How Surface Treatments Keep Molds Operating Longer

Important tips and information about mold coatings to help you achieve the level of production that you and your customers desire.

There’s an awful lot to know these days about molding plastic and how to get the very best performance from the valuable tools you build or run. This guide has been written to provide important tips and information about mold coatings. After reading this, you should have a very good idea of what coatings—from the very traditional to the very latest—will help you to achieve the level of production you and your customers desire. After all, these tools are an investment and they need to be protected for the life of the products they mold.

The Key Role of Coatings

Before introducing you to the wide range of coatings on the market today (see Chart 1), it’s important to note the role coatings can play in an effective preventive maintenance (PM) program.

PM is really the key to protecting your tooling, your investment. Why? Because it saves time and money. Once you invest in a mold coating to improve tool performance, then a PM program is always a good idea to ensure you get the maximum benefit. These two steps should be a given in any shop.

Remember, no coating lasts forever, and producing substandard parts from a mold with a worn coating is no way to win customers and stay profitable. PM is probably the most cost-effective strategy you can put in place. The key is to educate your personnel on how mold coatings wear during production. Every coating is different, so it’s of benefit to have employees learn how to tell when the coating is showing deterioration, especially in high-wear areas such as gates and runners.

For example, wear in and around gate areas plated with hard chrome is the first sign that your mold needs servicing. How can you tell there is wear? The chrome coating is approximately 20 RC points harder than the base steel, so exposed steel will wear much faster than the coated surfaces surrounding it, causing a slight or pronounced edge or “step” on the surface.

Conversely, nickel will wear almost evenly, causing a kind of feathering effect, making it more difficult to recognize wear. A more identifiable difference will be the color because when nickel coating wears, it produces a shadow or halo effect on the steel. No step or edge will be evident. The steel also will have a more silver appearance compared to the somewhat tarnished look of the nickel coating.

This knowledge makes pulling a mold for maintenance before the coating wears through an ultra important aspect of a PM program. To miss important wear signals means more costly repairs and additional polishing expense.

Measuring Wear

A recommended tool for measuring the wear level of any coating is an electronic thickness gauge that uses a combination of magnetism and eddy current to accurately measure surface thickness. When the mold first arrives in your plant, take the time to measure the surface thickness—especially in high-wear areas—using this specialized tool. As you run production on the mold, occasionally pause to re-measure those areas. When you have determined that the finish is wearing to a critical level, pull the mold and send it out for maintenance.

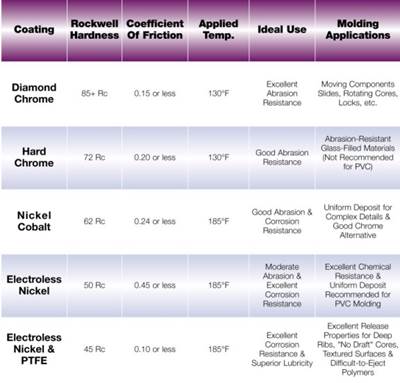

| Chart 1 | |||||

| Coating | Rockwell Hardness |

Coefficient Of Friction |

Applied Temp. | Ideal Use | Molding Applications |

| Diamond-Chrome | 85 + R.C. | 0.15 or less | 130 Deg. F | Excellent Abrasion Resistance |

Moving Components Slides, Rotating Cores,Locks, etc. |

| Hard Chrome QQ-C-320 |

72 R.C. | 0.20 or less | 130 Deg. F | Good Abrasion Resistance |

Abrasion Resistance Glass filled Materials (Not Recomended for PVC) |

| E.N. Boron-Nitride |

54 R.C. as plated 67 R.C. After H.T. |

0.05 or less | 185 Deg. F | Superior Lubricity & Excellent Abrasion |

Where Superior Release & High Wear or High Temperature are an Issue |

| Nickel-Cobalt | 62 R.C. | 0.24 or less | 185 Deg. F | Good Abrasion & Corrosion Resistance |

Uniform Deposit for Complex Details & Good Chrome Alternative |

| Electroless Nickel AMS-2404-C AMS-2405-B |

50 R.C. | 0.45 or less | 185 Deg. F | Moderate Abrasion & Excellent Corrosion Resistance |

Excellent Chemical Resistance & Uniform Deposit Recommended for PVC Molding |

| Nickel-P.T.F.E. | 45 R.C. | 0.10 or less | 185 Deg. F | Excellent Corrosion Resistance & Superior Lubricity |

Excellent Release Properties for Deep Ribs, “No Draft” Cores, Textured Surfaces & Difficult to Eject Polymers |

| Sulfamate Nickel QQ-N-290 |

40 R.C. | 0.45 or less | 140 Deg. F | Pitt Free Heavy Deposits |

Isolated Deposits for Dimensional Corrections |

| Engineered coatings and finishes. Chart courtesy of Bales Mold Service. | |||||

Part Counts

Be sure to record the measurements taken with the thickness gauge and use the notes to create a history of maintenance requirements for the tool. A cycle counter installed on the mold will allow your tooling engineer to record wear levels as compared to piece part counts, thereby doubling the effectiveness of your PM program. Part counts are a great way to determine maintenance needs, especially with high-volume molding projects.

From the very first time you run the mold, keep an accurate piece count until it is ready for its first maintenance work. Use that count as a gauge for when the next maintenance is due. Because you know approximately when the mold will be ready to be refurbished, you can arrange the service in advance with your coating vendor. This not only gives him ample time to schedule your mold maintenance, but it also allows you to optimize the use of the mold and the machine that’s running it.

Coating Challenges

Even today, there are those who question the benefits of using fancy—sometimes more expensive—coatings to prolong tooling life or enhance performance. To some, the tried and true hard chrome or electroless nickel are all they’ll ever need to accomplish those goals. But we all know that today’s engineered plastic materials can be pretty rough on injection molds.

Challenges to mold maintenance extend beyond glass- and mineral-fillers to include rice hulls, wood fibers, metal powders, flame retardants and other additives—not to mention the resins themselves. In addition, outgassing and moisture acidity often accompany abrasive wear, taking an even bigger toll on expensive tooling.

In addition, growing complexity in mold design involves tinier, more intricate flow passages and more frequent use of moving cores and slides. All of these circumstances have prompted the development of a wider variety of mold coatings that can keep molds operating longer between repairs.

New Coating Science

If you are molding highly intricate parts using glass-filled materials, you might think using hard chrome will be sufficient because it is a classic, reliable way to protect your mold from both corrosion and abrasion. However, hard chrome, for all its benefits, does not tend to plate uniformly in detailed areas like ribs and bosses. There is a newer solution—a nickel-cobalt alloy coating that can overcome that limitation.

Nickel Cobalt

Nickel-cobalt can be an economical alternative to hard chrome. Hard chrome requires construction of a conforming anode to coat the mold. The more detail in the mold, the more time it takes to build the anode and the more expensive the process becomes. This nickel-cobalt alloy coating requires no anode, and because of its electroless properties, it plates much more uniformly.

The cobalt gives it good abrasion resistance, but its hardness is 62 RC, 10 points lower than hard chrome. Is it worth paying extra for hard chrome’s superior wear protection? You have to consider the material being run in the mold. What’s the percentage of glass? Is corrosion a greater concern than abrasion?

Diamond Chrome

Hard chrome and a nickel-cobalt alloy coating offer two very good solutions for abrasion resistance, but for very high-wear conditions, an even newer product called diamond-chrome offers exceptional protection.

It has an RC rating greater than 85 and is a chromium-matrix composite coating with a dispersion of nanometer-size, spherical diamond particles. Since diamonds are unmatched for hardness, this coating offers protection beyond the norm. Though their Rockwell ratings are comparable, diamond-chrome outperforms titanium nitride (TiN) coating because it won’t compromise the dimensional integrity of the plated tool. The difference is that it is applied at only about 130oF while TiN requires application temperatures of 800oF or higher.

Diamond-chrome can plate prehardened, heat-treated or nitrided steel and other base materials such as aluminum, beryllium-copper, brass and stainless steel. Recommended uses include cores, cavities, slides, ejector sleeves, and rotating and unscrewing cores. Its anti-galling properties are advantageous on moving cores and slides.

Diamond-chrome also is very strippable and has no adverse effect on the base material, saving time and money when maintenance is needed. TiN is strippable as well, but it can take up to several days to remove with a peroxide-based solution. Diamond-chrome can be stripped in minutes using reverse electrolysis in a caustic solution.

In addition, diamond-chrome can be deposited at any controlled thickness from 20 millionths of an inch to 0.001 in. TiN is generally only applied in thin deposits of a few millionths of an inch. Diamond-chrome can coat complex details, while TiN has very limited coverage of complex details. While TiN is very lubricious, with a coefficient of friction (COF) of 0.4 (against steel), diamond-chrome has a COF of 0.15—nearly three times more lubricious.

Nickel-Boron Nitride

When it comes to molders’ needs for a specialty coating that offers excellent release properties and high resistance to wear, heat, and corrosion, an electroless nickel-phosphorus matrix containing boron nitride particles should be considered.

It has a very low COF (0.05 against steel) and an RC hardness of 54, which can be increased to 67 RC after heat treating—a unique characteristic. Nickel-boron nitride can be applied to any substrate at only 185oF and can be easily stripped without compromising the base material. Though it is approximately 20 percent more expensive than nickel-PTFE, this coating will outperform nickel-PTFE at up to 1250oF, which far surpasses the 500oF maximum limit for all PTFE-based coatings.

Because applying nickel-boron nitride is an autocatalytic process, it requires no anode, therefore saving time and money. In addition, it will not compromise thermal conductivity of the mold. Applications include unscrewing cores for closures, where reduced cycle times are essential.

Where lubricity is needed for better release from deep ribs, zero-draft cores, textured surfaces and “sticky” polymers, a nickel-PTFE composite will greatly improve part release and enhance resin flow by as much as 4 to 8 percent for shorter cycle times. COF is 0.10 against steel.

It should be noted that applying pure PTFE to the mold adds high lubricity, but only a very short-term benefit. PTFE by itself has no hardness, so it won’t last. But a dispersion of 25 percent PTFE by volume in a co-deposit with nickel results in 45 RC hardness for added wear and corrosion protection.

Tried and True

Despite the new coating science, we cannot throw out the old, reliable coatings such as like hard chrome or electroless nickel just yet. There’s no question that they still have their uses.

Hard Chrome

For example, hard chrome’s top advantage is that it has a hardness of 72 Rockwell C (RC) and is applied at the low temperature of 130oF. When applied in its purest form, it allows you to achieve any SPI finish on your tooling.

Hard chrome is often a good choice for electrical circuit-breaker molds since they use materials containing as much as 40 percent glass. To help combat erosion and prevent severely damaging gates and surrounding mold areas, it is usually recommend to use a high-diamond polish, followed by a hard-chrome coating of 0.0003 to 0.0005 inches for added protection.

The downside can be cost, since chrome plating is limited to areas accessible by an anode. If your mold has complex details, it could require extra conforming anode construction and that adds time and expense to the project. Another possible drawback is chrome’s environmental impact—chromium is a carcinogen. Some companies are attempting to develop better, cleaner alternatives, but so far nothing matches hard chrome’s benefits from a tooling perspective.

Electroless Nickel

Like hard chrome, electroless nickel has been used successfully for years, particularly to protect molds where corrosive off-gassing is created by materials such as PVC or halogenated fire retardants. It is not uncommon to see such resins produce an orange rust, corroding the unprotected mold almost right before your eyes. Products molded of such materials for the electronic or medical industry often cannot tolerate the presence of any oxidation byproducts.

Electroless nickel does an excellent job of resisting oxidation because it plates very uniformly in thin deposits of 0.0002 to 0.0003 inches. Even in tight areas of detailed parts, electroless nickel at 50 RC hardness is ideal for corrosion protection. It can be deposited in very accurate thicknesses of 0.002 to 0.003 inches and can be ground or EDM’ed. Thus, electroless nickel often is used for dimensional build-ups under flash chrome and for enlarging threaded cores and inserts or precisely sizing cavities. It also works very well on entire mold bases, A and B plates, ejector-base housings, pin plates and pillar supports, providing years of low-maintenance, rust-free operation.

Know Your Mold Finishes

Before determining what coating to use—if one is needed—the mold finish must be taken into account because, as noted earlier, certain finishes may actually increase the need for a mold coating, and some combinations work extremely well together improving lubricity and release properties.

There are four standard SPI finishes: diamond, stone, paper and blast. Each gives the molding surface a different appearance, from a glossy, mirror-like surface (A-1 Diamond) to a fairly rough, gritty texture (from blasting with glass beads or aluminum oxide). Each of the four finishes has three grades as well.

Diamond

The A-1 Diamond finish is the most perfect finish available, which means it has the lowest RA value (roughness average). There are no high or low ridges. For example, a paper scratch on steel can rate a 2 to 4 RA finish, whereas an A-1 Diamond is lens-quality smoothness, generally 1 RA or less. Roughness is almost immeasurable.

But a number of plastic materials tend to stick like glue to the flawless, mirror-like finish, making such perfect smoothness almost detrimental in many molding applications. One good example is molding polystyrene on a polished straight-wall core with 1d or less draft. Streak or drag lines can appear on the parts. This can be solved by flash-chrome plating the core, which creates a surface with micro-cracks. Impregnating those cracks with PTFE and then re-establishing the A-1 Diamond finish solves the problem in more than 95 percent of cases.

Thin-wall container molding adds another dimension to the use of a diamond finish. Molders of sour cream, yogurt and cottage cheese containers find their products are more attractive to the customer if they have a slight sheen. To obtain that effect, these parts require a high-diamond polish with a slightly interrupted gloss adjustment so that the slight sheen will occur. This finish adjustment also allows for much better release of the parts.

In thin-wall molding applications such as these, a light bead-blast finish is applied—just enough to very slightly interrupt the flawless A-2 Diamond surface. The surface is buffed again, leaving just a bit of almost invisible stipple. This finish plus a coating of nickel-PTFE will greatly improve part release and enhance mold filling.

Phenolics and other thermosets almost demand a perfect polish and work extraordinarily well with a diamond finish. Combine that with a hard, protective coating like chrome or diamond-chrome, and you will strengthen the mold’s surface and optimize release.

Again, using a topical PTFE coating would be of minimal benefit because it will not last long. Successful application of straight PTFE depends on having a sufficient grain structure in the mold finish to hold onto the coating. Since molding thermosets requires a perfect finish on the tool, PTFE by itself will have limited adhesion to the surface and therefore will fail relatively quickly.

Texture and Release

There are many textured surfaces today, including faux leather for automobile dashboards, woodgrains, geometric patterns and stipple patterns found on pagers, cell phones and computer components. A plated mold coating is often essential to obtaining a textured surface with adequate lubricity.

Textured surfaces require protection. The peaks of the textured surfaces are the first areas of mold detail to experience wear, making it very important to check the mold periodically with a profilometer to measure grain depth and peak counts. Mold coatings help decrease the frequency of repairs and refurbishment by maintaining the integrity of the textured surface.

If a diamond finish presents release problems, a blast finish can be the answer—particularly when molding textured parts using materials such as silicone rubber, flexible PVC, TPEs and some soft polypropylenes. These products tend to cling to a polished finish, but breaking up the surface with a light blasting improves release. Add a coating of nickel-PTFE and you get even better release.

Hard chrome and electroless nickel plating will help protect textured surfaces, as will a nickel-cobalt coating. Unlike hard chrome, electroless nickel-cobalt plates uniformly, which makes it ideal for very detailed molds with deep ribs and bosses. It combines the corrosion protection and lubricity of electroless nickel with the strength of cobalt.

Summary

If you’re looking for enhanced performance in your molds, the proper combination of surface treatment and finish can provide additional benefit by extending production times between preventive maintenance. Your coatings vendor can be a valuable resource for educating your personnel on how coatings you use will wear over time, as well as a way to reduce downtime and cut costs.

Related Content

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Tough Coatings Control and Extend Mold Life

Moldmakers can solve tough productivity problems by applying next-generation coatings.

Read MoreBulked-Up Coatings Increase Mold Productivity

Which choice is the best coating - one that provides long production life and minimal maintenance needs.

Read More