HSM Hikes Moldmaking Productivity

Achieving the full benefit of high-speed, hard-mold machining requires insight into tools and processes.

Competitive moldmakers trying to reduce turnaround times face a milling dilemma. Milling steel molds in the fully hardened condition saves time and slashes manufacturing costs by eliminating manual finishing work. However, today's faster, 40-taper milling machines typically have less spindle horsepower available to cut mold cavities in hardened steel. Traditionally, hardened materials have been milled with slow speeds and deep cuts that lengthen machining time. More productive HSM with shallower cuts and higher feeds and speeds actually hikes throughput yet reduces cutting temperatures and forces. Milling hardened molds with faster, less powerful machines productively requires a new approach.

Consider the shop machining a large cavity three inches deep to hold a mold insert. In the past, machinists would typically drill a hole into the block and then rough out the cavity with solid HSS or an indexable, long-edge endmill with large depth-of-cut capabilities. The high radial tool pressure generated by the long cutter engagement dictated very slow feedrates - sometimes as slow as one to two inches per minute. The radial engagement of the cutter also was limited - generally to 20 percent or less of the tool diameter. These constraints were the result of limitations on available machine power and the stability of the setup - spindle size and condition, workholding, toolholding, and so on. Slow feeds and speeds also preserved the life of cutting inserts and avoided frequent shutdowns for tool changes. That sort of safe-but-slow approach nevertheless costs you business in a market that demands shorter leadtimes.

In contrast, modern coated carbide inserts better able to withstand the high stresses and temperatures encountered when milling hardened stock have opened productive possibilities. To open the same cavity faster, use a round insert cutter with grade GC4020 carbide inserts optimized for hard materials. The hard-steel milling grade has a hard substrate protected by a heat-resistant coating to withstand the high loads and heat encountered in hardened stock. Round insert cutters also are able to ramp into the cavity without a starter hole - and they can sustain dramatically higher feedrates. With a 0.050-inch depth-of-cut and 1,300 sfpm, the modern cutting tool and insert combination achieved feeds of 200 ipm. Together, higher feeds and a simpler process reduced overall cycle time to produce the cavity by more than half.

Hard Cash

To cut costs and transform mold blanks into cash faster, today's moldmakers must mill steel hardened up to the mid-sixties on the Rc scale. Rough and finish milling mold cavities after hardening avoids the dimensional distortion of heat treating and the manual finishing work required to establish proper dimensional characteristics. Polishing remains a skilled operation that generates high labor costs and consumes precious leadtime. It also can make expensive scrap - a mistake can ruin the workpiece at the very end of the value-added chain.

The one true measure of moldmaking productivity remains the number of good molds produced per unit of work time - whether shift, day, week or month. Compared with the traditional approach to milling hard stock, the trend toward higher spindle speeds and shallower depths-of-cut increases throughput and can even improve metal removal rates. CNC programmed milling also provides tighter process control and more accurate, uniform components. Prehardened mold surfaces also can be milled to a high microfinish in a fraction of the time required for EDM to do the same finish.

With spindle speeds greater than 20,000 rpm and table feeds more than 200 ipm, HSM can achieve impressive results in overall process and component improvement. However, the shallow depths-of-cut and thin chips still make HSM metal removal rates lower than those achieved with soft metals. Based on HSM metal removal rates and the capacity of most machine tools, the maximum economical mold size for HSM is generally a sixteen-inch cube. The best candidates for HSM typically are relatively shallow molds without highly complex forms.

Positive Influence

Although HSM hikes moldmaking productivity, it makes special demands on cutting tools. Compared with soft metal machining, the high cutting forces and temperatures encountered when machining hardened steel at high speeds accelerate tool wear. To further complicate matters, milling cutters must withstand intense impact each time they re-enter hard stock. Shorter tool life is important only inasmuch as it impacts throughput. Though tooling generally accounts for just 3 percent of total manufacturing costs, frequent shutdowns for tool changes compromise productivity.

Modern cutting tools enhance productivity with higher throughput and longer life. Advanced cutting inserts now provide the hardness, heat resistance and impact toughness necessary to sustain reasonable tool life and recover time lost to tool changes. Advanced milling tools afford the reduced cutting pressure, low run-out and high-edge security necessary for HSM in hard materials.

Modern concept milling cutters improve throughput with freer cutting, positive-rake geometries and other innovative design features. They also reduce wear and tear on today's lighter machine tools - sometimes providing a totally new approach to tough jobs.

For instance, one shop adopted an innovative plunge rougher to cut an eight-inch deep internal pocket and peripheral features in a hardened block. Milling features in a block 11 in. x 16 in. x 24 in. with a conventional three-inch facemill took twenty-four hours. To protect the spindle and satisfy machine horsepower constraints, the facemill traveled the workpiece length and width and stepped down in 0.100-inch increments.

A more direct and efficient approach with a plunge cutter follows: the plunge rougher approaches the workpiece from above, penetrates to maximum depth and withdraws to step over for the next plunge. Instead of generating radial loads that bend the tool and accelerate spindle wear, it focuses forces axially on the spindle bearings. The cutter enables the machine to maintain high speeds and feeds straight to the bottom of deep cavities.

Take a Plunge

The robust plunge rougher combines a helical cutting edge to increase metal removal rates with inserts and body flutes designed to promote chip evacuation. Compared with standard inserts, the extra-thick inserts of the plunge cutter also are far better able to withstand high machining loads encountered in hardened materials.

The application specialists first suggested machining a five-inch diameter hole eight inches deep with a button cutter following a helically-interpolated toolpath. Starting at the periphery of the hole, the plunge cutter then opened the remaining pocket area in a little more than twelve hours - half the time previously required.

New concept tools also can improve the productivity of mold finishing cuts. When one shop used regrindable, HSS endmills to finish wear plate areas deep in a large mold, finishing time topped one hour and twenty minutes. To boost throughput and eliminate the cost of regrinding the HSS tools, a productivity team recommended a finishing long-edge cutter. The indexable long-edged finishing endmill uses ground inserts and a precision cutter body to achieve tight dimensional tolerances and a microfinish equal to HSS cutters. In addition, modern carbide cutting inserts enable the finishing cutter to sustain higher speeds and feeds for a machining time of just twenty minutes.

Solid Speed

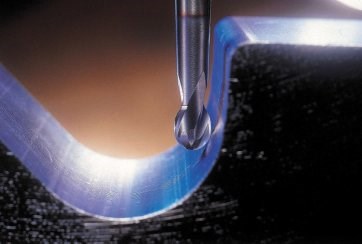

Solid carbide cutters are the tools of choice for many HSM finishing cuts in hardened steel molds. Cutters with reinforced cutting edges incorporate neutral or negative rake to mill materials up to 63 Rc. The thick core of the cutter also provides maximum bending stiffness to prevent deflection from high cutting forces. Even with stiff solid carbide tools, HSM finishing or super-finishing radial and/or axial depths-of-cut in hardened tool steels should not exceed 0.008 inch.

Though HSM emphasizes throughput, tool life remains important in finishing in cases which a tool change in mid-cut necessitates polishing for a uniform finish. Grade GC1610 solid carbide endmills outlast ordinary tools four or five to one in hardened alloy steels. They have a wear-resistant coating to sustain very sharp edges for optimum chip removal, good surface finish and fewer tool changes. These tools can increase productivity 30 to 50 percent compared with conventional solid carbide cutters.

High-speed, hard-part machining with modern solid carbide cutters also achieves EDM-quality finishes without slowly cutting graphite electrodes and burning cavities. In one application with steel hardened to 58 Rc, features that once took one-and-a-half hours to EDM were finished in just five minutes with solid endmills. A stable endmill in a holder permitted a spindle speed of 15,000 rpm. With a feed of 720 ipm and axial and radial depths-of-cut of just 0.0015 in., HSM slashed cycle time by 94 percent.

Hard Part Differences

Milling hardened molds takes an integrated approach to cutting tools, toolholders, machines and the milling process. Cutting tools and holders must provide exceptional rigidity and stability. Machine slides and workholding clamps and fixtures must be extra-strong. CNC machines and their software also must provide optimized cutting paths. Helical interpolation routines, for example, enable small machines with limited power to cut large holes in hardened stock. Remaining stock (REST) milling uses two identical tools following different toolpaths to semifinish mold cavities faster.

In addition to rigid machines and setups, moldmaking demands strong, rigid toolholders with low run-out for a smooth, accurate cut. Modular tooling, for example, uses a trilobed coupling to create an extremely precise and stable joint. The self-centering coupling provides a pretensioned joint interface that develops several tons of clamping force. The modular system also enables machine operators to replace tools quickly and return them to accurate cutting positions while enabling users to build tool assemblies of various lengths, which allows short to very long assemblies to suit the application.

Indexable and solid carbide endmills also require rigid, secure holders with high clamping force and minimal run-out. Precision power chucks, for example, provide twice the clamping force of shrink-fit holders and three times more than hydraulic chucks.

Milling inserts and solid tools can be vulnerable to dramatic temperature changes. For those reasons, hard mold milling should be performed dry, without expensive cutting fluid that can damage and shatter cutting tools with thermal shock. Machining hard materials nevertheless demands special attention to chip control to prevent tool breakage and to attain the best part finish. Without a flood of costly fluid to flush chips away, air-blast systems are recommended to keep chips away from the cutting zone.

Partners in Productivity

Machining data for milling hardened molds must be determined carefully to maximize productivity yet avoid excessive heat and edge wear. Replacing slow-cutting tools with longer-lived inserts or advanced solid cutters at conservative feeds and speeds is a costly mistake. Cutting data from tool manufacturers provides a starting point, but achieving the full benefit of high-speed, hard-mold machining requires insight into tools and processes.

For moldmakers, the benefits of high-speed, hard-part milling are significant, but the interactions between cutting tools, machines and hardened materials are complex. In high-speed and hard-part mold machining, some additional insight and technical assistance can make the most of new tooling solutions.

Related Content

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRead Next

Work Smart: Balancing Price and Productivity

Cutting tools are unique in their effect, as relatively small investments can result in tremendous cost reductions.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More