Linear Drives Increase Speed, Accuracy

Two distinctive capabilities on the new machines each have a great impact on DTE's time to market— linear drives and five axis.

Since 1984, Die Tech & Engineering, Inc. (DTE; Grand Rapids, MI) has carved a niche for itself building plastic injection molds as well as aluminum and zinc die cast dies in the automotive, office furniture, gaming, motorcycle and appliance markets. In order to meet the continued challenges of dimensional tolerances without sacrificing speed, cost or accuracy, the company started using HSC-series linear drive machines from DMG/Mori Seiki (Hoffman Estates, IL). Since its first purchase in June of 2011, DTE has installed two HSC 75 linear and one HSC 105 linear machines, and another HSC 105 is on order for delivery this month. That's four very high performance machines in just over a year.

DTE currently employs 50 people—10 of which are degreed engineers as well as four engineering interns. It is not surprising that the work the company produces is highly accurate. According to DTE President William Berry, part print accuracies are typically in the ±.05 to .1mm range (.002" to .004"). "These machines actually work very consistently to tenths of a thousandth, so the machine precision helps us speed through things faster," explains Berry. "In the cases where we have tight tolerances to less than a thousandth (.025mm), we work with total confidence."

Challenges presented in doing this work are centered on keeping costs down while maintaining quality. “Time-to-market is increasingly important,” Berry emphasizes. “We need to be globally competitive when quality requirements are higher than ever.” Two distinctive capabilities on the new machines each have a great impact on DTE's time to market— linear drives and five axis.

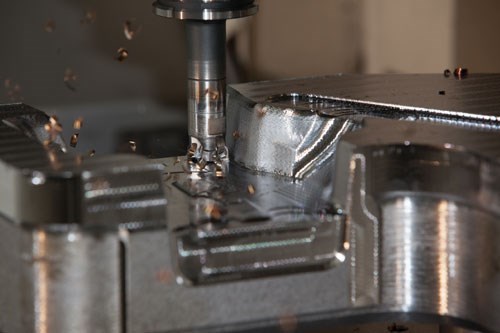

“The linear machines allow us to employ high speed and high feed tool technology—enabling rough to finish on the same machine,” says Berry. “The linear machines from DMG start with highly accurate machine frames, add high speed spindles, eliminate ballscrews and replace them with linear motors to increase speed, accuracy and acceleration. An additional benefit is the expected useful service life as the linear motors have no moving parts, unlike a ballscrew servo system.

"Five-axis simultaneous contouring reduces set-up times—which also results in quicker leadtimes and higher accuracy,” Berry continues. “Accessing features on five sides of a part—at any angle—all from one setup, is a huge advantage. Complex sine plate setups are a distant memory for us."

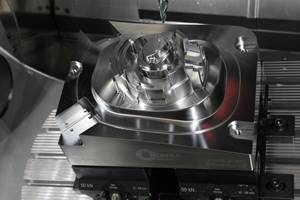

Another key to DTE’s success with five axis has been its pallets. Approximately 12 years ago the company implemented an EROWA (Arlington Heights, IL) pallet system throughout the shop, which included not only machining centers, but also EDM and inspection. “When a part is designed, that design includes the pallet and it stays on the part until it is ready for assembly,” Berry notes. “This virtually eliminates dial indicators in the shop. The staff can work with confidence knowing that each part is on location as soon as it is located in its pallet receiver.

Another key concept with pallets was the implementation of 100 percent collision checking of all cutter paths prior to machining, Berry maintains. “With five-axis positioning and contouring, things happen fast,” he states. “Crashes could be costly. With pallets, we always know where a part is in its work zone and on the machine, and it has been verified before machining starts."

"The kinematics of these new machines are just terrific, giving us virtually perfect blends on contours in all positions," asserts Berry. “In the same—or less—machining time, we have better looking, more accurate parts, which has also allowed us to dramatically reduce EDM operations. We EDM less by using 28k spindles with cutters as small as .5mm (.020") or less in diameter. In an increasing number of our operations, there is little or no polishing needed.”

The new machines allow DTE to realize the true potential of all the latest technologies—high speed and feed cutters and inserts, high speed spindles, laser tool measurement, pallets, five-axis positioning and contouring, and linear drives, Berry reports. “Each of these technologies is exciting and can add productivity,” he states. “Together, they bring out the best in each other, providing us a synergy that directly reflects in our bottom line."

The impressive performance of these machines has had one additional benefit, customer recognition, notes Berry. "This level of performance is outside the realm of normal equipment in a mold shop," he comments. "Our customers need innovative solutions to compete in a global business climate. They see the difference and like having a partner on the cutting edge.

“I strongly recommend combining five-axis technology with linear motors,” Berry concludes. “The results are compelling. Make sure you have a strong programming group and purchase simulation software with collision detection and expect to start on a whole new path of learning techniques and methods to exploit this technology.”

For More Information: Die Tech & Engineering, Inc. (DTE) / (616) 530-9030 / s.berry@dietech-gr.com

Photos courtesy of DTE/Todd Schuett.

Related Content

Ten Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreSpeed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreRead Next

Video: Minimizing Mistakes with Laser Scanning CMM

Die Tech & Engineering uses its scanning to CMM to avoid errors by inspecting electrodes prior to EDM.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More