Metro Mold Redefines Role of Supply Chain Partner

The Minnesota moldmaker has undergone a transformation it says is the result of both organic growth and strategic acquisitions.

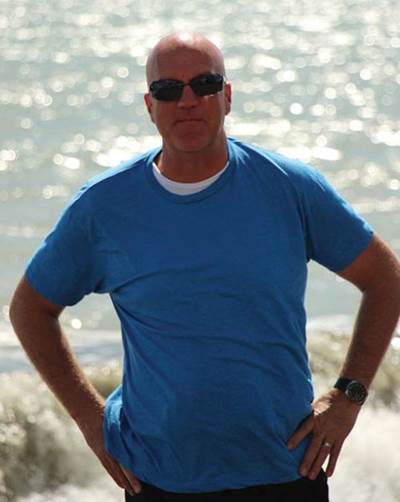

Leadership, company culture, diversity of experiences, always seeking out that next business opportunity. These are the characteristics that define the focus of Metro Mold & Design of Rogers, Minnesota. From humble beginnings in moldmaking in 1973 to the well-diversified and successful full-service manufacturer it is today, the company has undergone a transformation that, according to newly appointed CEO Greg Heinemann, is the result of both organic growth fueled by the desire to continue into new markets and strategic acquisitions. Acquisitions such as custom plastic injection molder Critical to Function in 2003; Accutech Mold and Engineering, a machine shop located in Little Falls, Minnesota, in 2006; and ICM Plastics, which added thermoset plastic molding and extrusion blow molding capabilities to Metro Mold’s repertoire also in 2006 all supported Metro Mold’s growth into new applications.

Heinemann, who is like-minded about how to expand in the future, explains: “We stay current with new technology, trying to maintain an average life of equipment at fewer than five years. The biggest change we’ve undertaken has been to focus on customer objectives rather than on the parts themselves. Also, globalization has made us more disciplined about saying no to projects that don’t fit our core capabilities.

“Expansion plans for the future are looking at emerging markets,” he continues. “However, between infrastructure, workforce and changing geographic preferences of customers, deciding where to put down roots is a challenge. We’re working towards creating a model that is agile and easily adaptable for radically different geographies as OEM’s are increasingly asking for overseas options.”

A Culture of Leadership

Metro Mold has embraced a business philosophy based on leadership and redefining the standards of excellence that it believes OEM customers should expect from their contract manufacturing partners.

Leading the charge is Heinemann, who is quick to identify himself as a business leader, not a manufacturer. His passion for developing leaders is why he surrounds himself with individuals whose competencies in engineering, design and manufacturing far outweigh his own.

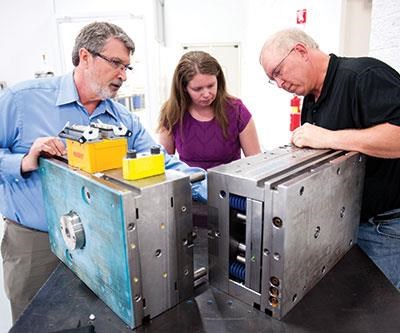

“Our chief competitive advantage is Metro Mold’s team of unique problem-solvers who come from different backgrounds and experiences,” Heinemann explains. “These teams take a two-pronged approach to every project that consists of 1) asking the right questions that lead to better results for customers, and 2) giving all individuals within the team the chance to lead—allowing people the freedom to share their insights and serve as true subject-matter experts, rather than simply following orders from an executive team.”

For example, involving an injection molding expert in a project requiring machining can lead to a unique set of questions that illuminate a new perspective on a problem. That new perspective frequently delivers the breakthrough to a customized solution that meets the business goals of the customer, Heinemann says.

“These customized solutions can include steps for simplifying the supply chain, combining or running parallel processes, increasing automation, and identifying problems early on to avoid costly ‘redos’ or outright failures as products are brought into production,” he says.

Metro Mold also recently launched its “Manufacturing the Impossible” program in which it leverages the diverse backgrounds of its team members to figure out the best way to manufacture a product that others might deem impossible. These projects frequently involves parts with tight tolerances and complex geometries, and require the utilization of materials in unique ways, often beyond what was thought possible. The goal is to help customers achieve business objectives, like developing the next generation of their products, or radically lowering costs to penetrate price-sensitive markets.

For one customer, this meant changing raw materials, which required a hybridized approach involving both machining and plastics processing to achieve a highly engineered finish, combined with difficult geometries and tolerances measured in microns. For this customer, cost reductions associated with the new process allowed it to enter a market with a product line that offered superior performance at an economically viable price point. Absent Metro Mold’s solution, cost represented an insurmountable barrier to entry.

“We recognized an unmet need in the marketplace for a supplier that can go beyond challenging parts to make the truly impossible,” Heinemann says. “The goal is to support OEMs in the rare circumstance when their current supply base simply cannot manufacture the part as designed and where redesign would undermine the strategic objectives of the project.”

Simplifying Complex Processes

Metro Mold sees its ability to simplify complex manufacturing processes as another major milestone in its quest to redefine its role as an effective and valued supply chain partner.

“Too often, complicated organizational structures and work flows lead to wasted time and resources, and, even more critically, divert focus away from providing meaningful solutions to the real challenges customers face when manufacturing complex parts,” Heinemann says. “At Metro Mold, we strive for simplification; we work to consistently produce breakthrough solutions that take costs out of large programs and deliver successful outcomes.”

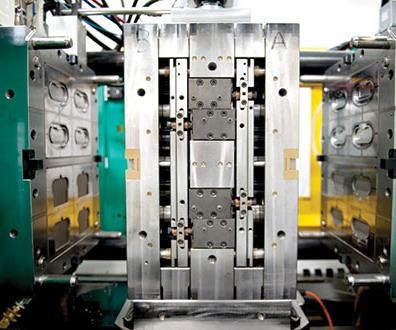

Besides daily status meetings, Heinemann identifies several technologies as critical to the company’s overall success: the Epicor enterprise resource planning (ERP) system to seamlessly manage operations, and RJG Inc.’s eDart process control system and Decoupled III Molding process, which uses instrumentation and data collection to monitor cavity pressure and temperature to improve process repeatability.

Heinemann says agility is the key to Metro Mold’s future success. “We’ve invested significantly in processes and people to drive creative thinking,” he explains. “Agility is the key to our future, and we’ve built a solid foundation to adapt to the ever-changing demands of our customers. We see a lot of change happening in both our workforce and the workforce globally. The companies that are successful will be companies who can quickly educate or re-educate their workforces, both domestically and abroad.”

Related Content

How to Supply Cooling to Additive Tooling

Additive tooling provides limitless options for cooling a mold’s difficult-to-cool areas.

Read MorePrecision Micro Finishing Tools Supply Machine, Mold and Die Operations

Titan Tool Supply has made available 100+ products for immediate online order or shipment from stock, supporting advanced manufacturing requirements.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreRead Next

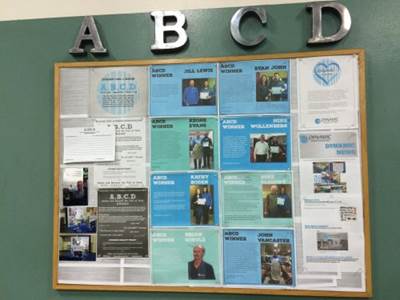

Above and Beyond the Call of Duty

For this year’s Leadtime Leader runner-up, the “ABCD” award is a key part of building camaraderie and ensuring a culture of ownership. Here are a few examples of recent winners.

Read MoreCreating Culture

Cultivating a team environment lightens the load on the individual person and distributes it among many, enabling faster lead times and better-quality products.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More