CNC Machine Simulation and Optimization Software

VERICUT 7.

CGTech is now shipping the next major version of VERICUT CNC machine simulation and optimization software. VERICUT 7.1 features significant enhancements to reduce the time required for manufacturing engineers to easily develop, analyze, inspect and document the CNC programming and machining process. Along with proactively adding new features, CGTech developers and engineers focused on addressing hundreds of customer-driven enhancements.

“VERICUT 7.1 builds on CGTech's highly successful VERICUT 7.0 release, and subsequent point releases, that contained over 700 customer requests delivered throughout 2010,” said Product Marketing Manager Bill Hasenjaeger. “Version 7.1 contains over 400 customer requests and further improvements to VERICUT's user interaction, simulation capabilities & analysis, cutting tool creation, and CAD/CAM integration.”

Product/Function Overview:

VERICUT is CNC machine simulation, verification and optimization software that enables users to eliminate the process of manually proving-out NC programs. It reduces scrap loss and rework. The program also optimizes NC programs in order to both save time and produce higher quality surface finish. VERICUT simulates all types of CNC machine tools, including those from leading manufacturers such as Mazak, Makino, Matsuura, Hermle, DMG, DIXI, Mori Seiki and Chiron. VERICUT runs standalone, but can also be integrated with leading CAM systems such as Catia V5, NX, Creo (Pro/E), MasterCAM, EdgeCAM and GibbsCAM.

The Project Tree, first introduced in VERICUT 6.0, continues to be refined to make VERICUT sessions simple to set up. A shortcut Toolbar has been added to enable quick transitions to a particular Project Tree branch. Holding the cursor over the icons will display what branch the icon goes to. Model file names are shown in parentheses for all models that have model files associated with them. Double clicking on NC Programs, or NC Subroutines, displays the appropriate file selection window. Also, NC Programs and NC Subroutine files can be added by simply right-clicking in the Project Tree. To quickly correct any possible user errors, a general purpose Undo/Redo button is available at the top of the Project Tree.

Cutting conditions are shown in the status display and available when stepping through the program using NC Program Review. The feature shows detailed information about the cutter’s engagement with material, including: axial depth, radial width, volume removal rate, chip thickness, maximum surface speed and contact area.

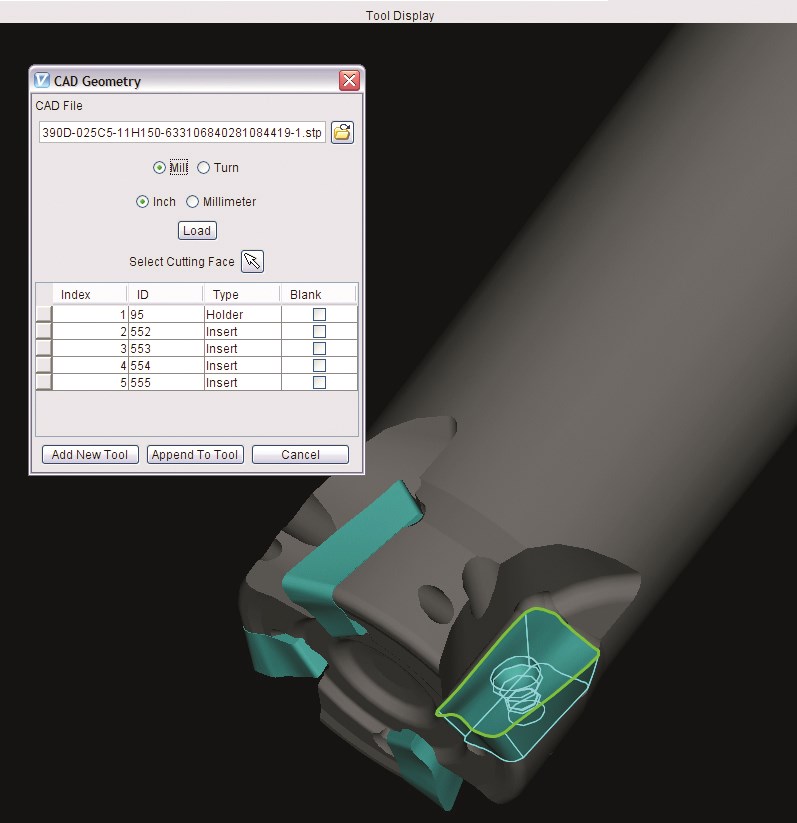

To further simplify creating a VERICUT tool library, CAD solid models of inserts and holders can be imported into VERICUT. The new feature added to the Tool Manager displays the CAD Geometry window that allows easy identification of which parts of the CAD model file corresponds with holders, cutters, or inserts. CATIA v5 and STEP models are supported.

It is now possible to create and display coordinate systems in the Tool Manager. These coordinate systems can then be used to align tool components.

A new feature, Assembly, in the Open model file selection window enables the user to extract all individual components of a CAD assembly file and store them in their own model definitions. If Assembly is toggled “on” (checked) a separate model will be created for each component in the CAD model. When toggled “off” (unchecked) all components are used to create a single model. This feature supports STEP, CATIA v5, and NX model types.

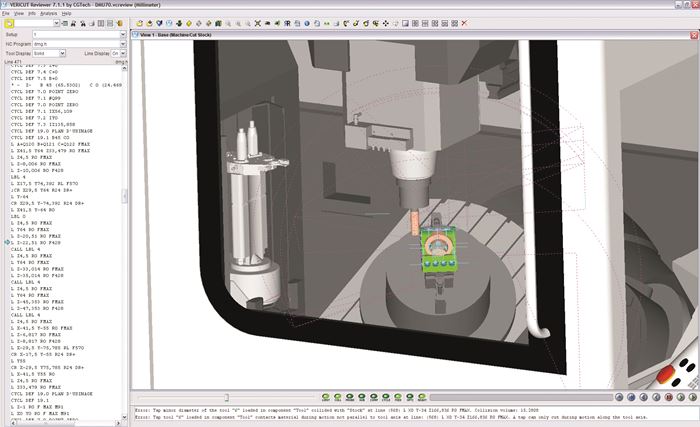

The VERICUT Reviewer incorporates all the functionality of NC Review mode in a stand-alone viewer that does not use a license. The Reviewer can play forward and backward while removing and replacing material. Error messages and NC program text is highlighted when a collision on the stock or fixture is selected. A tool path line display is optional. The user can rotate, pan and zoom just like normal VERICUT, and the cut stock can be measured using all the standard X-caliper tools. The “Reviewer” file can be saved at any point in a VERICUT session.

With the new VERICUT report enhancements, users can preview and customize report templates to include features such as pictures in tables, links to files, and links to websites. These reports have become increasingly valuable for VERICUT users to share CNC machining process information throughout their organization and supply chain.

A new feature has been added for VERICUT collision checking: it is now possible to stop the simulation at an “exact” collision point between the machine components. The new feature is turned on/off using the new Stop At Collision check box on the Start/Stop panel. The new logic is applied only to the Machine Simulation collision checking, and only to machine components other than the stock component. It is not applied to the holder/stock and tool/fixture collision checks. While simulating a NC block with the Stop At Collision box checked, VERICUT will stop in mid-motion at each collision point. Clicking the Step button continues simulation to the next collision point (or to the end of the motion if no other collisions exist).

VERICUT now supports material removal for gear hobbing and synchronizes the tool spindle with part spindle.

Additional enhancements include: the Pro/E interface has been enhanced to improve creation of parametric, sketch, and solid tools. Helical milling material removal is enhanced by creating a “true helix” motion type. Material removal for general broaching operations is supported. Simulation of back spot-facing tools is now supported. Diameter value is added to hole measurement information in X-Caliper. VERICUT now supports a full range of six-axis robots to simulate machining, waterjet trimming, fiber-placement, drilling and fastener insertion. A general linkage component is added to allow the connection of two driven components with a slaved linkage. The ability to output a NC program, of a different format than the input program, is added to base VERICUT functionality. The method for re-formatting the program is user-configurable. All popular controls continue to be enhanced with new advanced features: Siemens 840D, Fanuc 30’s, Heidenhain, Okuma OSP, Mazak Matrix.

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More