Index Completes One of Its Best Years

Employment and new orders lift the Index, at 55.4 in December.

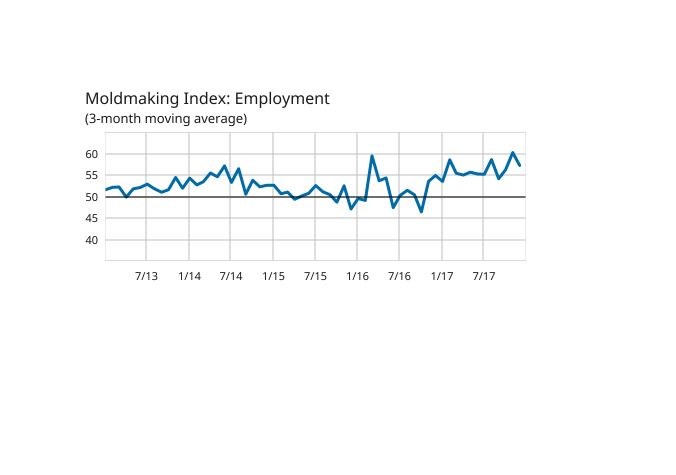

Registering 55.4 for December, the Gardner Business Index (GBI): Moldmaking expanded at a faster pace than during the previous month. For the calendar year, the Moldmaking Index averaged 55.5, marking 2017 as the best calendar year for the Moldmaking Index since its inception. During the year, the Moldmaking Index exceeded a reading of 55 in seven of the 12 months. Before 2017, the Moldmaking Index had exceeded a reading of at least 55 for only one month in both 2012 and 2014. In comparison to the same month one year ago, the Moldmaking Index increased by 6.5 percent. Gardner Intelligence’s review of the underlying data for the month indicates that employment, new orders and exports lifted the Moldmaking Index higher while production, supplier deliveries and backlog pulled the Moldmaking Index lower. No components of the Moldmaking Index contracted during the month. Gardner Intelligence is monitoring the unusually sharp slowing in the growth of supplier deliveries, which has fallen nearly 10 points since reaching a high of over 64 in October. Conversely, exports registered its strongest expansionary reading on record during December.

About the Author

Michael Guckes

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media. He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

MMT Chats: 4 Keys to a Successful Mold-Building Operation: Innovation, Transparency, Accessibility and Relationship

MoldMaking Technology Editorial Director Christina Fuges chats with Steve Michon, co-owner of Zero Tolerance in Clinton Township, Michigan, about the excitement of solving problems, the benefits of showing gratitude, the real struggle with delegation and the importance of staying on top of technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

.jpg;width=70;height=70;mode=crop)