Surface Treatment

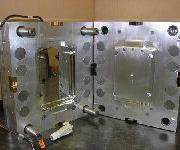

Elite Mold & Engineering: Team Elite

Being both a moldmaker and a molder allows Elite Mold to be a one-stop team for its customers and the MoldMaking Technology 2009 Leadtime Leader Honorable Mention Award: Small Shop.

Read MoreGreater Accuracy and Productivity Via Surface Finishing and Cleaning

Choosing the optimum type of flexible hone or brush can be highly effective in improving the accuracy of mold assembly or enhancing injection molding productivity.

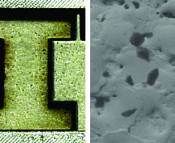

Read MorePolishing Process: Micro Machining Process

MMP, which stands for micro machining process, is a proprietary superfinishing method for metallic parts that delivers consistent, repeatable results using a finely controlled automated process.

Read MoreElectrode Effect on a Quality EDM Finish

The production of fine surface finishes in the cavity does not come with the technological improvements of the EDM sinker unless an electrode material of higher quality is used.

Read MoreDirect Metal Laser Sintering vs. Conventional Tool, Part Two

In this head-to-head comparison, conventional toolmaking seemed to be the superior route to go from a cost, quality and leadtime perspective.

Read MoreNanotechnology Benefits to the Mold

Nano-formulated mold coatings can address the part fill and release challenges that come with highly complicated design requirements, expedited manufacturing expectations and high raw material prices for molds and resins.

Read MoreIs It Still Time to Reach for a Die Profiler?

Pointers for bringing a polished surface to a high mirror finish. You have finished machining your mold core and cavity and removed them from your CNC machine. The mold components are machined in tough H-13 steel and contain several deep grooves and slots that must be properly polished to allow the molded part to eject. What is the best method for bringing the polished surface to a high mirror finish?

Read MoreTool Steel and Heat Treatment, Part 2

Tool steel, its classification, heat treatment and how to consider manufacturing methods in relation to heat treatment and the metallurgy of heat treatment.

Read MoreMoldmaker Uses a Solution-Based Approach To Mold Flow Analysis

MoldFlow consulting firm assists mold shop as it approached a complex molding program for its customer, Cessna Aircraft Company.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)