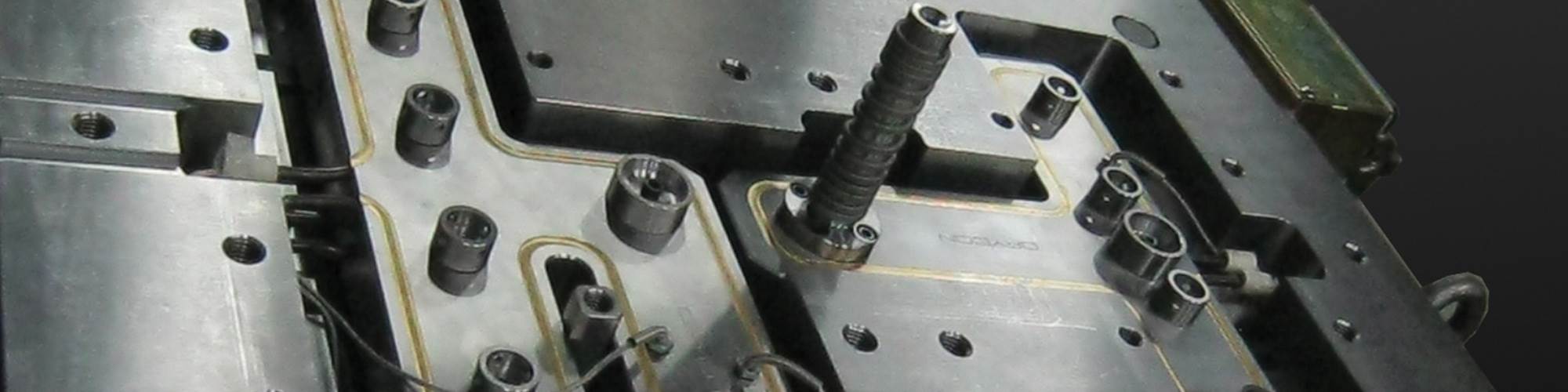

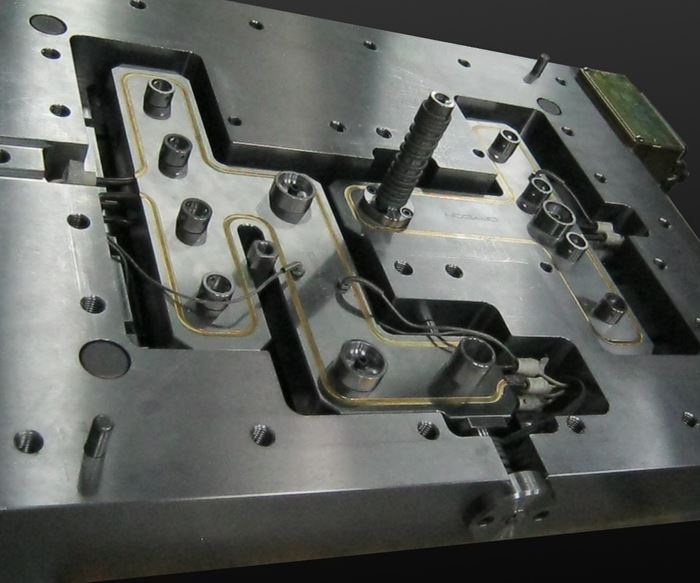

A hot runner is a very useful system in a mold. It helps accelerate the production of better-quality parts and enables gate placement in locations that are not possible with conventional runners. The caveat is that hot runner manifolds need more attention and a little extra skill to run and maintain than their conventional counterparts. However, that is true with just about all technology that delivers worthwhile benefits. When we like the pros, we learn to deal with the cons.

Many things can go terribly and expensively wrong with hot-runner systems, but the worst and most common problem is leaks. Plastic, water and hydraulic-fluid leaks can wreak havoc on a hot runner system. For example, a leaky connection in a water line can cause damage in the heaters or prevent heated components from operating at the proper temperature. A hydraulic-fluid leak from a valve-gate cylinder, actuator or fitting can short-out heaters, and on rare occasions, may even cause a mold to catch fire when the fluid leaks into the manifold area. Basically, the heat turns oil into vapor, and as soon as the first heater shorts-out and sparks, it ignites shooting flames that can reach the ceiling.

A hot runner maintenance program is essential for avoiding these problems and ensuring optimal hot runner mold performance. The most effective way to prevent manifold leaks and to keep systems running is a training program committed to sharing knowledge and experience.

Leak prevention must be part of the plan with hot runner training that includes the basics of hot runners, purchasing the best-suited type, processing and preventive maintenance.

Leak prevention must be part of the plan with hot runner training that includes the basics of hot runners, purchasing, processing and preventive maintenance.

The Basics

Toolroom maintenance personnel are involved in so many complex technical systems, from presses and tooling to robots and plastics, that they don’t have the time to master every area of the molding environment. Plus, they work with tight time constraints, so many take shortcuts and treat symptoms instead of determining the root cause of an issue.

Taking the time to became familiar with the basics of electrical theory goes a long way in solving problems. For example, it helps if the technician can easily determine how many watts a heater is producing, the correct wattage and the life expectancy of a heater. Learning how heaters are constructed, how thermocouples work and understanding thermodynamics and heat propagation also can be helpful.

This is all essential to preventing leaks because an electrical malfunction in the manifold system can cause overheating and overexpansion that can distort mold plates, which then can cause seals to lose compression. On the other hand, when part of the system is not hot enough, it can cause a plastic leak as the press tries to pump full shots while the runners are blocked. Faulty controllers also can cause these problems, so having controllers on a regular calibration schedule and keeping a close eye on the readings while running is also important.

Purchasing

A properly designed and built hot-runner system will improve performance and lengthen system life, so it is important to invest in the appropriate system for each mold. Mold buyers may specify the wrong system for a variety of reasons. For example, they may rely only on price considerations. Choosing a lower tooling cost can result in the most expensive purchase imaginable when downtime, repair costs and the inability to deliver the product come into play. On the other hand, choosing the most expensive system under the “you get what you pay for” theory can turn out to be disappointing too. These systems can have problems that often result in unexpected costs, lost production time and missed deliveries. Using the price tag as an indication of suitability is not the best yardstick.

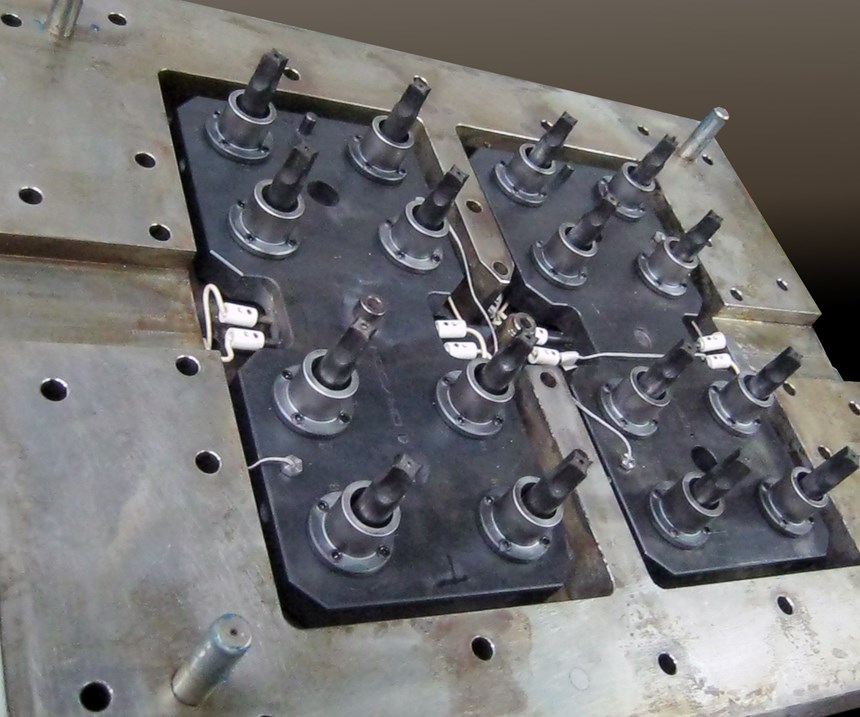

One needs to consider system construction and then decide based on the design, reliability history and the application of basic technology. The technology involved is a little complex, but nothing in it is rocket science. Once it is explained, most tooling professionals will understand what makes things work and the difference between the various system options.

Processing

Hot-runner leaks can be “headed off at the pass” during processing by paying attention to seemingly minor changes in the molded parts or press behavior. If a press and the mold (including the manifold system) are functioning properly, they will repeat cycle after cycle without any changes to the original molding parameters. Short shots suddenly appearing in the middle of a run or new setups requiring more material volume than previous runs indicate that the plastic is moving to an unintended location. Often, operators will notice these changes and then make setting adjustments to continue producing acceptable parts. Instead, they should stop operation to lessen any damage and ease the process of returning the mold to proper operation. If the mold must be removed from the press for repairs, early leak detection will make the difference between one or two hours or days of interruption.

A few other simple actions to take to help extend the life of the hot-runner system include starting up the heaters with the warm-up or soft-start cycle, especially on high humidity days; checking for water or oil leaks; running the system at the proper temperatures and lowering the setpoints of the hot runner when the press is idle.

To extend the life of the hot runner system start up heaters with the warm-up or soft-start cycle, check for water or oil leaks, run the system at the proper temperatures and lower the setpoints of the hot runner when the press is idle.

Maintenance

Maintaining hot runner systems can be simplified by adhering to the following rules:

- Check for any connector damage when a mold comes off a production run. This includes connector pins that may be bent or pushed into the sockets, cracked housings and deformed or broken latches.

- Check the resistance of each zone and compare to readings that are recorded prior to the last run. Resistance changes, especially when the reading is increasing, indicate impending heater failure.

- Check all thermocouples with an ohm meter and compare readings to those taken prior to the run. A difference in readings within a few ohms is acceptable, but large variations indicate a possible loose connection or a damaged thermocouple. Please note that wire splicing in thermocouples should be done with silver soldering only, as thermocouples emit a signal of only a few millivolts, and a crimped splice will likely get oxidized at the point of contact, lose continuity or provide a false reading.

Performing these maintenance checks regularly at the end of each run will greatly reduce the risk of leaks and ease mold setup for the next run.

About the Contributor

Sal Benenati

Sal Benenati is the COO of Orycon Hot Runner Systems.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More