Coatings and Finishes for Electrical and Electronics Molding

Electrical and electronic components take many forms and functions and require special attention when considering surface treatment options.

Today there’s hardly a situation in life that doesn’t involve the use of electrical and electronic com-ponents. Especially with the advancement of computers and entertainment products, both portable and otherwise, U.S. moldmakers and processors often find themselves manufacturing the tools and parts that function in one or both of these ways.

This article will discuss some of the advantages of using the finishes and coatings that help speed production and increase the quality of plastic electric and electronic components.

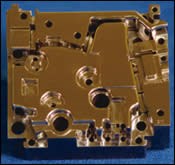

Electrical Components

First let’s address electrical components molding, which, for purposes of this article, encompasses such products as motor starters, circuit breakers, switch covers and light bulb sockets. Many more products fall into this category and most are molded using glass-filled materials. The molds used require protection from the abrasiveness of the materials; otherwise you risk the rapid deterioration of the steel over the course of the molding lifecycle.

Applying a high diamond polish coupled typically with chrome plating is recommended for effective protection from abrasion. With proper preventive maintenance, and by using an educated eye to know when the chrome requires refurbishment, the tooling can often be run for millions of cycles year after year.

Automotive

Approaching this subject by industry, the automotive sector encompasses both electrical components (coils, headlights and taillight connectors, ignition parts and spark plug connectors, for instance) and electronic components (such as stereos, dashboard assemblies, lighting systems, seat positioning motors and more). Anything found under the hood or inside the dashboard usually requires only good release during its manufacture. So a paper or draw finish is recommended and will provide very effective production outcomes.

On the other hand, more visible automotive components usually tend to be decorative in appearance, so an A-1 or A-2 diamond finish is recommended. In addition, because these tools often have multiple cavities, it is suggested to also apply nickel-boron-nitride for added release benefits. It improves material flow, which can be a concern with larger molds, and also provides flawless operations with the added benefit of corrosion protection.

Another aspect to consider with automotive components—and this also applies to appliances and personal electronics—is assembly. In some instances shops are working with very close tolerances and molded components must fit tightly together. For ease of assembly, it is often asked that selective plating be performed to accommodate size and fit, which usually requires the evenly applied application of more than the typical flash of .0001-.0002 of electroless nickel. This heavier deposit helps adjust the size of the plastic part without compromising the integrity of the mold and requires no additional machining because of the uniform nature of electroless nickel application.

Tooling

When dealing with multiple insert molds for electronics, almost everything that has an electrical connector in it is manufactured with extremely tight dimensional clearances. Normally, when plating these tools, it is asked that millionths in tolerances are held. Typically, the finish required is a very fine EDM or draw polish, using either nickel boron nitride or nickel-PTFE for the release characteristics.

Tooling for control panels for washers and dryers, dishwashers and stoves, microwaves and more—items used every day—require different surface treatments for various parts of the molds. For example, on the core side just a draw finish for release is applied. Again, this is because appearance is not a factor. But on the cavity side there is either a need to produce texture on the molded part or a diamond polish for aesthetics—or even a combination of both.

Also, many home appliances have touch panel controls. For these molds, graphic printed acrylic or polycarbonate sheets .010-.015 thick are over or under molded. With this type of molding the inks on the sheets are abrasive and corrosive when introduced to the heat during molding and can form a residue that can attack the mold. Electroless nickel will provide protection; however, if lubricity also is needed, nickel-PTFE or nickel boron nitride is recommended. An added plus of these coatings is that they also will help prolong the life of the tool.

Other widely used home products such as smoke and carbon monoxide detectors are manufactured using flame-retardant materials. A protective coating of nickel-PTFE for corrosion protection offers much the same protection that electroless nickel provides for products molded from PVC.

Personal Electronics: Treatments Are as Varied as the Products

Personal electronics come in so many shapes and forms it would be difficult to name them all. From televisions to cell phones to iPods and DVD players, not to mention the accessories that go with them, the market is booming with products to suit every lifestyle and every taste.

These molds need surface treatment and the treatments can be as varied as the products themselves. For example, when multiple finishes like polishing and texturing are required, polishing the tool before texturing it is often done, then plating of the polished, textured cavities with either nickel-boron-nitride or nickel-PTFE to aid release and provide corrosion protection.

Other times a combination of a texture and polish on the same cavities is used. In these cases, the mold must be masked to separate the polished areas from those that must be low-pressure vapor cleaned and prepared. Then the texture undergoes what is called a gloss adjustment.

Gloss adjustments are a surface treatment necessitated by the fact that components for one product (i.e., a refrigerator) are manufactured in different parts of the world today and when assembled must be compatible. So each component must be tested using a gloss meter to ensure a specific finish match. The required finish is established first based on the results shown by the gloss meter and then protected with the appropriate coating. The result is extended molding time between preventive maintenance checks and added protection of the desired gloss levels.

No Room for Error

Customers molding such products as automotive door and window switches, pin plug connectors, assemblies or housings and other such high end electrical products have no room for error due to the nature of the products and the liability involved.

Insert molds are a large part of the electrical and electronics industry. These molds are built for extremely high production and must run flawlessly. Production is automated and often metal inserts are involved, introducing additional risk for surface wear, so abrasion is a big concern. For these customers, the use of hard chrome, electroless nickel or nickel boron nitride is recommended. Depending upon the exact application and customer requirements, each of these coatings provides protection from corrosion and abrasion and also offers better release.

In combination with insert molding, thin-wall molding and multiple finishes must be dealt with. As stated previously, a protective coating will aid in protecting the integrity of the tool from a wear standpoint and can serve as a wear indicator to alert for the need for preventive maintenance—saving time and money over the long haul.

Nothing is guaranteed to last forever, but the key to prolonging the life of a mold is the use of a protective coating, whether molding parts for electrical or electronics parts. The aforementioned are recommended solutions, but it is recommended that you consult with a preferred vendor early in product development to ensure the best surface treatment is chosen for any particular job.

Related Content

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreRead Next

Reducing or Maintaining Cycle Times with Mold Coating

No matter the size of a tool, taking into consideration your GPM within your tooling’s cooling systems and using electroless nickel coating is an effective way to improve or maintain desired cycle times.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More