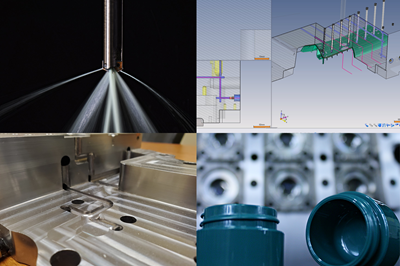

Photo Credit: Precision Laser Technology (top left), Kenmold (top right), Synergetic Eng & Manufacturing Services (bottom left) and Ellwood Specialty Steel Co. (bottom right).

Amerimold 2021 is less than two months away, so plan ahead for the mold manufacturing trade show taking place September 21-23 with a sneak peek of some more highlighted products and services from the show’s extensive list of exhibitors below. Click the title links for more information on each technology or check out the leading suppliers that will be exhibiting here.

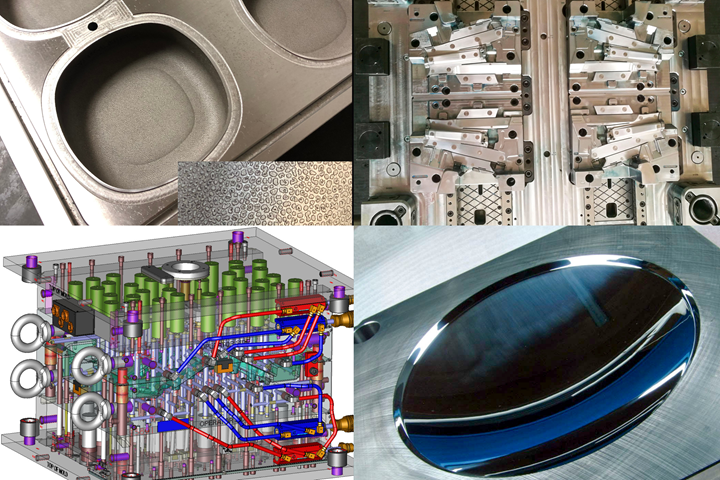

According to Precision Laser Technology (PLT), its utilization of laser texturing technology has surpassed traditional chemical methods for etching plastic injection molds. Five-axis mobility and digital interface improve the versatility for pattern designs, accuracy within mold placement and repeatability for multi-cavitation tools. Textures range from industry-standard VDI and matte finishes, to custom-designed 3D patterns.

GROB Systems presents its G150 horizontal five-axis machining center, part of the modular G-series system line the company says has continually set the bar for productivity and process safety.

GROB recommends the G150 for the precision engineering, medical technology, mold and die, mechanical engineering and aerospace industries, saying the G150 is the only horizontal five-axis machining center in its class.

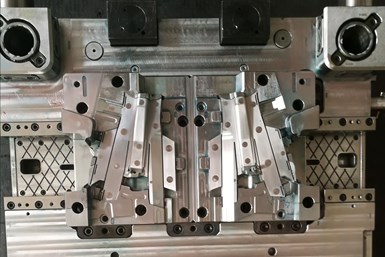

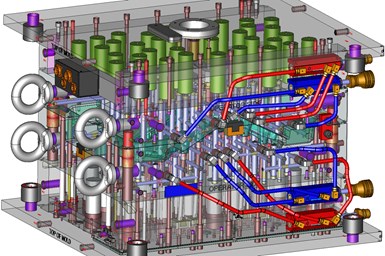

Kenmold is a full-service plastic injection mold manufacturer with more than 25 years servicing multiple industries. The company is experienced in manufacturing molds and molded components for the automotive, electronics, consumer goods, medical and other industries, as well as HDPE pipe fittings for the oil and gas industry.

Within those 25 years, Kenmold says it has obtained multiple certifications including ISO9001, ISO13485 and IATF16949 and was reportedly identified as a top 10 injection mold company in 2021. New product R&D, mold tooling, assembly and packaging are a few services Kenmold offer to customers.

PCP Aluminium promotes its ACLA5 and MAX5 Aluminum, the company’s AA5083 aluminum cast plate/block, which the company says continues to meet industry-best delivery lead times and quality performance. Inventory is available cut-to-size and delivered via PCP Aluminium’s distributors.

Moldex3D has announced the release of Moldex3D 2021, the latest version of its molding analysis software series. According to the company, the new generation of Moldex3D continues to refine simulation capabilities to provide better user experiences.

For example, retaining warpage prediction of injection molding, Moldex3D 2021 reportedly combines the material and stress characteristics of plastic phase changes in the packing stage, increasing the prediction accuracy. Further, mechanical property simulation is introduced to optimize the calculation accuracy of short fiber materials, enabling users to receive better results of warpage prediction of fiber-filled materials.

Ellwood Specialty Steel Co., a steel supplier with divisions serving the U.S., Mexico and Canada, introduces its superior P20-modified grade of mold steel to the mold-building industry and Amerimold 2021 attendees. Improved lens/texture quality (LTQ) alloy offers highly consistent surface finishing properties. Recognizing the increased demands for flawless diamond polish finishes on lens molds and complex geometric and delicate texture patterns, Ellwood says its metallurgists have engineered a steel that will perform to a user’s most stringent requirements.

PCS Company, alongside Filtroil, offers the injection molding and die casting industries oil filtration solutions engineered to achieve ISO Cleanliness Code targets and ensure quality, clean oil to improve the performance and life expectancy of all mold components.

PCS Company refers to solutions such as dedicated by-pass filtration on a hydraulic reservoir or a portable solution for light and heavy applications like Filtroil’s black gold oil filter cart (BGFC).

At Amerimold 2021, hot runner manufacturer Oerlikon HRSflow is featuring its S Series hot runner line in a reduced size. Enabling reduced pitch via its compact design, primary applications include the production of small technical parts using engineering plastics. Depending on the application, the S Series hot runner can be equipped with Sa series screwed-in nozzles or Tp and Sp nozzles, which are face-to-face products with different inner bore sizes.

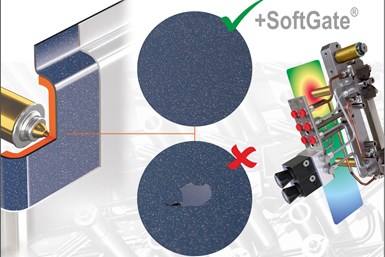

Several years ago, INCOE recognized the challenge of direct valve gating a part while overmolding film or fabric in mold decorating. For example, the “blast” of the plastic in the gate area can often damage the film or wrinkle the fabric. Using control technology, the company’s SoftGate Velocity VG pin enables these applications to be direct gated. This allows for the “gentle” flow of plastic into the cavity, eliminating blemishes that can occur with uncontrolled flow.

Syn Lube, a high-performance synthetic lubricating grease offered by Nanoplas Inc. is a full synthetic, food-grade grease designed for the most difficult industrial applications. With a temperature range of -100°F to 500°F, it can be used in almost any molding application, says the company. The synthetic formula includes anti-oxidants, extreme pressure and anti-wear additives that meet the most stringent requirements for industrial environments.

Mold-Masters will showcase its Accu-Valve premium cylinder valve gate components at Amerimold 2021, which feature continuous 360-degree pin guidance in close proximity to the gate for precise valve pin alignment that does not require direct reliance on cavity steel. This advanced design is said to significantly minimize wear of the gate and valve pin, factors that often lead to gate quality deterioration over time. By maintaining these critical, high-tolerance dimensions and concentricity, Accu-Valve avoids costly maintenance and downtime, enhances reliability and extends service life for millions of cycles.

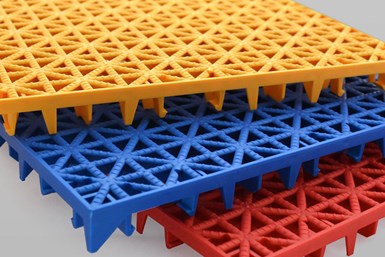

The new coinjection process, which Engel has developed in collaboration with Top Grade Molds, is said to enable higher recycled material content in the production of pails versus the conventional processes for sandwich injection molding. The process is said to use more than 30% of recycled material in the core during the production of five-gallon pails, for example.

Swiss Steel Group says it is continually developing specialty steels to combat highly corrosive injection molding environments, while also improving mold steel machinability and dimensional stability. The company offers Corroplast, its free-machining stainless steel mold base material as an example. The pre-hardened steel combines a special chemical composition with a special heat-treatment process, and is said to be an ideal material to resist corrosion associated with high-humidity environments and when corrosive resins are used in production.

Synergetic Eng & Manufacturing Services says its current focus in the development of XMD, an automated, knowledge-based mold design solution, is on ease of use. This has been achieved, the company notes, through the continuous leveraging of its intelligent automation technologies, with a conscious effort to afford all the advantages XMD offers to new users, and less experienced designers, such as eliminating extensive training requirements to be able to use the software.

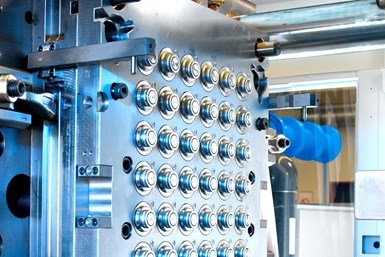

Superior Die Set’s Threadformer unscrewing devices are designed to provide a simple solution for complex unscrewing molds, alleviating the difficult task of unscrewing molds without compromising the part. According to the company, a compact, yet highly powerful hydraulic motor rotates the core holder in and out of the mold. To guarantee a precise thread start position, the core holder runs against a fixed stop, which is typically the mold base.

Paulson Training Programs Inc. is a dynamic technical training company that teaches the fundamentals and advanced topics of scientific injection molding, extrusion, thermoforming and blow molding for the plastics industry. This is done through the “Plastics Point of View,” via intensive, online-based and instructor-led seminars, which are geared toward a range of job functions including injection molding machine operators, extruder operators, molding technicians, production floor troubleshooting personnel, supervisors and managers.

In addition to features such as moldmaking assistant, the generation of parts lists and direct and easy ordering of quality mold units, Hasco has added the SET (Standard Engineering Tool) to its online portal. According to Hasco, the newly developed offline software program is geared specifically to the needs of mold designers, with the ability to adapt to an individual’s needs for increased efficiency.

Progressive Components introduces the C-Series UniLifter mold undercut release system, which is able to compensate for misaligned mold ejector plates.

The new C-Gib features a cylindrical surface that the C-Coupling travels along when ejecting a molded undercut. Said to be able to self-adjust in both the X- and Y-axis, smooth travel along the black-nitrided surfaces reportedly prevent stress and wear between core blades and mold inserts, while providing a surface against molding pressure versus the single point contact of dowel pins or tooling balls.

Asaclean’s new PLUS Grade, a high-performance purging concentrate, was designed to perform best in mold processors’ hardest applications, says the company, while offering the same performance and cleaning power of Asaclean’s Purging Compounds. The heat-activated concentrate, compatible with a user’s own production resins, is ideal for hot runners and low flow areas and dramatically cut down on changeover times and bad parts.