All About the People

The right skillsets have been essential not only to this company’s core mold manufacturing business, but also its diversification into completely new sectors, such as industrial automation.

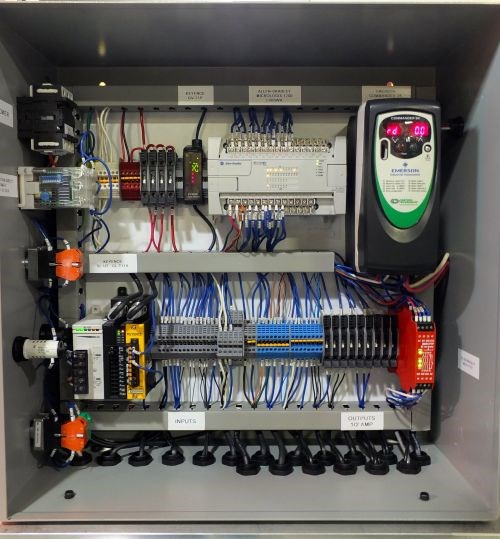

The assembly station in this video is a typical example of Ameritech Automation Systems' work.

To say that Ameritech Die and Mold relies heavily on automation would be an understatement. Here, automation isn’t just a means to improve manufacturing efficiency—it’s a whole segment of business in and of itself. Yet, the evolution of that business demonstrates that regardless of how far things have come, the people behind the technology remain as important as ever.

Ameritech has relied on robotics, pallet systems, standardized workholding and the like for some time now, both at its main location in Mooresville, North Carolina and at a second facility, Ameritech South, in Florida. Early last year, however, the latter operation found a new niche. Operating under the name “Ameritech Automation Systems,” the new division focuses on engineering and manufacturing solutions for pick-and-place, degating, assembly and other such operations at custom molders and other customers.

The division got its start when a custom molder located near the Florida facility ran into trouble with one of its automation solutions providers. One veteran employee thought he could do better. He’d just need a reliable, trustworthy machine shop, one with whom the company had a good relationship to execute his plans for a new assembly system. Enter Ameritech. However, both parties lacked the necessary experience with interfacing the pneumatics and hydraulics.

This shot depicts the wiring and enclosure for the system shown in the video above.

Fortuitously, Rusty Rotman, Steve’s cousin and manager of Ameritech South, knew just the guy. Joe Johnson, whom Rusty met at church, had the requisite experience, and he was nearing the end of a temporary job. Johnson was quite eager to come on board for that project, and today, he’s program manager at Ameritech Automation Systems. “Joe offered the capability to help develop that division for us at a higher level, with multiple customers,” Steve Rotman says.

These five workstations that assist workers in assembly of automotive components.

Ameritech South’s earlier diversification into aerospace industry work in 2009 is a similar story. Again, there were plenty of synergies—the company certainly had the expertise and technology to machine discrete parts, and it found plenty of mold work in that sector, too. However, Rotman credits the hiring of an aerospace industry veteran, Chuck Laymon, for providing the necessary experience to guide the company through the process of earning AS9100 certification.

These aren’t the only two individuals that make Ameritech South and Ameritech Automation “tick.” For instance, Johnson credits much of the latter division’s success to dedicated toolmaker Rich Smith. “Rich is quite literally the backbone of what we do here,” he says. “He has been able to take vague concept ideas presented from the customer and turn them into working equipment before I ever came on board and helped with creating complete designs. He really helped to drive realization that this is something Ameritech could do as a service for our customers.”

I didn’t speak to Smith, but I’d guess he would likely say similar things about other team members, who would likely credit other coworkers, and so forth. Indeed, singling out everyone’s contributions would be impossible. Suffice it to say that Ameritech views people as far and away its most important resource. If the above isn’t evidence enough of that, consider the fact that the company’s workforce development efforts have attracted at least as much attention as its automated, standardized approach to manufacturing. As a founding member of Apprenticeship 2000, the company has long focused its efforts on developing talent, and a large portion of the staff at its North Carolina headquarters facility is less than 40 years old. Rotman comments on the program in this Q&A from last year.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More