Improving Ejector Plate Alignment

An alignment system can provide a more reliable mold by reducing wear on the moving ejector components.

When it comes to mold alignment, gravity is the challenge. Gravity pulls down on all moving parts of the mold and machine and introduces extra wear on those moving parts. Machine manufacturers have addressed this problem by adding machine ways (flat surfaces) to support the machine’s moving platen. Machine ways or linear bearings built into the machine also support the center section of modern stack molds. Modern stripper-plate molds use a bar-style interlock to support the stripper plate and prevent gravity from pulling it out of alignment with the rest of the components (even though there are four guide pins attempting to keep the plate supported). So steps have been taken to properly support every section of the mold and machine—except the ejector plates.

Understanding that a flat surface provides the best support and guidance to other sections of the mold and the machine, I thought: Why not apply this same concept to the ejector box and the ejector plates? The “next step in guided ejection” is an ejector plate alignment innovation that keeps the ejector plates perfectly aligned regardless of the size or weight of the plates.

The idea for this system emerged from working on large 12-, 16-, 32- or 96-cavity molds with inner cores and sleeves that required accurate alignment to the B-side cavity. Traditional guided ejection systems use pins and bushings mounted in the ejector plate. As mold size increases, larger pins and bushings are needed that take up more of the molding area, and weight starts to become an issue. Designers are typically trying to fit the molded part into the smallest mold base possible. In doing so, they are designing around mold base essentials like guided ejection, pins and bushings. The ejector plate alignment system flattens these features out and moves them up to the center of the mold, where there is room around the sprue.

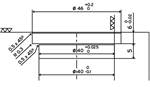

An alignment bar and wear pad make up this ejector plate alignment system. The wear pad is a precise one-piece design that accurately fits with the alignment bar. The design’s simplicity also accounts for the machining of the components and the mold base plates, easing their manufacture while still providing optimum support. The pockets in the plates are also designed to be machined in the same setup as the counter bore for ejector pins and additional screws. The alignment bars are on the center line of the mold base, minimizing the effect of thermal expansion. With larger molds the weight of multiple ejector plates is no longer an issue. All of this provides precise alignment and a more reliable mold by reducing wear on the moving ejector components. It also provides more useable space in the mold base.

So, with your next design project, take the next step toward building a better mold and consider the benefits of an ejector plate alignment system.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.