Making the Right Mold Material Selection for Thermal Management of Molds and Inserts

The engineering of a mold greatly determines the performance of the plastic injection molding process, because it directly influences cycle time and process productivity. Here we review why productive thermal management of a mold is essential in determining the cost-effectiveness of the molding process.

Share

Read Next

In plastic injection molding, the performance of the heat transfer from the molten plastic to the cooling media through the mold determines the cost-effectiveness of the process. For a given application, understanding the mechanism of heat transfer in different zones of the mold is necessary to design and ultimately build an effective tool.

On one hand, this allows for optimization of the cooling system configuration. On the other hand, it helps with selecting the right material for the mold and/or for the different zones of the mold in order to optimize cooling time and minimize scrap due to warpage or under-fill.

In addition to the thermal requirements, mold materials need to respond to mechanical and tribological demands of the mold, which may vary throughout the tool geometry.

The thermal properties of the mold play an important role in improving the heat transfer from the molten plastic through the mold and in reducing cooling time—locally or generally.

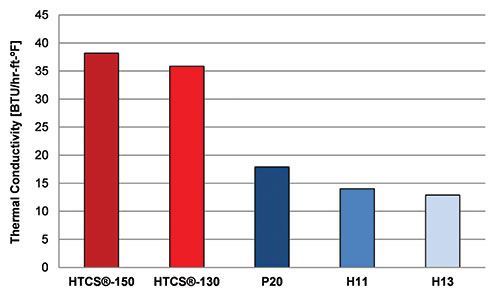

For several decades now, the thermal conductivity of conventional tool steels used for plastic injection molding has been limited to 12-20 Btu/(hr•ft⋅°F), the lower range corresponding to tool steels presenting higher mechanical and tribological properties. However, tool steels that provide thermal conductivity up to 35 Btu/(hr•ft⋅°F) , commercially known as high thermal conductivity steels (HTCS), should be considered.

Two grades of these tool steels, HTCS-1 and HTCS-2, have been used for plastic injection molding. Both present thermal conductivities of more than 35 Btu/(hr⋅ft⋅°F) (see Figure 1), while the mechanical properties are close to those of conventional hot-work tool steel H13. HTCS-2 is a remelted tool steel with a high degree of polishability, and HTCS-1 is a powder metallurgy tool steel with moderate polishability but very high abrasive wear resistance. The latter grade can be used for molds that present problems with abrasive wear (plastic reinforced with fiber glass), which do not require a very high degree of polishability.

Moldmakers and component producers looking to optimize the thermal management of the mold, process productivity and tool durability while molding plastic components reinforced with abrasive fiber glass should consider these tool steels.

A promising feature of these tool steels is that they can reach a hardness level of more than 50 HRC while maintaining a very high thermal conductivity, making them candidates for not only tackling thermally related problems (for example, productivity, part warpage, poor temperature distribution, cooling, etc.), but also mold durability, especially when the plastic is reinforced with abrasive glass fibers.

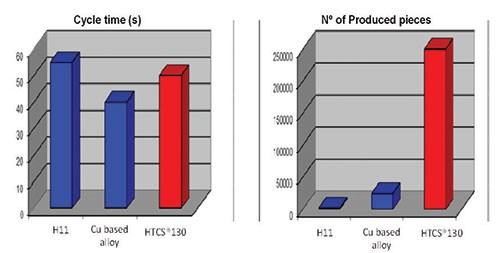

Figure 2 shows that the best compromise between mold durability and cycle time for an electrical connector (example supplied by STM Stahl) was a mold made of HTCS-2 (compared with H11 steel and a copper-based alloy).

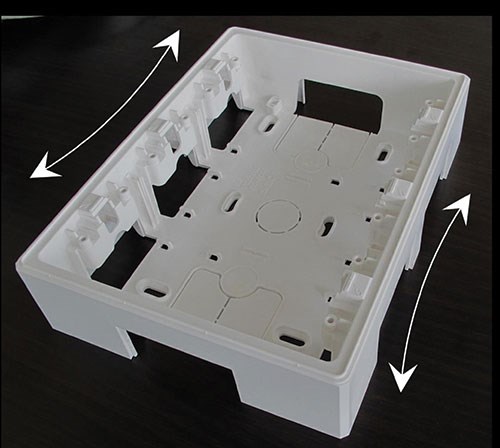

These high thermal conductivity steels have also been applied in molds where poor distribution of the temperature over the surface of the mold generates warpage and filling problems. This is because the high thermal conductivity also indicates a high diffusivity of heat through the mold in all directions. So, for difficult mold geometries, especially larger molds, a good distribution may be obtained when using high thermal conductivity steels. As for size, molds or inserts of 47" × 32" × 39" and larger can be produced with these tool steels.

Figure 3 shows a high-volume electrical box. In this application with conventional tool steels, the rate of scrap occurrence was very high due to the warpage produced from bad temperature distribution over the mold surface. This problem was solved by switching to HTCS-1.

Summary

The very high thermal conductivity of these tool steels enable them to be used to tackle long cycle times, poor temperature distribution and mold durability in plastic injection molding, especially for fiberglass-reinforced plastics. The grades presented here are candidates for mold designers and moldmakers to consider using when dealing with the thermal problems of the mold and to improve the cost-effectiveness of the process. For plastic injection molding, these grades can be used to build complete molds as well as to build big and small inserts with all the hardness levels required for various applications.

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More