Fun Friday: A Moldmaker’s Passion for Classic Cars

That AMBA Chicago BBQ stirred up some interesting history when it comes to classic cars and the moldmakers who own(ed) them – especially for Chuck Klingler of Janler Corp.

Share

Read Next

This blog is kind of a “part two” to my Fun Friday blog of July 28 titled “Moldmakers and Their Toys.” That AMBA Chicago BBQ stirred up some interesting history when it comes to classic cars and the moldmakers who own(ed) them – especially for Chuck Klingler of Janler Corp.

Chuck’s father, the late Josef Klingler, founder of Janler, shared his passion for classic cars with Chuck, who shared some memories with me. “My dad’s collection was extensive for sure. We partnered on several cars, and at the high point, his, mine and ours added up to over 50 automobiles,” he says.

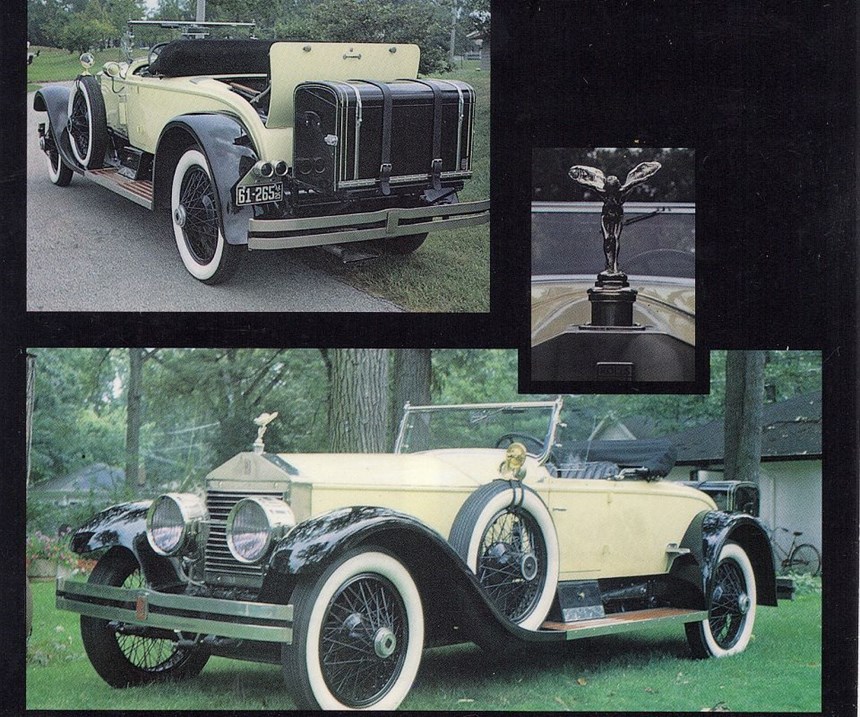

The collection Joe and Chuck accumulated ranged from a 1926 Rolls-Royce Picadilly Roadster that was originally owned by Howard Hughes (check out one of the images, above) to late-model Mercedes high-speed cruisers. “We had a full collection of Mercedes Benz,” Chuck told me. “All were post World War II, and I think we had 18 of them at one time.”

We partnered on several cars, and at the high point, his, mine and ours added up to over 50 automobiles.

Chuck shared a page from a magazine called The DuPont Showcase which featured the Rolls-Royce. The caption reads as follows:

“This superb Roadster was purchased new by Howard Hughes on November 5, 1925. Mr. Hughes had a penchant for the finer things in life, and this Picadilly Roadster met his demands for excellence. This particular automobile #S135MK was built by Merrimac and its series was the first left hand drive off the blocks. Finished in yellow over black, it has only 14,000 miles. Complete with a standard 3-speed transmission and sporting a polished engine with dual ignition. This beautiful Roadster has been completely restored to mint condition and is part of the Josef Klingler Collection in Chicago, Illinois.”

It's always so interesting to learn about a classic car’s provenance, and this one does not disappoint! Unfortunately, Chuck says all the Rolls-Royces from his dad’s collection are gone. But Chuck does still have a classic 1949 Triumph Roadster (also pictured above) that Joe bought in 1953. “He was a consummate collector,” Chuck says. “It was his first ‘sports car.’ I worked on it and drove it to high school—as well as on a couple of dates. After being stored/parked for over 20 years, I restored the Triumph in the 90’s for my dad, as he retired from Janler. I bought it from him about five years ago, when he felt he could no longer drive it safely. The car is very special and I do drive it, and I will never sell it.” (Understandable!)

My dad never wanted to sell any of the cars, but we ran out of storage!

I asked him if his father ever collected Porsches. He answered, “We added up almost 200 cars that passed through our hands, but believe or not, we never owned a Porsche! But we had several friends that owned them, and we did do some work on their cars in our restoration shop. My dad never wanted to sell any of the cars, but we ran out of storage!”

Chuck says he has lots of fond memories revolving around his father and their shared passion for the automobile, plus “a thousand great stories!!” I plan to hear as many of those stories as I can someday. Cheers to moldmakers and their toys! Write to me about yours!

Related Content

Five-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.

Read MoreCAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreHybrid Milling/Drilling Machine Reduces Total Mold Machining Time

MSI Mold Builders now squares, plus drills and taps eye-bolt holes on 50% of its tools in a single setup using a five-axis milling/drilling center with a universal spindle.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More