Cutting Tool Orders Poised for Growth in 2021

The annual rate of contraction in cutting tool orders has nearly bottomed. And, based on trends in the Gardner Business Index and macroeconomic manufacturing data, cutting tool orders should see double-digit growth by year-end.

In December 2020, real cutting tool orders were $157.3 million, contracting 17.1% from December 2019. However, this was the slowest rate of contraction since March 2020. December was the 22nd consecutive month of month-over-month contraction, but these same figures clearly show that the contraction is slowing.

The annual rate of change contracted at an accelerating rate for the 15th month. The annual rate of contraction was 22.6%, which was the fastest rate of annual contraction since the data was made public. The annual rate of contraction will likely accelerate a little through the March data release. Near the end of the first quarter, the annual rate of contraction should begin decelerating.

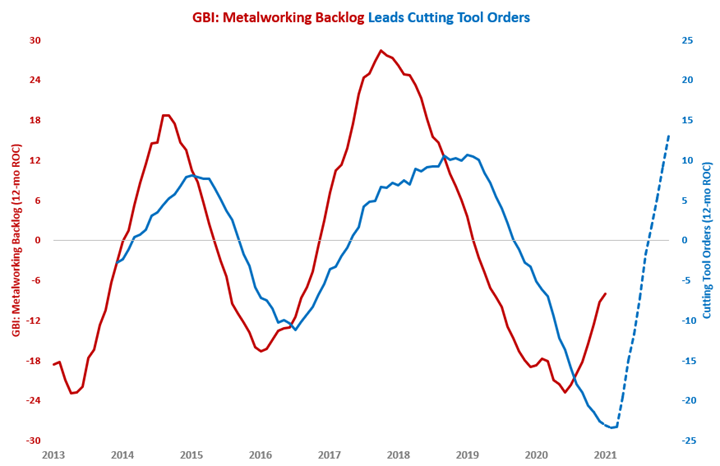

The GBI: Metalworking is a good leading indicator of cutting tool orders and leads cutting tool orders by seven to 10 months. In January, the index was above 50 for the fourth month in a row and the month-over-month rate of change in the index grew for the sixth consecutive month. The annual rate of contraction decelerated for the seventh straight month, indicating that the annual rate of contraction in cutting tool orders should bottom in the first quarter of 2021.

On the chart below, the dotted blue line represents the possible recovery in cutting tool orders. The forecast calls for cutting tool orders to grow by 13% in 2021 compared with 2020. The rate of recovery is faster (or steeper) than the previous two growth cycles for cutting tool orders because of the comparison in 2021 to periods of economic lockdown in 2020. This projection is relatively modest when compared with actual levels of historic cutting tool orders. One reason for this is that supply chain disruption may slow the manufacturing recovery.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.JPG;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)