Maximum RPM Machining: Necessities of High-Speed Moldmaking

Mold shops will thrive if they practice an ‘all-aspects’ process to HSM, which includes the machine, cutting tool, toolholder, proper balance and application support.

The need to maximize machine utilization and capability is a constantly increasing one. Modern machine tools with spindle speeds of 60,000 to 80,000 rpm represent real opportunity to achieve those goals, and are a big part of the ability to achieve high-speed machining (HSM). The definition of HSM has been evolving and can include a combination of factors such as cutting speed, spindle speed and federates; however, it is commonly defined as light depth-of-cut machining at or above 15,000 rpm, or greater than 1,000 feet per minute, depending on cutter diameter. But, lightning-fast spindle speeds and table speeds are just one part of the equation. In order to shift into HSM, manufacturers also need to take a hard look at cutting tools, toolholding and good old-fashioned application expertise.

Cutting Tool Requirements

To permit for these maximum rpm applications, cutting tools have to be precise and long lasting, or more accurately, predictable, especially in unmanned operations. They also have to be capable of holding tolerance at these high speeds, and resist deflection and vibration especially in applications with longer overhangs. Balance, edge preparation, geometry and cutting tool (edge) material or grade all contribute to precision and life. Different tool shank materials also are to be considered and include steel, Densimet and carbide, with carbide being the most rigid.

Since cutting tools wear at varying rates during the machining process, manufacturers have to know the usable lifecycle—the point at which the cutting tool needs to be indexed, reground or replaced depending on the style of tool. Knowing and understanding predictable tool life helps shops make the most out of their cutting tools and, more importantly, get the most from the plant floor.

Cutting Tools and HSM

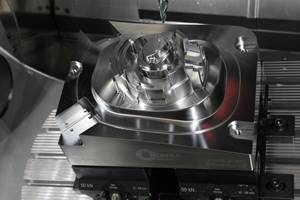

Many HSM applications are performed in the manufacture of molds and dies, using a variety of endmills. Enclosed pocket, cavity milling, and mold and die machining are all essentially synonymous and place heavy demand on the ability for machine tools to machine in multiple dimensions. Common operations include roughing, semi-finishing and finishing, with finishing being the most time consuming, requiring as much as 90 percent of the whole process. Advancements in cutting tools and the further development and use of HSM have allowed manufacturers to significantly reduce the overall manufacturing time, all but eliminating the need for handwork. True vertical wall machining also has been made possible through the development of 120-degree ballnose cutters that can effectively machine both down and up, further reducing machine cycle times.

The concept of precision cutting tools for HSM also has been adapted to meet the growing needs of very small applications and tight-tolerance inside diameter holes. To address these application areas a moldmaker should choose from a range of fine boring tools for precision internal machining applications in diameters from .012 inches to .315 inches. The connection technology in such tools is used for low runout and high part finish quality.

To complement the range of boring tools, an axial type fine boring head provides micrometer adjustments in increments of .0004 inches and vernier adjustments of .0001 inches on bore diameter. Precision manufacturing and super-fine adjustments permit operating speeds of up to 30,000 rpm / 4,920 sfm. The development of such tools further reinforces the importance of precision—both in the tool and the holding device.

Toolholding and HSM

Cutting tool challenges such as the ability to avoid chatter, deflection and minimize runout are equally determined by the rigidity, concentricity and balance of the toolholder. There are numerous choices for toolholding, and no one set answer for all applications. Among these are collet style, those that use a (arbor) set-screw, hydraulic holders and of course thermal shrink style. When considering HSM, balanced tooling is a must, and the highest amount of natural balance possible only serves to help the overall cause. Collet chucks are acceptable, but only if they are precision ground to avoid natural run-out.

For example, when looking at “D Type” collets (precision ground all over), you get completely static clamping, meaning it will not expand at high rpm. In contrast, if you were to use ER collets, there is a larger natural runout and as rpm rises, your clamping will actually decrease as centrifugal forces cause the collet to naturally open slightly.

Hydraulic chucks offer excellent transmittable torque and near perfect concentricity, so this style is an ideal choice with only one drawback—the units can be relatively bulky and can limit practical use in certain applications.

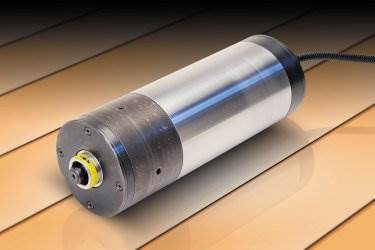

Among all of the toolholding choices, thermal shrink fit stands alone above the rest as the most accurate and rigid, making it the best choice for max rpm HSM applications. Shrink-fit systems consist of a machine with a thermal induction coil and a choice of cooling station configurations, and a range of special holders that can shrink and ‘unshrink’ a virtually unlimited number of times. The process focuses heat to the nose of the holder to expand the inside diameter of the holder and allow the cutting tool of choice to slip inside. As the nose cools, it contracts and becomes one with the tool. Balancing and presetting also can be accomplished. Unlike any other method of holding, shrink fit allows the highest torque transfer, accuracy of 3 micron at a 3X length to diameter ratio and flexibility to reach areas where other tools would simply be impractical.

There has been much debate about the different taper types, and arguments can be made for each as they all have their strengths. Judging a back-end solely on repeatability, weight and capability for high speed, would lead us to accept that HSK is the most ideally suited for HSM; however, this can change depending on shop conditions and several other factors, so all must be considered during evaluation.

Balance and HSM

With machine tool capability a given, and the proper choice of cutting tool and toolholder being made, HSM is a snap, right? Not exactly. Particular focus must be given to the assembly of tool and holder. The fact that each may be inherently balanced doesn’t translate into them being balanced as an assembly. Balancing must therefore be done after the tool and holder are connected. That holds true for whatever combination you choose, and is really a key to effective and efficient machining even in lower speed, heavier cut applications, but ultimately critical for HSM.

To produce fine finishes and maintain long and predictable tool life while performing high-speed applications, you must run balanced tooling. Part of understanding the balance issue is knowing what the maximum “un-balance” your machine can withstand. As a general rule of thumb, it is accepted that a maximum of 3 grams per millimeter of unbalance is permitted in HSM toolholders. But, at very high spindle speeds (30,000+ rpm); it is not uncommon to require closer to just 1 gram per millimeter. This can be compared to a standard, generic endmill holder, which can have as much 250 grams per millimeter unbalance. Depending on the actual rpm used, this can be the difference between catastrophic failure and complete success. Balanced tooling will yield better results at any rpm, but becomes an absolute necessity when considering HSM, having the ultimate impact on productivity, quality, consistency, predictability and safety.

All Aspects Approach

The last leg of the stool is still grey matter. The significant advancements in machine tools, cutting tools and toolholding all still require the proper evaluation, selection and application that can be done by experienced machinists and application engineers. So, before you rev up the spindle, consult with your machinists and application specialists to ensure a safe and productive operation.

HSM will continue to have a major impact on productivity and profitability across many markets like mold and die, but also automotive and aerospace. From very soft metals and non-metals to 60RC+ die steel, the success of many shops will hinge on HSM capability. And those that practice an ‘all-aspects’ process—including the machine, cutting tool, toolholder, proper balance and application support—will thrive.

Related Content

Building Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreProducts and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreRead Next

HSK: The Critical Link in High-Speed Milling

As high-speed machining and milling becomes more popular, moldmakers are looking for alternatives to their traditional low-speed toolholders.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=970;quality=90)