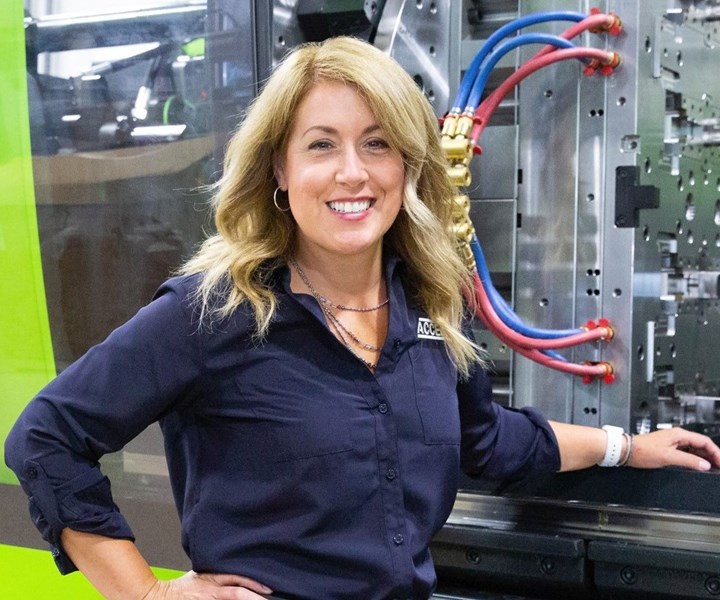

2020-2023 Editorial Advisory Board: Meet New Board Member Camille M. Sackett

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

Camille M. Sackett, vice president of Sales and Project Management for Accede Mold & Tool in Rochester, New York, is one of MMT’s new editorial advisory board members.

Camille Sackett comes to MoldMaking Technology’s Editorial Advisory Board as an engineering, sales, marketing and business development professional. We recognized Camille in May 2017 as part of our series on Women Impacting Moldmaking. She was the director of Business Development & Engineering Support for Accede Mold & Tool in Rochester, New York; as of 2021, she is now the vice president of sales and project management.

In her original position as director of Business Development & Engineering Support, Camille worked on day-to-day sales and client-relationship management, tracking new markets and emerging trends and proposing and developing new strategic partnerships to meet short- and long-term objectives in order to reach business needs and requirements. More specifically, she quoted new projects, meet new and potential customers, managed the website and social media and exhibited at trade shows and conferences.

As an avid life-long learner, she is currently working on a combined Bachelor’s/Master’s of Business Administration in business management degree with the State University of New York Empire State College. She studied manufacturing engineering at Rochester Institute of Technology and Monroe Community College and earned degrees in engineering science and mechanical engineering technology. Camille is also an active member of PLASTICS, SPE and RTMA.

Camille started as an apprentice mold designer at Accede in 1993. She completed a six-year program to become a senior mold designer and program manager. Other roles at Accede have included second-shift engineering manager, ISO/QS lead auditor and QS management rep.

With Camille’s participation in the EAB, we also get the expertise of the Accede team on operations, manufacturing, engineering, quality, mold sampling and facility safety and maintenance.

Established in 1981, Accede is an ISO 9001-certified, ITAR-registered, U.S. mold builder taking on the most demanding mold challenges including high cavitation, stack, in-mold close, unscrewing and multi-shot with a broad mix of two-shot technologies including SpinStack and servo solutions. The shop offers turnkey systems integration, in-house sampling up to 720 tons, inspection, cleanroom, process validation and global customer support. Accede is privately held by the second-generation owner, Roger Fox, with a third-generation workforce.

With Camille’s participation in the EAB, we also get the expertise of the Accede team on operations, manufacturing, engineering, quality, mold sampling and facility safety and maintenance. Meanwhile, she has first-hand experience with design, sales and marketing, quality standards and organizational process development. As a woman in a primarily male-dominated field, she can also speak directly to her personal experiences working in the industry as a minority. Camille hopes to feel more connected to the industry by serving on MMT’s EAB.

She is a mom of three—two sons, 12 and 15, and one 17-year old daughter—and is active in their schools and sports teams/clubs, including baseball, wrestling and competitive cheerleading. Camille is an Audible addict and can’t get enough of audiobooks. Her family will testify that they have the “pleasure” of listening along to her books while she’s doing house chores and/or driving them to their events near or far.

Related Content

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreRead Next

2020-2023 Editorial Advisory Board: Meet New Board Member Davide Masato Ph.D.

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

Read More2020-2023 Editorial Advisory Board: Meet New Board Member Marion Wells

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More