Photo Credit: Cheto Corporation SA (top left), Fast Heat Inc. (top right), The Plastek Group (bottom left) and Horn USA (bottom right).

Amerimold 2021 is only two months away! Plan ahead for the mold manufacturing trade show taking place September 21-23 with a sneak peek of some highlighted products and services from the show’s extensive list of exhibitors below. Click the title links for more information on each technology or check out the leading suppliers that will be exhibiting here.

The Plastek Group was originally founded by Joe Prischak in Erie, Pennsylvania in 1956 as a small injection mold building company. Today, the family-operated company is a globally recognized injection mold builder, molder, assembler and decorator. To remain competitive, Plastek says it invests heavily in automation and other labor-saving equipment for all its moldmaking and molding/assembly/decorating operations.

Amerimold 2021 exhibitor Fast Heat Inc. by Spark Industries will be demonstrating its Pulse hot runner temperature controller which protects heaters and thermocouples, prevents operator errors and enables users to specify production cycles. Pulse can be complemented with Fast Heat’s proprietary Mold and Cable Checker tools for diagnosing hot-half and cable issues.

The PG1000 optical cutting tool inspection system to be demonstrated at Amerimold 2021 by PG Inspection Tools ensures that the cutting tools used to manufacture molds or any other parts are within the manufacturer's specifications. The PG1000-200 and PG1000-400 models, specifically, are durable and easy-to-use systems that allow the user to take tool geometry measurements down to the micron level.

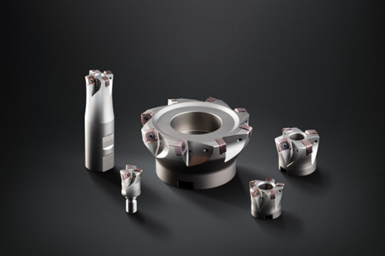

Horn USA Inc. will be presenting its new development for high-feed milling, including the next-generation DAH82 and DAH84 systems, at Amerimold 2021. According to the company, the precision-sintered insert has eight usable cutting edges, resulting in a low cost per edge and a high level of cost-effectiveness.

Entegris/Poco Materials, a manufacturer of EDM grades of graphite electrode materials and provider of EDM performance solutions, will be offering a virtual option to its well-known EDM technical training program beginning in August 2021.

The virtual training will be divided into modules which can be downloaded from the Entegris/Poco Materials website. The modules will include presentations, videos, Q&A sessions and quizzes to mark a user’s progress

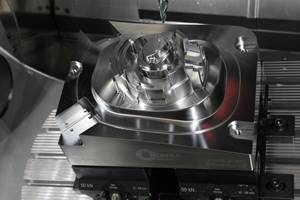

The multitask gundrilling machine from Cheto is said to be a type of deep-hole drilling machine that maximizes the performance of the drilling tool. Thus, says Cheto, it is possible for the machine to drill holes at great depths and with extreme precision in any type of materials. Cheto’s machines are all in one: They are applicable for drilling (deep-hole and conventional), milling, tapping and boring.

According to Wittman Battenfield Inc., its new compressed air resin dryers (CARD) offer molders an efficient solution to achieve optimal drying results as low as 0.35 lbs/h, even with small material throughput rates. Various functions such as the Sleep mode, the Rampen mode the Count Down mode and the Power mode support the production process and ensure adequate as well as gentle and energy-efficient drying.

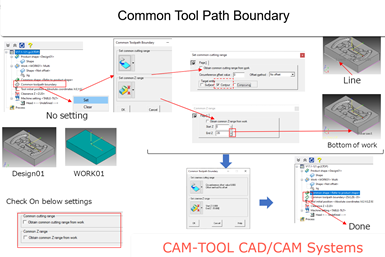

CAM-Tool by CGS North America will be releasing version 17 in North America this summer 2021, as well demonstrating the CAD/CAM software at Amerimold 2021 in September.

According to the company, one of the major improvements featured in Version 17 is the addition of a toolpath boundary in the Common Settings. The Common Settings will now allow users to set a shape, stock model, toolpath boundary and Z cutting range which can then be applied to all toolpaths.

Special Springs North America, a subsidiary of Special Springs s.r.l., announces the official launch of its improved, state-of-the-art, mechanical die spring line, US Series. The US Series by Special Springs has been updated from the company’s previous stripped die spring product line to better align with the demands of the North American market, and will be demonstrated at Amerimold 2021.

The Erowa Technology PowerChuck P is said to be the universal interface for quick and precise positioning of palletized workpieces or fixtures on a machine table. With the new PowerChuck Edge 20, the workpiece palletizing system has been updated with a new, innovative design and functions.

With its most recent 1.3.0 software upgrade, Heidenhain’s StateMonitor system now enables CNC manufacturers a modernized and more effective way to connect their control and PC systems. Including additional StateMonitor options, users involved in this Industry 4.0-connected machining initiative can view data and evaluate control processes remotely and in real time in a more simplified manner.

.jpg;maxWidth=300;quality=90)