Competitive Balance in Moldmaking

A Windsor moldmaker employs new strategies and software to stay ahead of the competition.

In 1975, Ron Kellenberger, Ray Bendig and Rick Janisse rented twenty-five hundred-square feet of shop space and founded Cavalier Tool & Manufacturing in Windsor, Ontario. Today, the maker of medium and large molds for a wide range of customers employs 110 in two buildings covering more than fifty-thousand square feet.

Cavalier makes molds used in a wide variety of consumer products as well as automotive applications, including injection, structural foam, die cast, blow molds, prototype or compression molds. The company is committed to designing and building a quality mold, on time, at a competitive price.

As Cavalier has grown, moldmaking has changed. "A lot of owners will say it's gone from fun to hard work," Janisse says, "but I still enjoy what I'm doing." It's clear, however, that increased domestic and overseas competition, as well as tighter delivery requirements, have made the business tougher. "The only way to be competitive in this market," Janisse says, "is to stay up on the new technologies."

Applied Technologies

To meet competition and fill the needs of its customers, Cavalier combines new technology with a wide array of new and veteran equipment.

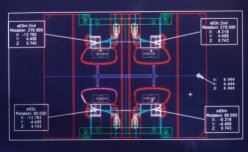

"We've got brand new machines as well as older ones," Janisse says. Presently, the company's mold machining equipment includes twelve CNC vertical machining centers as well as a ninety-six-inch vertical lathe, boring mills and a gundrill. The smallest machining center has a copy area of 18" by 42" while the largest machine can handle work 60" high by 67" wide and 130" long weighing up to fifty tons. The shop most recently added a high-speed, large-capacity Brute vertical machining center. All the machines' CNC controllers are networked with the shop's CAM department. In addition to its machining capabilities, Cavalier uses state-of-the-art, CNC-controlled orbital and wire EDM machines to produce fine mold details.

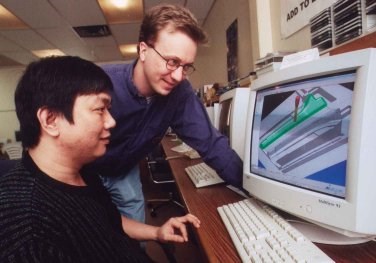

To maximize productivity, says CNC programmer Ed Mueller, Cavalier tailors machining strategies to individual machines. "The older, larger machines are more rigid and you can take a larger pick (DOC), but you have to go to slower feedrates," he says, "On the newer, more compact machines, we take a smaller pick and increase the feedrate." Mueller programs the cutting paths with PowerMILL software from Delcam International (Windsor, Ontario). On the higher-speed machines, Mueller says, PowerMILL offers great control over links and leads, permits blending cuts and executes corners in ways that assure gouge-free machining.

Lights Out

The toolpaths for some of Cavalier's larger molds require as long as twenty-four hours to machine. "The volume of metal removed determines that the cutting time will be long," Mueller says. To maximize machine use and meet customer deadlines, he explains that the goal is to achieve lights-out machining.

Cavalier employs a number of machining strategies aimed at expediting unattended operation. For example, to protect the workpiece and cutting tool when running unattended, Mueller says, "We try to climb mill instead of milling back and forth. It takes a little longer because the mill has to rapid back, but you have less chance of gouging than in conventional milling, where the tool pulls into the steel. Climb milling is a lot better for lights-out machining."

When possible Cavalier employs PowerMILL's constant Z or profiling strategy, as opposed to bumping or raster methods, because constant Z equalizes cutting forces on the tool. CNC programmer Tin Nguyen says, "With bumping, you're not sure how much the tool is removing on the bottom or the sides; it can be heavy cutting. With profiling, it's constant."

Mueller says PowerMILL is a key tool in achieving the goal of lights-out machining. He says that the faith they have in the program enables shop personnel to make sure the machine has a good cutter in there and let it go. "We let it run and run," he says.

Mueller says he's used PowerMILL and earlier Delcam CAM programs for more than a decade, and has seen the software evolve and improve. As with any technology, the development path has not been entirely direct or smooth. Mueller says he has suggested changes and pointed out "bugs" that Delcam quickly corrected. "They listen very well to us," Mueller says. Delcam Windsor area sales manager, Mark Forth, says he's happy to get input of any form from those who actually use PowerMILL. "We continually try and find areas where the software can be improved," he explains.

Electrode Production

Despite the precision and speed of present-day machining, EDM remains an essential tool in achieving fine mold details. Cavalier uses state-of-the-art CNC orbital and wire EDM machines. It is completely self-sufficient in EDM electrode design and manufacture.

Programmer Steve Glendinning says, "We have a CNC-controlled ONA EDM sinker that allows us to burn along a vector and do three burns in one setup. We have it set up for lights out machining, so we can set it up to burn for an entire weekend. We do the same thing with our CNC machining of electrodes. We set up four or five electrodes on the machine, pat it on the head and kiss it goodbye. The operator is needed only to change the electrodes, key in the correct programs to spool to the CNC control, hit the green button and walk away."

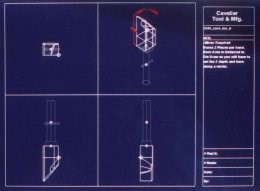

Glendinning uses the PS-Electrode module of Delcam's PowerSHAPE software to create the electronic files from which electrodes are made. He brings an IGES file from Cavalier's CAD department into PowerSHAPE, which can automatically generate an electrode through its Electrode Wizard. A series of forms in the Wizard enable Glendinning to define the region where the electrode will be needed, generate transition surfaces from the electrode's contact area and select a suitable blank from which the electrode can be machined.

When the electrode is complete, Glendinning appreciates that the PS-Electrode automatically produces electrode drawings and location sheets. "When you pull the electrode out, the PS-Electrode automatically and immediately generates the drawings and location sheets," he says. Previously, making the sheets consumed much more time. "I'd have to generate each individual electrode, then make an individual location drawing for it, make a separate setup sheet, and print that out. In terms of time, this way it's already done, for free," he says.

While Cavalier cuts most of its electrodes on a CNC machining center, in the interest of efficiency, the shop does hand-grind features or the entirety of some electrodes. Glendenning says, "We do a combination of the two. Sometimes it's easier to partially cut an electrode on the CNC, then grind the draft on it."

To handle both CNC-cut and hand-ground electrodes, Glendinning created his own custom setup sheets. "You can set them up any way you want," he explains. "In fact, I'm not using the standard sheet, which has only one, isometric view. I created my own sheets that work better for us. I wanted four views: front, top, regular third angle projection plus the isometric view. Some people only want an isometric view, because they are doing only CNC cut electrodes, and not any ground ones."

He continues, "I have configured my setup sheets so we can use the information not only for mounted, CNC-cut electrodes, but also for electrodes that will be hand ground. I can go in and put dimensions on the setup sheet so we can hand grind the electrodes. That way, if we want to make a quick rib we can grind it rather than use CNC time."

Glendinning says the PS-Electrode also offers the flexibility of easily moving in and out of the electrode Wizard. "If it's not a fully enclosed electrode, for example, where it's burning on all sides, or if I've got to offset my holder because it's too close to a wall, it involves breaking out of the Wizard. Then, in PowerSHAPE, I can go and individually pick surfaces, combine them, extend them, do what I need to do. I can then bring it back into the Wizard, and again get my location setup sheets automatically."

Staying Competitive

The global economy emphasizes speed-to-market. "A guy who comes out with a new product doesn't have that much of an edge over competitors because molds are getting built in a lot shorter time," says Janisse. A twenty-two-week leadtime is now a luxury, with eight to fourteen or fifteen weeks the norm. Janisse adds, "They want to make a trade show, and release the tooling just in time." Despite the pressures of international commerce and shrinking deadlines, Cavalier Tool & Manufacturing uses a careful blend of manufacturing and software technology to stay competitive and serve its customers well.

Related Content

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreHow to Clean and Maintain Molds With Intricate Conformal Cooling Channels

A water-based, eco-friendly plastic mold cleaning system helps Rankine-Hinman Manufacturing restore flow rates and avoid big-ticket failures on complex and costly molds.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More