"Adding" to Your Tooling Options

Understand the benefits and applications of processes for making tooling through additive manufacturing.

Additive manufacturing (AM) has come far since first gaining traction in the 1990s. In recent years, the technology has seen an official name change from the old term “rapid prototyping,” the creation of an ASTM International committee on standards, and the announcement that the pilot institute for the new National Network for Manufacturing Innovation will focus on additive manufacturing. If you are watching AM but not yet working with it, you may be left behind.

According to ASTM F2792-12a, rapid tooling (RT) is defined as the use of additive manufacturing to make tools or tooling quickly. Rapid tooling went through a push in the ’90s when processes such as Direct AIM, 3D Keltool, QuickCast and others were created. Most of these processes faced material and process limitations, but a few survived. Recently, there has been a resurgence in attention to AM tooling thanks to both material and process improvements.

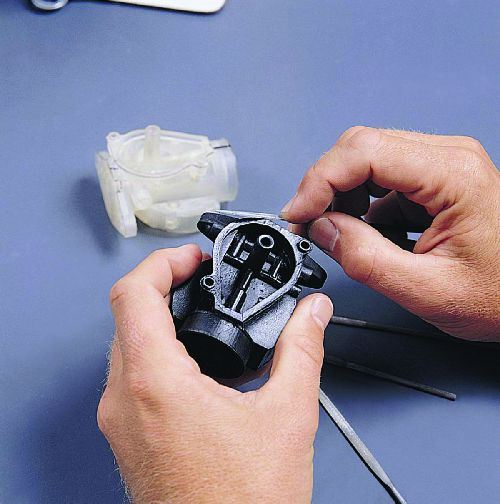

There are two broad categories of tooling from AM. One involves indirect approaches that use a master pattern to create a mold or die, such as a silicone rubber mold made from a master. The second category is a direct approach in which the AM machine builds the actual tool or tooling insert. Direct metal laser sintering (DMLS) from EOS, ProMetal from ExOne and LENS from Optomec or POM are examples of processes that can directly produce metal tooling.

Additive vs. Subtractive in Tooling

In contrast to these additive approaches, CNC machining, the conventional approach to toolmaking, is an established and well-understood technology that is currently the worldwide standard for producing prototype and production injection-mold tooling. Whether the machining is entirely milling or includes EDM, CNC machining is not subject to the material, size and accuracy limitations inherent to most unconventional toolmaking processes. Plus, the leanest mold suppliers are discovering that machining molds does not need to take months.

Here are some general differences between AM and CNC machining:

• Surface finish. AM is rough without secondary operations. A system with layers at 0.0005-0.001 inch might produce an Ra finish of 100-600. CNC can produce surfaces that are smoother.

• Feature detail. AM typically is better for part features in special situations where CNC cannot make the geometry. Examples include internal features and trapped geometries.

• Part size. 24 × 36 × 24 inches is typical for AM, though larger systems exist from such manufacturers as Materialise, Stratasys and Voxeljet.

• Geometry/complexity. AM handles geometric complexity easily. CNC’s geometric limitations include deep slots, deep holes and undercuts.

• Accuracy. AM offers tolerances of +/-0.005 to 0.020 inch. The comparable tolerance range for CNC is +/-0.0005 to 0.005 inch.

• Speed. AM is faster for small, complex parts, while CNC wins for large, less-complex parts.

• Labor is low for AM in terms of both the amount required and needed skill level. Setup time, operator attendance at the machine and the requisite skill level are higher for CNC.

Direct Tooling

Direct approaches to tooling using AM do not require a pattern, and numerous additive options exist for making metal or plastic components. These can reduce the number of steps in the toolmaking process, saving cost and time.

Some manufacturers have been using AM to produce metal inserts for injection mold tooling, including Linear Mold of Livonia, Michigan, which has been successfully producing injection mold components off of DMLS inserts for several years. (Editor’s note: See our article on Linear Mold at short.moldmakingtechnology.com/linmld.)

One of the most popular forms of direct tooling from the ’90s, Direct AIM, used stereolithography (SL) parts as molds. It was developed for small runs of injection molded parts off of a relatively cheap tool. Though this process had been in decline, a small rebirth has occurred in recent years thanks to tougher SL materials such as ceramic-filled Nanotool from DSM Somos.

3D printers also should not be overlooked. 3D printers from Objet, 3D Systems and Stratasys can be effective rapid tooling machines, especially when casting thermoset plastics and rubbers. Stratasys fused deposition modeling (FDM) prints have also been successfully used for thermo/vacuum-forming direct molds. The porous nature of tooling produced this way enables air to pass through, possibly preventing the need for hole-drilling. FDM tools are also being used for more demanding direct applications such as stamping and hydroforming tools.

Direct tooling isn’t necessarily limited to small components, either. ExOne and Voxeljet both have large systems that can produce direct tooling, including Voxeljet’s VX4000, which is capable of building tooling larger than 12 × 6 × 3 feet.

Indirect Tooling

Several pattern-based processes have been developed for creating a tool rapidly through AM, with varying costs, lead times and process capabilities. In general, any process—whether additive, subtractive or formative—can be used for indirect tooling. The accuracy of these processes depends, in large part, on the accuracy of the method used to create the pattern.

Few areas of manufacturing have been impacted as much by AM as investment casting. Early on in the development of AM, Helisys’s laminated object manufacturing (LOM) system used layered paper for casting patterns because of the low ash content. Companies now make casting patterns via QuickCast (a stereolithography build style), jetted wax and resin systems such as PolyJet and Multi-Jet Modeling (MJM), and with selective laser sintering (SLS) for polystyrene and FDM for ABS.

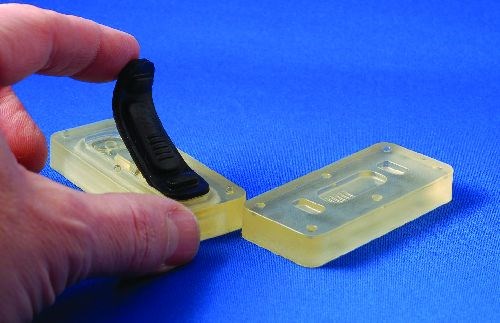

In the plastics field, many companies that need to produce a relatively small run of plastic parts employ silicone rubber tooling made from an AM pattern. This can include basic room temperature vulcanizing (RTV) molds poured onto an AM pattern or rotocasting (spincasting) of urethane. When higher quantities are needed than an RTV mold can accommodate with its average life of 25-50 units, epoxy tooling is an attractive option. Used for reaction injection molding (RIM) or standard injection molding, epoxy tooling can be a cost-effective method to produce bridge tooling.

Sacrificial (one-time) molds also can be useful in AM, and FDM technology has been used successfully for wash-out mandrels in the composites arena. Other pattern-based RT processes include cast kirksite tooling (epoxy tooling with filler), 3D Keltool, MetalCopy, PHAST, V-Process and rubber plaster molding (plaster casting).

High-Performance Tooling

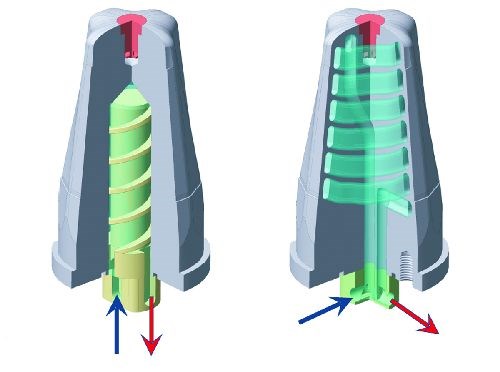

With high-performance tools, molding cycle time is more important than the time it takes to produce the actual tool, and creating conformal cooling channels within the tool using AM can help speed the molding cycle. These channels conform to the shape of the mold cavity and enable coolant to pass through, removing heat from the mold or die faster and more evenly than straight-line channels. Tests suggest that conformal cooling can reduce cycle time by 30 percent or more and improve part quality. The result can have a significant impact on part costs and production rates.

Another method of thermal management is the use of functionally graded materials. The idea is to use a hard, resistant material such as H13 tool steel for the surface of the mold and a highly conductive material such as a copper alloy for most of the remainder of the mold. Optomec and POM—both using LENS technology from Sandia Labs—have successfully used additive manufacturing to directly produce molds and dies with copper cores.

Ultrasonic Consolidation, commercialized by Solidica, is now being promoted for rapid tooling by Fabrisonic under the name ultrasonic additive manufacturing (UAM). The process can produce molds out of aluminum, copper and steel that can be used for die casting, investment casting and vacuum forming. UAM can produce complicated conformal cooling passages and also bond dissimilar metals, allowing for molds with multiple materials. Spray metal technologies, such as those from RSP Tooling and Ford Motor Co., also have demonstrated significant tool life improvements with functionally graded materials.

Jigs and Fixtures

AM has also been used for several other types of tooling, including jigs, fixtures, templates, drill guides and other devices. Where this tooling involves complex shapes or multi-axis hole patterns, AM can provide significant benefits. Shapes are digitally and accurately produced to match for registration. The number of copies of fixtures or jigs required on an assembly line often is quite low, but after producing the first iteration of a tool, successive versions can be produced quickly as needed. Other tooling suitable to be made this way includes conformal press tools, drilling and trimming guides, wire harness check gages and holding tools for quality control inspection.

Future Opportunities

Although many niche solutions exist, an advance is needed in the area low-volume production. For quantities between 100 and 500 units (depending on size and complexity), it can be difficult to determine the best AM or tooling-based process. One reason for this is that requirements change daily in the shop. An engineer may need to tweak a shape or geometric feature, or a customer may need 10 units one day and 100 the next, followed by 50 of a different design permutation. Because of their thermoplastic material outputs, FDM and SLS, coupled with post-processing innovations, will likely make an impact in this area. Also, metal AM companies like EOS and ExOne can improve machine tools and processes to deliver fast, accurate and smooth parts directly from the machine.

Design limits have not been removed by AM, but they have changed. The feasibility of conformal cooling is an example of this change. Now that the new constraints have been defined and awareness of the change is advancing, increasingly innovative thermal management solutions are likely to be developed.

An important consideration in assessing why AM hasn’t made a bigger impact to date on tool making is that real, value-added change takes a long time to implement. Even as effective rapid tooling methods evolve, a company that is already knowledgeable and efficient in its current methods will typically be reluctant to change. The most effective driver for change can be competition. When a few trailblazers prove the value of an emerging process, competitors often follow.

Michael Siemer of IMDS has 17 years of product development and AM experience. In 2003, he founded Mydea Technologies, a Kinkos-like AM service bureau later acquired by IMDS. Some of this article is excerpted from the rapid tooling section of Wohlers Report 2012, which he coauthored.

Related Content

4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read More3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More