HSK: The Critical Link in High-Speed Milling

As high-speed machining and milling becomes more popular, moldmakers are looking for alternatives to their traditional low-speed toolholders.

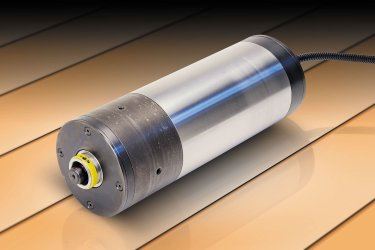

As moldmakers learn the benefits of running small diameter cutting tools at high rotational speeds, the toolholding system for the machines that run those jobs becomes a key success factor. The HSK tooling system offers tremendous advantages to mold shops in terms of accuracy, repeatability, weight and fast tool changing cycles.

Originating in Germany in the later 1980s, the HSK family of standard toolholders was developed to meet the needs of ever increasing spindle speeds. Steep-taper tooling, using CAT V-Flange, SK and BT toolholders, had begun to show its limitations at spindle speeds in excess of 8,000 rpm. Already widely accepted in Europe, HSK is still relatively new in the United States. American automotive and aerospace manufacturers have been the early adopters of the technology.

Less Is More

Holding the hefty mass of a size 40 or 50 CAT/SK/BT steep-taper toolholder in your hand gives you a certain sense of security. By comparison, the HSK adapter of comparable size seems quite light. At high rotational speeds, though, the HSK system - toolholder and receiver - has the dynamics of motion working with it, much as the seemingly light structure of an airplane is strong in flight.

The key element of the design is dual-surface location of the toolholder when it is engaged in the receiving member of the spindle. The holder is located radially by the fit of the toolholder's 1:10 ratio tapered shank O.D. with the receiver's matching taper I.D. Simultaneously, the holder's flange comes face to face with the spindle nose's front flange for positive axial location. This positive seating of the flanges sets the HSK system apart from the CAT/SK/BT products, which locate on the 7:24 ratio taper alone.

As spindle speeds increase, there is a tendency for the spindle shaft and its receiving taper to heat up and grow, both radially and axially. Radial growth in a spindle using CAT/SK/BT steep-taper tooling allows the tool retention mechanism to pull the toolholder deeper into the taper, resulting in a loss of Z-axis accuracy. At the same time, the mass of the toolholder may prevent it from warming as quickly as the spindle taper. The slower growth of the holder causes the solid fit of the taper to be lost and radial stiffness is lost, as well. The loss of the solid fit also opens opportunities for resonance - or chatter - to develop.

Spindles using the HSK system also are subject to thermal effects. What is different is how the HSK system handles them. Since the HSK adapter is located axially by flange-to-flange contact with the spindle nose, the tool retention system cannot pull it from its place. And since the HSK toolholder is hollow, its tapered shank will heat more evenly and grow with the spindle taper.

High rotational speeds also have a positive effect on the HSK design's tool retention system. Since the retention fingers are positioned to be inside the hollow area of an installed toolholder and grip outward, the centrifugal force of the rotation increases their grip, keeping the toolholder's flange tight against the spindle's nose flange.

The Payoff: Greater Radial and Axial Stiffness

The precision fit of the HSK adapters combined with the spindle and the compatibility of the HSK design and the forces at work in high-speed rotation all contribute to measurably better radial and axial stiffness than that of spindle systems using steep-taper CAT/SK/BT toolholders. The stiffness is what contributes to repeatable accuracy and high quality surface finish.

HSK's stiffness advantage begins with the tool retention system, mentioned above. Its clamping force is typically double that of CAT/SK/BT designs. The simultaneous, two-surface seating and the basic precision of the HSK adapters and receivers finish the job. Testing has revealed the HSK interface's radial stiffness advantage to be up to five times that of steep-taper tool systems. The greater the radial stiffness of the assembly, the less chatter and tool deflection that can occur.

Outstanding axial stiffness - a result of the flange-to-flange mating - of the HSK holder and adapter also is measurably superior to the CAT/SK/BT.

Applying Torque to the Cutter: A Range Of Choices With HSK

The HSK system is a family of designs, all featuring the 1:10 ratio mounting taper. Six types of toolholders give users an opportunity to choose the toolholder best suited for their application. A range of sizes in each type of holder rounds out the offering with a total of 35 holders.

Selection of a particular type or style of adapter can be based on the amount of torque to be applied to the work, the speed range necessary for the job or whether automatic or manual tool changing cycles are desired. From the standpoint of torque transmission and spindle speed, user's choices are as follows:

- HSK adapter types A and C are designed for moderate torque and moderate to high rotational speeds.

- HSK adapter types B and D are designed for high torque and moderate to high rotational speeds.

- HSK adapter types E and F are designed for low torque and super-high speeds, with heat-shrink tooling.

Toolholders intended for automatic tool changing applications include orientation guides.

Fast Tool Changes - Automatic or Manual

Automatic tool changes in machining centers are faster with HSK tooling than comparable sized CAT/SK/BT steep-taper toolholders. The tapered mounting shank of the HSK design is approximately one-half the length of the traditional tapers. The low-mass design of the HSK units eases braking and handling issues, as well.

Manual changing of adapters also is fast and easy. HSK toolholders feature simple release/lock systems. They also are shorter than their automatic change counterparts and are potentially stiffer and more accurate in critical applications.

HSK Type A and B holders have the additional advantage of being suitable for both manual and automatic tool changing cycles. These two styles also have provision for installing a microchip that can share cutter information with the machine's CNC controller.

More HSK Benefits

Balancing HSK adapters is no more difficult than balancing traditional CAT/SK/BT toolholders. Types E and F, the holders for super-high-speed applications, were designed with ease of balancing in mind.

Minimizing tool crash damage is another benefit of the hollow HSK adapter design. When the energy of a serious crash is transmitted to the toolholder, it will break, protecting the spindle, similar to the way "crumple zones" on automobiles absorb energy to protect passengers.

The cost of HSK tooling is coming down. Tool manufacturers are becoming familiar with the fine points of producing the standardized designs and overall demand for the product line is increasing. As acceptance increases, this trend will continue.

The Bottom Line

HSK is a system of toolholders that can handle a very wide range of machining needs, both in the traditional low-speed/high-torque applications and the increasingly productive high-speed/low-torque world of hard milling. Its advantages in stiffness and accuracy have been clearly shown. Steep-taper CAT/SK/BT tooling that has served so well over many years in low-speed cutting is not going to get the job done in the future. The time to start getting on-board for the future with HSK is now.

Related Content

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

HSK Fact and Fiction

Get the facts on what to consider when purchasing and using HSK tooling.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More