Mark and Corey Brown both believe that patience and persistence are two key qualities to surviving their nine-year transition. Photo Credit, all images: Burger & Brown Engineering.

“What do you call it when Batman skips church?” asks Mark Brown, CEO of Burger & Brown Engineering. He chuckles as he quickly replies, “Christian Bale,” demonstrating the humor he’s retained during a challenging nine years of transition preparation and planning to his son President Corey Brown.

Emphasizing the need for humor during this journey are some staggering statistics related to transitioning a family business to another family member, which is common across the moldmaking community. “The success rate of a first- to second-generation transition is 32%; second to the third generation is 11% and third to the fourth generation is 2%. So, family dynamics certainly come into play and is one of several challenges to figuring out the way forward with a small business to the next generation,” Mark says.

In a nutshell, to grow a company, both Mark and Corey agree that the owner must be nonexistent, so everything is able to operate without that person. It is with that in mind that this duo developed a plan (albeit not perfect) to work together up until the official day of transition in 2023 so as to reach a point where they are not working in the business, but on the business—meaning that each employee can function properly, and the team maintains its level of customer care and company growth without their hands in every aspect of the business.

Setting the Stage

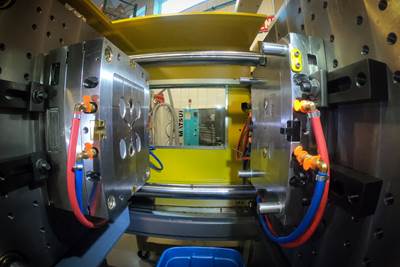

Burger & Brown Engineering is an engineering-driven manufacturing company focused on close-tolerance, complex work for the defense, aerospace, medical, semiconductor, gaming and food and beverage industries, as well as the U.S. Department of Energy (DOE). They offer injection molding, conventional machining, micro machining, Swiss machining, industrial automation equipment (jigs, fixtures, prototypes), welding, contract inspection and contract engineering.

Burger & Brown Engineering is an engineering-driven manufacturing company that added structure to its culture to help manage growth. As part of the plan they hired a consultant to launch a culture initiative that formalized the company’s core values and posting them throughout the shop for everyone to see.

Burger & Brown also develops, designs, manufactures and tests its products in pre-production settings. If they like a product, they move it into production and offer it to the masses. About 35% of what Burger & Brown does is proprietary products, offering engineered solutions to the injection molding industry, including ancillary equipment supporting mold cooling, in-mold sensors and ejector tie-in systems. Currently, they have 16 trade names and are working on their 11th patent.

Burger & Brown offers injection molding, machining, industrial automation, welding and contract inspection and engineering. They also design, manufacture, test and sell their own products.

Phil Burger founded Burger & Brown Engineering in 1978 as an engineer helping businesses automate their processes. He then started building molds for the injection molding industry and offering contract machining. Mark Brown joined Burger in 1989. He left for five years and then returned in 1994 with the intent to buy the company. He became majority owner in 2005, completing the buyout in 2006. Since that day, Mark has been focused on growth, including a succession plan for his son, Corey.

Mark performed an 11-year transition when taking over Burger & Brown. Discovering that that transition period had been too long, father and son settled on nine years instead. It is now year seven into this nine-year succession plan.

Making the Move

In 2014, as Mark was staring at the age of 50 and realizing that he did not want to be worrying about the future of the business and its customers, Corey, an enthusiastic 26-year-old at the time, came on board.

“I was always told that I’d never work for this company, so I went out on my own to gain manufacturing experience. It was my father’s way of making sure I could survive on my own. He wanted to be sure that I was able to deal with the real world,” Corey says. He was a plant engineer for an oil processing company and a project engineer for a bulk material handling company. In 2014, he came into Burger & Brown when a project engineer position opened up. Both Corey and Mark committed to seeing how it would go and how he would interact with the shop floor. They also agreed that if it didn’t work, Corey would leave because family comes first.

Crucial lessons Mark and Corey have learned so far in this transition include opening up to outside input, being confident in your decision-making and accepting that if you make a mistake, fix it and move on.

“We’ve always tried to keep our father/son relationship out of the business. But I can’t deny that everyone is watching you. So at some point, I tried to prove myself a little too much to show I was not only here for a paycheck,” Corey says.

In the second and third years of the transition, Corey went from the engineering manager in 2015-2017 to vice president (VP). After that, he moved out of engineering to experience the rest of the company, becoming president in 2021.

“I took on as much as I could to get involved in everything and would jump in whenever I could while working in the engineering department. Then when I took on the VP role, I had to transition stuff off my plate, which proved difficult because we were growing at the same time,” Corey says. It’s a constant battle, but one he is up for facing as the transition moves forward. Mark has documented the transition up until this point in a journal, and both he and Corey have put together some advice for shops facing a similar succession plan timetable.

To grow a company, both Mark and Corey agree that the owner must be nonexistent, so everything is able to operate without that person.

Stepping into a Successful Family Transition

1. Keep emotion out of the decision-making process.

Mark’s direct business decision-making style was at the core of Corey’s frustrations, while Corey’s perfectionism was at the core of Mark’s frustrations. Corey believes there is always room for improvement, and although Mark admits there is always room to improve, you also need to “roll with it a little bit.”

For example, to continue its growth trajectory, the company needed a new ERP system. Mark wanted to jump in and figure it out as he went along, understanding that the initial data would not be perfect, but that it would improve as the company evolved. Corey, on the other hand, wanted to delay the investment so as to have everything perfect from the start. He thinks if you don’t do it right the first time, it’s twice as much work to go back and change it. Corey reluctantly agreed to move forward; Burger & Brown is now five years into using its new ERP and can rely on the data.

“Through this process, Corey became more patient and accepting of imperfection. Things are going to reveal themselves in time, so you have to keep battling every day to make it work,” Mark says. “Patience, persistence and optimism are vital.”

2. Consider all generations in your management and communication approach.

Change is hard, but Burger & Brown was also growing. Transitioning to the next generation only made matters more complicated. Today, the company has 70 employees, a 20-person increase from the 50 employees when Corey started. In addition, they have an average tenure of seven years with some reaching more than 20 years, which alone can make any change a challenge. Plus, the workforce represents four different generations—baby boomers, Gen Xers, millennials and Gen Zs—for which communication and management styles come into play.

For example, Mark’s management style is level-headed with little to no emotion, believing that leaders must be the rock during difficult times. Corey’s style—initially youthful—created conflict between father and son, employees and other management. His work ethic and intelligence were strengths from the start. It was his people skills and emotion management that needed improvement.

Mark believes that you let youth run its course and maintain patience with the process. However, his patience started waning around the five-year mark, as he and Corey were having heated discussions regularly.

To remedy this, Corey went out on his own and found a group called Vistage to get an outside perspective on how to change his approach. As a result, his management style changed and he’s even brought back valuable insight to Mark.

“A lot of the frustration came from the simple fact that we’re a different company than we were 10 years ago. The expectation of how a leader should run the company changed. This was a struggle for Mark and I had to figure out how to work around that while growing and managing a transition simultaneously,” Corey says.

3. Be transparent with all stakeholders.

The core element to the transition culture is Mark and Corey’s transparency with the team, not just internally, but with all stakeholders—customers, vendors and associates. It’s important to keep them up to date because if you don’t give them a narrative, they’re going to come up with their own narrative, and that’s dangerous.

An essential part of the transition is Mark and Corey’s transparency with the team, not just internally, but with all stakeholders—customers, vendors and associates.

Mark and Corey frequently come together to talk about significant changes, new investments, health insurance and other important topics. For example, two years ago, they made a $1.7-million investment in equipment and personnel, and again in 2021, reaching more than one million dollars in new equipment and resource investment.

4. Create internal and external support groups.

The team is critical to success. A support team is crucial during a transition and getting a third-party perspective is essential.

Support outside of fatherly guidance comes from Burger & Brown’s Executive Team—comprising the sales manager and general manager—that deals with the day-to-day operations, sales and new opportunities. In addition, Corey, with the support of a Steering Team, guides its culture and the decision-making process. This includes the human resources manager, general manager and sales managers.

Another critical layer of the team is one Mark and Corey have strategically developed over the past 36 months—the Leadership Team, comprising the primary managers who understand the company’s growth goals and hold monthly meetings.

“We value our team and what they do. We invest back into our team, either through training or new equipment and new technology. We want to ensure that they have the best tools to support our customers for the next 15 to 20 years. In addition, we want to maintain our reputation as a precision manufacturer who provides for our customers,” Mark says.

Burger & Brown’s critical third-party perspective is Vistage, a global peer group for C-level executives and business owners that offers perspective from other people in other industries that have potentially gone through the same things to aid in making better decisions. Topics include human resources, meeting structure and strategy.

This father son duo developed a plan to work together up until the official day of transition in 2023 so as to reach a point where they are not working in the business, but on the business.

“There are no competitors, avoiding any conflict of interest, but we are both very private, so sharing is difficult for us with people outside the company. It was a big deal to sit down and discuss business issues with the group and grow trust,” Corey says. Regardless, they are glad they stuck it out. Both Mark and Corey says they have learned so much by leaning into support on the outside.

Further, two years ago, Mark and Corey were very deliberate in adding structure to the culture to help manage the growth in the workforce—with a team comes culture.

“When you are smaller, it’s easier to have conversations to explain your culture, but as you grow in numbers, that gets watered down. So we hired a consultant to help us put our core values down on paper—launch a culture initiative,” Corey says.

They didn’t actually change anything. They just finally wrote down what the the company was doing. They formalized the culture by posting the core values and purpose statement throughout the shop, so it is on everyone’s minds daily.

Today, Corey is still extracting information from Mark that he doesn't even realize he has and waits for the transition date. They are committed to working on the business and growing the team to work in the business.

Working On the Business

The final deadline is now 18 months away and although Mark still goes into the shop Monday through Thursday, they are transitioning that out. Mark is now there only as support and to help Corey understand the bigger picture. That is, financial matters to help him identify ways to improve.

“I’m working on those bigger picture items such as working with the banks and the books, and ensuring the leadership team is stable and strong as we move forward to support Corey’s efforts,” Mark says.

Corey continues to extract the information from Mark that he does not realize he has and waits for the date. “We’ll be connected at the hip for the next 18 months,” Corey says and smiles. “He’s working on the business and helping me work on the business. We’re growing our team to work in the business.”

Related Content

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreMold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

Read MoreEden Tool and Eden Manufacturing: A Story of Resilience, Growth and Innovation

This critical parts manufacturer, founded on solid tooling fundamentals, didn’t get derailed with the unexpected passing of the owner because leadership was already building a solid business, not just a good tool shop. Here’s how they managed change incrementally… and they’re not finished yet.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreRead Next

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreManaging a Team Through an Acquisition

The operations manager for a Pennsylvania mold manufacturer shares lessons learned from a recent acquisition.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More