieces

Dynamic Tool Corp. purchases two bridge-style double-column CNCs to increase the cutting envelope and maintain 5-micron cutting accuracy in the long term.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreTrue Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreRead Next

Magor Mold: 40 Years and Counting

Alliances with a medical molding facility and operations overseas allow this producer of high cavitation valve molds for the medical industry to grow and continue thriving.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More