Collaboration Makes the Impossible Possible

For Industrial Molds Group, successfully completing a complex 2×2, two-shot family mold demanded a level of collaboration similar to that required by a symphony orchestra. A leading manufacturer of power tools was under severe pressure to begin production for a new product that had to be on store shelves by Memorial Day or the customer (a major retailer) would cancel orders for the entire year.

For Industrial Molds Group, successfully completing a complex 2×2, two-shot family mold demanded a level of collaboration similar to that required by a symphony orchestra.

A leading manufacturer of power tools was under severe pressure to begin production for a new product that had to be on store shelves by Memorial Day or the customer (a major retailer) would cancel orders for the entire year. The OEM was caught off guard by this notice and was especially concerned because it was received just before the 2013 Christmas holiday season.

The OEM selected Industrial (winning the 2012 Leadtime Leader Award was said to be key to the decision), wrapped up negotiations on January 16 and placed the tooling order the next day. The clock was ticking. Industrial had 71 days to complete the initial tool build and ship it to the molder.

Not only was the mold complex, but the sheer number of companies and individuals involved in the project made collaboration complex, as well. The OEM had contracted the part design to a company in Minnesota; the injection molding to a company in northern Mexico; and, to save time on mold design, Industrial Molds enlisted mold/tool design service provider The Design Phactory. A total of five players were involved in the mold design phase alone.

Then the OEM made part design modifications (including a texture change requiring part draft concessions), and The Design Phactory requested part geometry changes to improve moldability, all of which were implemented and documented within hours.

Industrial co-owners Tim and Eric Peterson chose 25-year veteran Kerry Smith to oversee the entire project, primarily because he was instrumental in developing the majority of the company’s strategic vendor relationships. “Jobs like this can’t even be considered without the right people in place, both internally and externally,” Smith says. “It takes years to develop the talents and relationships necessary to meet these kinds of demands.”

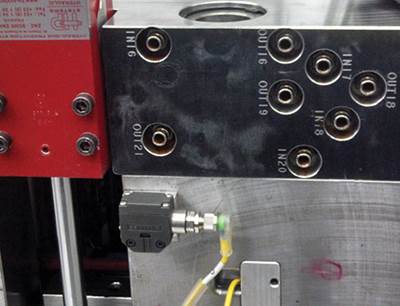

Smith began organizing and motivating key decision-makers even before the purchase order was released. He chose veteran Dean Franks as lead toolmaker and would rely heavily on EDM/Automation Manager Dennis Nord. He chose Incoe as the hot runner supplier because of its proven product quality and delivery. Mold-Tech committed to shaving three days from the texturing process, and this would play a major role in the project’s success.

There were challenges, but thanks to the cooperative efforts of those involved in the project, they were quickly resolved. For example, two weeks prior to the mold’s scheduled completion, the injection molder made a resin change. Fortunately, the new resin with UV stabilizers had a shrink rate very similar to that of the original resin, avoiding a potential catastrophe.

On March 29, the mold was placed on a truck for delivery to the Mexican molding facility. Mold sampling took place the following day with support from Industrial and Jesus Olivas, an Incoe technical specialist fluent in Spanish. The OEM’s engineering manager arrived a few days later for part inspection and a second round of sampling that resulted in quality first-shots—impressive considering the project’s compressed time frame.

As of this writing, the mold is back at Industrial for texturing and modifications to the steel safe areas. “We are grateful to have employees and partners capable of turning this challenge into a reality,” Industrial’s Tim Peterson says. With a smile he adds, “We’re ready for the next one.”

Related Content

Making Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreSteps for Determining Better Mold Prices

Improving your mold pricing requires a deeper understanding of your business.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More