Eliminating Seams

A zero-parting-line process requires collaboration among the toolmaker, its texturization provider and the OEM.

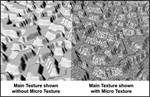

OEMs today want fewer parts to assemble, which increases the demand for single parts with more complex shapes. These complex parts often require slides or lifters to facilitate removal from the mold, and seams from these different mold components can appear in areas on the parts that are highly visible. This conflicts with prevailing design intent whereby parting-line seams should not interrupt the A surface of the part, triggering the development of a zero-parting-line process to minimize or eliminate these seams.

The process for achieving zero parting line does not initially include the texture process. The tooling work for zero parting line is done by the texture source before the texture is applied. It requires collaboration among the toolmaker, its texturization provider and the OEM. The process should begin with a mold design review, as the design of the slide to cavity or core to cavity is critical to the success of this process.

Here are recommendations and steps for matching a slide to a cavity in such a zero-parting-line process (a core or lifter could also be matched):

1. The slide must be bolted to the cavity throughout the texturing process. It is critical to address this cavity-to-slide fixture in the initial mold design.

2. The cavity and the slide must be made of the same type of steel, and the hardness level of each must be within 2 HRC of the other.

3. A trained zero parting line technician should assess the access to the seam area at tool design review to assure that the work in this area can take place unimpeded.

4. Once these bolt-on and access requirements are met, the zero-parting-line process may be achieved. The process includes peening and polishing.

5. The tool shop must deliver the best possible match between cavity and slide/lifter, as per the OEM standard (20 microns/0.001 inch maximum offset, with no flash).

6. Matching of the slide/lifter in the cavity pocket must be securely bolted, without movement.

7. The match along the edge of the parting line must be absolute for a minimum of 1 mm from the parting line.

8. The last-off sample parts from each cavity must be supplied to the texture house without requiring additional work after last-off shots. These parts will set the expectation for the OEM as to how much of the seam will be hidden on the final parts.

9. The tool shop should properly bolt and securely lock the slide/lifter in the cavity pocket before shipping the mold to the texture house.

10. The texture house will “touch up” the cavity/slide parting-line match before applying the texture and through each etch stage, ensuring a perfect match condition.

11. After zero-parting-line work, molded samples are then produced in the tool without texture and again with texture.

12. Final gloss is applied with the slide/insert bolted in place.

Related Content

-

Understanding Diamond Compounds

Diamond compounds, with their varied grades, colors and base options, provide a comprehensive solution for mold builders in need of precise and superior polishing across diverse materials and applications.

-

Line Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

-

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.