True Die’s investment in this ROMI/Siemens machine tool package has helped the shop reduce operating costs, improve profitability and establish a more open platform for employee and business growth.

Photo Credit: True Die Inc.

Tim Rietsma and his brother Mike started True Die, Inc. (Zeeland, Michigan) in 2000, wanting to continue their profession’s proud heritage of skilled toolmaking. But with the adoption of evolving machine tool technology, new ways of doing things have come, and soon the brothers faced an unexpected challenge to both their business and their ideals.

The toolmaking profession had changed. Qualified toolmakers were becoming scarce. While the trade had always been based on developing skilled and well-rounded toolmakers, the tech schools were beginning to turn out candidates for jobs in basic machine operation.

It wasn’t long before Mike Rietsma remarked to his brother Tim, “You know, you don’t see blacksmiths anymore either unless you go to a museum.”

Looking back, Tim Rietsma now observes, “When we started our company, I had 15 years of experience building molds and my brother had 20 years’ experience building stamping dies. The toolmaker that we had in the 1990s, I don’t think we’ll ever see that type of person again.”

With Evolution Comes Challenges

Contour Tool & Engineering, the company’s original name, was recently changed to True Die with new ownership, new round product tooling capabilities, and a renewed commitment to the toolmaking trade. As Contour Tool, the company has been a one-stop resource for OEMs needing an integrated knowledge and approach to building molds for injection-molded plastic parts. As True Die, Inc., leadership says the company’s heritage can now be more fully leveraged.

“As we design and machine a tool, we’re thinking about what goes into the finished part,” Tim Rietsma explains. “We see a problem at any step and we can solve it. Once that’s done, the rest is the machining. I’ve had job placement services come to me offering their services. I tell them I need a moldmaker or a die builder and they come back with someone who went to tech school and knows how to run a basic machine to cut a part. Then they say, ‘Well, that’s what you do here, right? Cut parts?’”

For True Die’s leadership team, two decision paths have emerged: Invest in newer basic machines that give a machine operator the ability to cut a part or invest in more capable machine/control packages that enable employees to build their skills and careers in the company.

Machine Decision Time

In 2014, the company bought its first ROMI machine, driven by their first Siemens CNC. The ROMI D1000AP vertical machining center featured the Siemens Sinumerik 828D control and drives package.

“We initially wanted higher speed and accuracy,” Tim Rietsma recalls. “With the molds, you cut both halves of the tool, and then both halves need to fit tight to each other within one-thousandth of an inch. If your machine can’t do this, you must spend a lot of time with a hand grinder on a bench.”

Doing away with bench grinding proved to be one of the immediate paybacks of the ROMI-Siemens investment. Any grinding-related variances in precision and surface quality were soon avoided and the increased capacity for throughput boosted the business’s profitability.

“Three years ago, most of our surfacing work was done at a feed rate of around 50 - 60 inches per minute,” says Rietsma. “With the Siemens and the ROMI combination, some of our feed rates have already approached 200 inches per minute; and what comes out of the machine is a part cut in much less time, and that offers repeated high quality to the customer.”

The new machine/control package has yielded other important returns for the company that continues to make the investment look all the better with each passing day.

We can get the surface finish that the mold requires and the maximum speed of the machine all at the same time.”

One-Pass Drilling

The ROMI D1000AP vertical machining center features integrated cooling during high-speed drilling. The coolant flows through the drill bit to flush the metal chips out and away from the flutes. As a result, carbide drill bits last much longer and drilling cycles have been reduced from five minutes to thirty seconds.

Now the shop can drill a hole in one pass, rather than repeating up-and-down

The ROMI D1000AP channels coolant through a high-speed carbide drill bit to flush out chips. One-pass drilling has given True Die, Inc. the flexibility to manage both higher margins and more competitive pricing.

passes to clear metal chips from the hole and bit. “So the price for a tool may be quoted at $25.00 for each of five holes,” Tim Rietsma explains. “Whatever the going rate, we can produce five of those holes in the time it used to take to produce one.”

This feature alone gives True Die, Inc. the flexibility to increase the company’s margins or to strategically price jobs to win new business, and sometimes both.

Faster-to-the-Finish

At every turn, the mold and die professionals at True Die have discovered something remarkable about the Sinumerik 828D CNC that drives their new ROMI machining center.

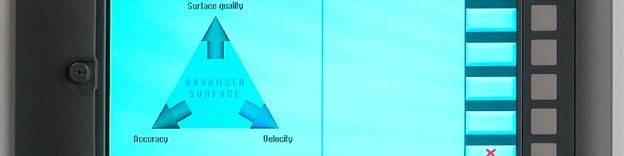

An important discovery was the ability to program the machine to minimize its time to cut a part. A feature called “Advance Surface” enables the shop to optimize mold-cutting velocity, accuracy and surface quality for the most efficient machining motion. So, for example, machine speed (velocity) can be reduced when the tool path requires the precise cutting of sharp corners (accuracy) and accelerated when machining through rough cuts to produce a part to the exact finish requirements (surface quality).

“It’s a feature that is over the top of any control I’ve ever seen,” Rietsma says. “With a couple of short clicks on the control, I can tell the machine that a particular block is not so fussy on tolerance. So I can, in effect, say, ‘open the tolerance up,’ which will increase the machine’s speed through that sequence. So we can get the surface finish that the mold requires and the maximum speed of the machine all at the same time.”

Beyond Easy-to-Use

Just about every brand of CNC on the market claims to be easy-to-use, but seeing is believing, Tim Rietsma says. “Siemens has outdone all their competitors. The CNC has full graphical support. You see what you’re doing while you’re putting in a program. With a lot of the other controls, you’re looking at the book trying to figure out what things mean.”

That said, investing in an easier-to-use Siemens control that drives an advanced ROMI machine was not the end-game for True Die. Instead, the more important goals were the enablement of the shop’s people, the betterment of the business and contributing to a toolmaking profession built on knowledge and skill development.

Among the advantages of the Siemens Sinumerik 828D control is the ability to produce a high quality part in the least amount of time. Surface quality, velocity and accuracy can be synergistically programmed to optimize machining motion using the “Advance Surface” feature.

Beyond “conversational,” the Siemens-ROMI investment enables the shop’s employees to build their knowledge and skills. “We’re still learning on the machine, learning every week,” says Tim Rietsma. “When the machine hit the floor, we needed to make parts. We didn’t have time to learn the CNC. And then, as the weeks go on, we learn a little more. The sky’s the limit with the Sinumerik 828D.”

Other proven returns on the machine/control investment have been the faster production of consistent quality molds; leveraging their newfound flexibility to produce different parts for different types of customers on the same machine; the ability to name and call up any of the tools in the tool holder; reducing mold rib cutting from a 20-hour off-line EDM process to a 1.5-hour milling process at the machine; eliminating hours of “homing” restart time in the mornings due to a Siemens absolute encoder that holds the exact previous setting, and being able to download earlier Haas and Fanuc files into the Siemens control with no losses and greater machining flexibility to gain.

The more important goals were the enablement of the shop’s people, the betterment of the business and contributing to a toolmaking profession built on knowledge and skill development.

Looking Ahead

True Die Owner President Brian Brown is incredibly proud of the company’s position and outlook on toolmaker education. A journeyman toolmaker himself, he is passionate about protecting and growing the trade by adopting more enabling technology and more robust education.

“Our business has a state-certified apprenticeship program,” Brown points out. “And our business is uplifted by companies like Siemens and ROMI, who understand the challenges of our industry. To further enhance our market/product offering, we just purchased our second ROMI to machine round tools for the deep draw industry... a C420 lathe with a Sinumerik 828D control that will be used strictly for hard turning.

This approach will minimize the need to ID/OD grind round tools after heat treating. Hard turning can hold comparable surface finishes and tolerances to grinding, but it is a much more efficient process.”

The toolmaker’s trade may have changed, but for True Die, Inc., the way forward includes investing in more open-ended technology that will build knowledge and skills, encourage inventive thinking, and reward career-minded workers who bring new ideas to the shopfloor.

Related Content

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More