Automotive & Medical

Auto Industry Outlook: Continued Growth; Medical Industry Gains Will Stay Robust

Auto Industry Outlook: Continued Growth

One of the true bright spots in the economy over the past 24 months has been the automotive industry. In 2011, the number of motor vehicles assembled in the U.S. expanded by 12% when compared with the previous year, and in 2012 that rate of growth has accelerated to over 20%. Our forecast for 2013 calls for another solid increase of 6 to 8%, and this will bring the industry back very close to pre-recession levels in terms of the total number of vehicles assembled.

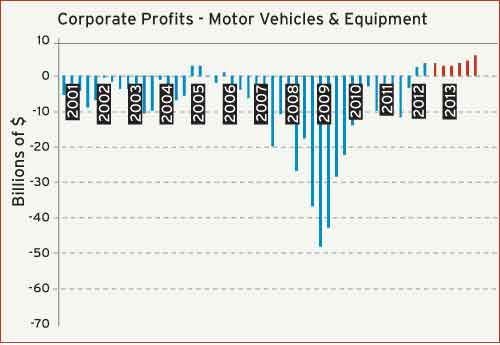

For moldmakers, plastics processors and other suppliers to the auto industry, a trend that is even more important than rising market demand for new autos is the trend of rising profitability for automakers. As the chart illustrates, profits in the auto sector have been hard to come by in recent years, but this situation may have turned the corner in 2012. After all of the trials and tribulations of bankruptcies and the government bailout, it now appears like the U.S. auto industry is once again making both cars and money. This should allow them to pay their suppliers and continue to invest in both products and ideas that will enhance their productivity and competitiveness.

There are a couple of trends in the auto market that will gain in importance in the coming years. First, natural gas will continue to gain popularity as a fuel for motor vehicles. As a result, toolmakers and processors will find opportunities in both new auto parts and also the expansion of the infrastructure needed to deliver natural gas at a retail level. Second, the price of steel and most other metals will continue to rise. This will push demand for car parts made of plastic because they are less expensive to make as well as lighter weight.

Medical Industry Gains Will Stay Robust

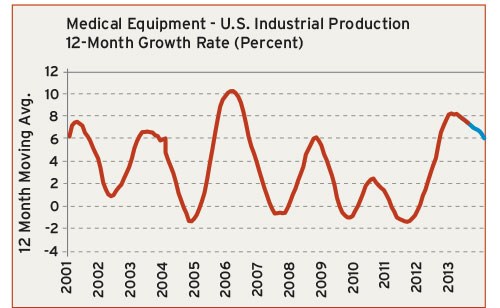

As 2012 comes to an end, the rate of growth in the U.S. output of medical supplies and equipment is approaching 10% on a year-over-year basis. This will push the total annual gain for this year to 7% to 8%. Our forecast for 2013 calls for another gain of 8%. This forecast is based on expectations that the Affordable Care Act (the ACA, a.k.a. Obamacare) will remain the law of the land, and its implementation will result in approximately 40 million new healthcare customers.

There is growing concern that the ACA as it is currently written is sustainable over the long-run, but for the foreseeable future I expect market demand for medical goods and services to expand vigorously. It is worth noting that much of the growth in demand for during the second half of 2012 may have been due to fears that Obama would lose the election and access to cheap healthcare via Medicare would be curtailed under a Romney/Ryan administration. So many seniors may have chosen to pull forward their covered procedures to 2012 as a precautionary measure. It would appear that this is now a moot issue, so demand will likely decelerate a bit.

One other potential factor on the horizon is that the tax on medical devices that was included originally in the ACA may have a chance to be repealed as part of the Grand Bargain that we hope to get in order to avoid going over the fiscal cliff. If Congress is serious about tax reform, and they should be, then one of the most prominent ideas is to eliminate tax deduction and loopholes for certain industries. But to be fair, this should also include the elimination of some of the taxes on other industries. It is way too early for anything other than speculation on this, but it is worthy of further investigation.

Related Content

Innovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

Read MoreLessons in Quality Assurance for Micro Projects

Quality control, quality assurance and measurement technology are central considerations for micro mold building and molding.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreInternational Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Read MoreRead Next

End Market Report: Aerospace/Defense & Packaging

Plastics Packaging Outlook: Moderate Growth in 2012, and Aerospace/Defense Spending Outlook.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More