Dodging the Skills Gap in CNC Programming

Sometimes the search for fresh, new and skilled employees is like a game of dodgeball.

A little ingenuity and adaptable technology helped one company bridge a CNC skills gap.

Sometimes the search for fresh, new and skilled employees is like a game of dodgeball. You throw the ball (your recruitment efforts) out into the arena (your geographical location, probably including local schools and junior colleges) to see if anything hits. If you make a point, a new and promising employee is hired who can hit the ground running. But often, as is the case with one company that needed CNC machinists who could get to work quickly, you miss. It’s a game called “skills gap dodgeball” that’s still predominant across North America.

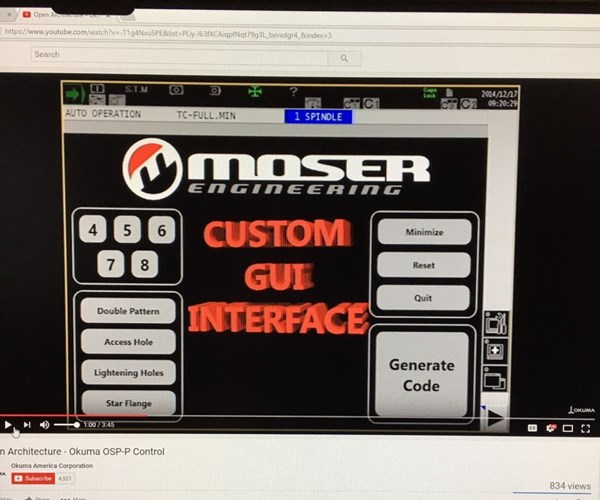

The company I’m referring to is called Moser Engineering, a manufacturer of performance axles and aftermarket rear end components for the auto racing industry, located in Portland, Indiana. MMT received a press release about Moser from Okuma America Corp., the U.S.-based arm of the maker of machine tools based in Japan. According to the Okuma press release, Moser had operators without a lot of CNC machining experience, and they needed to find a way to make the user process on their machine tools as easy as possible. “They wanted a process that eliminated human errors that came about when programming manually at the control,” Brad Klippstein, Controls Product specialist, says. Gosiger, an Okuma distributor, worked with Moser to help bridge the skills gap in CNC machining by using some good, old-fashioned engineering ingenuity. They took Okuma’s customizable CNC control and created a GUI interface in order to take setup and programming errors out of the CNC operators’ hands and, instead, provide them with easy part programming guides.

“Creating programs in under 30 seconds and hitting ‘cycle start’ allows Moser’s operators to not worry about storing thousands of programs or trying to call up the correct one. They also do not need to worry about interference issues since it is taken care of by the macro programs,” Klippstein says. “This GUI interface eliminates the need to worry about common problems when programming or troubleshooting at the machine. This solution was made by Gosiger and Moser Engineering on our open architecture OSP controls.”

Okuma actually published a video on YouTube about how they helped Moser Engineering solve its skills-gap issue, and you can find it here. These kinds of stories remind us about the level of engineering expertise that exists in our industry; and it also provides a wonderful example of the creativity and problem-solving skills.

Related Content

-

What is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

-

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

-

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.