Defining What Makes High-Speed Machining Different

A look at what true high speed and true high precision can produce, as well as what makes high-speed machining different from traditional milling.

Not many would argue that mold machining is an art form, as well as a masterful skill since it produces beautiful surface finishes. PJ Naughton, sales manager for Jingdiao North America, talks about what true high speed and true high precision can produce in this video from last year’s Amerimold.

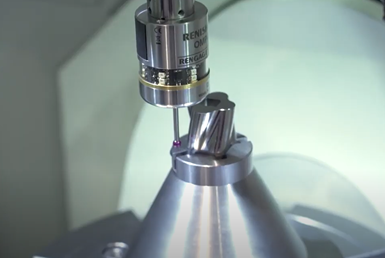

PJ Naughton: At Jingdiao, we define high speed machining as a spindle speed of anywhere from 20, 30, up to 40000 rpm, also with the axis speed and the hundreds of inches per minute feed rate. What makes high speed machining different from traditional milling is you're only taking off small amounts of material at a very high feed rate.

So it's very accurate, but it's not like you're hogging out lots of material with high speed machining, and with the cutting tools out with high speed machining, they're very tiny. Some cutting tools go down to .002 thousand diameter. You're not really moving a lot of material, but it's moving fast and it's very precise. Before high speed machining came around, a mold shop would have to take up a part, rough it out in the soft state and go ahead, put it back in the heat treat. Put it back into a sinker EDM and do the semi finish and the detail. With high speed machining, you could actually rough it out in the soft state, but you could put it on the machine after heat treat, and do your finishing and fine finishing on the mill.

In this case here, many times you could almost eliminate any sort of need for sinker EDM, as well as reduce the amount of hand polishing reducing the number of setups. In many cases, you could eliminate the need to make a graphite electrode. A mold maker should be looking at a high speed mill that was designed and built for high speed machining, not a standard mill that was converted to a high speed mill. The machine has to be built rigid enough to withstand the forces of the high speed mill to avoid any sort of tool vibration.

Additionally, you've got to have tool wear monitoring device on there. You've got to have the right environment. You can't have an environment where the temperature fluctuates between 5 to 10 degrees. It has to be a stable environment. You also got to have regular maintenance on the machine and a solid CAM system that is designed for a high speed machining.

Related Content

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.