Surface Treatment

How to Choose the Right Plated Coatings for Improved Mold Performance

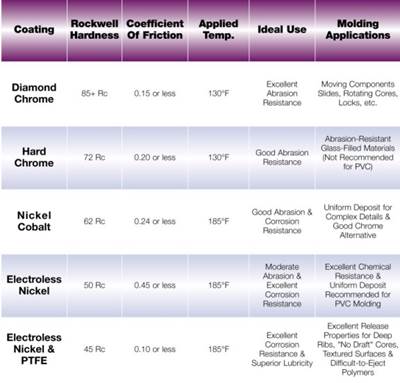

With a basic knowledge of plating types, moldmakers can make an educated coating choice that will improve mold performance.

Read MoreMinnesota Mold & Engineering Group: Strength In Numbers

Four companies unite-serving as a one-stop powerhouse for art to part and anything in-between.

Read MoreTough Coatings Control and Extend Mold Life

Moldmakers can solve tough productivity problems by applying next-generation coatings.

Read MoreHow to Use Indexable Tooling to Optimize Finishing Operations

High-quality indexable insert end milling systems offer moldmakers considerable cost-advantages for many finishing operations.

Read MoreHow to Choose the Right Plated Coating for Improved Mold Performance

There are more than eight different plated coatings for molds - knowing the right one for your application is essential to improving mold life.

Read MoreLaying It on Thick With Specialized Coatings

Phygen coatings offer low friction, high hardness and exceptional wear resistance to extend tool life.

Read MoreGalvanic Corrosion: Prevention Equals Preservation

By educating yourself on some of the common causes of galvanic corrosion, you may save yourself from costly mold repair and rework in the future.

Read MoreBulked-Up Coatings Increase Mold Productivity

Which choice is the best coating - one that provides long production life and minimal maintenance needs.

Read MoreLaser Weld Repair of Molds

A nuclear weapons welding process is used to repair molds for the plastic injection mold industry.

Read MoreEnsuring Mold Steel Polishability

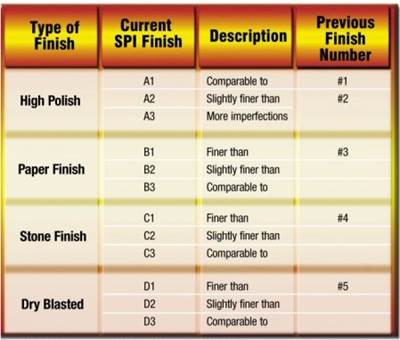

When working on a project that requires high-quality texturing or surface finish, using an electro-slag quality material may be the best option for mold steel.

Read More

.jpg;maxWidth=300;quality=90)