Expanding Aluminum’s Potential

Hard-coating provides a number of benefits that make aluminum tooling an attractive alternative to steel.

Aluminum tooling has a variety of natural characteristics that can benefit the injection molding process. For example, aluminum’s faster cutting and overall manufacturing times allow for greater throughput efficiencies, its high thermal conductivity enables it to be processed more easily, and it is very strong, to name a few of its advantages. While these characteristics help to yield faster cycle times and reduced waste, hard-coating an aluminum mold with nickel boron or electroless nickel can further improve its durability and its ability to produce plastic parts with Class A surface finishes when high volumes are required.

The cost of hard-coating an aluminum mold depends on the type of hard coating and the size of the mold. It typically adds just a fraction to the overall cost of the tooling, similar to the cost of a texture or grain application.

Hard-coating also adds only a minimal amount of depth to the tooling. For example, electroless nickel plating is an autocatalytic process that plates evenly once the part is submerged in the tank, without using an electrical current. The plating thickness can be held in tight tolerance with a recommended 0.0002 to 0.0003 inch per side. Typically, an application of as much as 0.0005 inch after part sampling validation is used to account for any potential mold adjustments, such as a tight part tolerance.

The primary benefits of hard-coating are protection, surface finish, lubricity, durability and return on investment, which are further explained here.

Protection

Hard-coating protects the mold integrity for the life of the tool by adding additional hardness and corrosion resistance. Aluminum has a low hardness level, close to 18 HRC, and applying any nickel-based coating will bring that hardness level to 45 HRC or higher. Nickel coatings also provide a layer of corrosion resistance to further protect the molding surface. Chrome coatings are often considered for added corrosion resistance, but they do not adhere uniformly and leave microscopic areas uncoated in which corrosion can begin. Electroless nickel seals and protects the surface better.

When molding abrasive resins such as glass-filled nylons, a hard coating with a hardness level that is higher than that of the mold’s base material (aluminum) will protect the mold’s surface from excessive wear. The abrasive resin will wear away the harder coating on the surface of the mold before it reaches the base material. Unprotected, the aluminum would erode, damaging mold details, removing texture and rounding sharp edges. Nickel coating can be applied as thick as 0.0006 inch, and can be easily stripped and reapplied without any damage to the aluminum base material. The whole part is simply placed into a stripping solution and removed when the coating has been dissolved.

When part revisions or mold repair requiring either welding or re-cutting of the aluminum are needed, the coating must first be stripped and then reapplied after the welding or recutting is completed. Stripping will return the part to just the base material. After any changes or repairs are completed, the coating is reapplied to bring the mold back to optimum working condition. Welding over the plating is not recommended because the plating’s “slip” or lubricity may prevent the weld from properly adhering.

Surface Finish

Aluminum is a soft and porous base material. This presents a challenge when the mold must be polished to a Class A surface finish, which is required, for example, for producing optical components such as clear lenses, prisms and light pipes. Any mold imperfections will reproduce in these optical components.

Hard-coating can help the moldmaker achieve a Class A surface finish in aluminum, if it is done properly. For example, an electroless nickel surface coating can enable the aluminum base material to be polished with superior results, but if the hard coating is not applied to a uniform depth, it will result in a poor finish. An experienced polisher can polish the plating, but the ability to do so without the plating wearing off or without breaking through the plating takes a long time to master.

Texture and grains on a mold surface can also be protected with a hard-coat process. The coating is harder than the base material, so it can withstand an abrasive molding material, like the glass-filled nylon mentioned earlier. A minimal amount of coating (0.0002 to 0.0003 inch) will cover the texture without filling it in and protect the peaks and valleys from wear, providing more consistent results between the first and the last parts run (see Figure 1).

Lubricity

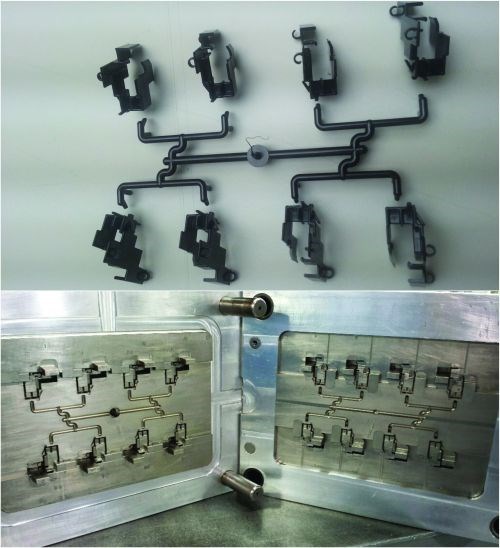

Nickel boron hard-coating is often used on aluminum molds that have complex geometries or minimal draft allowances that can interfere with part release. Such geometries include deep ribs or thin-wall conditions that assist in part processing and ejection from the mold surfaces. These types of geometries can be difficult to fill with resin, and the pressure exerted against the mold by the resin can make it difficult for the part to be released from the mold.

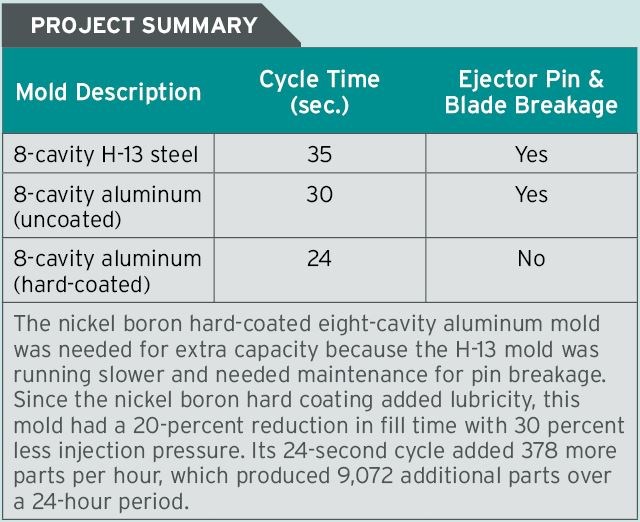

Nickel coatings are applied using an electroless process in which the whole part is submerged in the plating bath. Nickel boron is co-deposited (the electroless nickel and boron are in the same bath and applied at the same time) for a uniform thickness, providing high lubricity and part release from the mold. Electroless nickel has a coefficient of friction of 0.45 or less, while the nickel boron coating has a coefficient of 0.05 or less. The lower the coefficient of friction, the less friction between mold and part, and the easier the release of the part (see Figure 2).

Durability

High part volumes such as in the hundreds of thousands for parts molded from abrasive resins, and in the millions for parts made from non-abrasive resins, take a toll on mold durability, and hard-coating can protect the mold surface. It’s usually necessary to apply the hard coating after part approval but before production startup in order to help keep shutoffs and any wear areas on the mold clean and sharp. Even a short run, especially with a abrasive material, can alter tool dimensions. Plating the tool early helps avoid the need for buildup and repair later.

Again, nickel coatings raise the hardness level of aluminum to 45-54 HRC, which results in increased wearability of aluminum molds. Coatings also can serve as great wear indicators. Once it is applied, the actual buildup of the hard coating can be measured, documented and monitored as part of the preventative maintenance performed after production runs. When the base material wears through the nickel coating, it is time to strip and recoat the mold (see Figure 3).

Return on Investment

Using an aluminum mold to its full life expectancy is a sure way to achieve a return on investment of that tool, and hard-coating can help (see Figure 4). Too often, the mold is used to produce only a few hundred or thousand parts, and then it sits on the shelf collecting dust. Molds made from today’s aluminum grades and hard-coated can start the ROI at the very beginning of the project.

Summary

Aluminum has and will continue to be an attractive alternative to steel for tooling, and hard-coating can make it even more attractive. To select the appropriate hard coating for a specific aluminum alloy, consider the resin that will be used for molding, the part’s life expectancy, part geometry challenges for proper fill or ejection, and surface finish requirements. Nickel boron and electroless nickel hard coatings can enhance the life of an aluminum mold, improve surface finish, provide protection from corrosive resins, assist with difficult part geometries that require additional lubricity and decrease overall molding cycle time. Aluminum may not be the answer for all applications, but hard-coating expands its potential.

Related Content

Micro-Milled Steel Plate Cuts Mold Build Times by 10-15%

Steel 21 emphasizes its tighter tolerances, improved surface quality and speed of processing using the patented “21 Micro Milling” process.

Read MoreQualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

Read MoreVIDEO: Innovative Materials Boost Mold Efficiency

Advancements in metal 3D printing and stainless steel optimize mold building for diverse, high-demand industries.

Read MoreWhat You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

Read MoreRead Next

Let’s Be Clear About Aluminum

Within the injection molding industry, a negative perception of aluminum for anything but prototype plastic parts persists, despite aluminum tooling being able to produce and run almost any resin that steel can, as well as produce millions of shots with unfilled resin with uniform results.

Read MorePlating and Maintaining Textured Surfaces

Communication with your texturing and plating sources is key to properly maintaining the mold surface.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More