Surface Treatment

Heat Treating of Aluminum Molds

No. 883 is a 1000°F electric universal oven from Grieve, currently used for solution heat treating of aluminum molds at a customer’s facility.

Read MoreGF AgieCharmilles Announces Technology Days 2011

GF AgieCharmilles has announced that it will be holding Technology Days 2011 on June 29 – 30 at its North American headquarters in Lincolnshire, Illinois. The two-day event will include educational seminars and training sessions, as well as technology demonstrations.

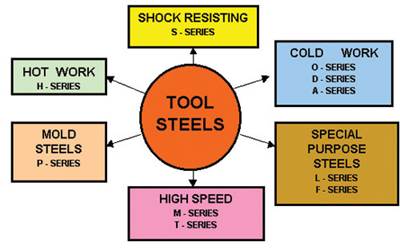

Read MoreVacuum Heat Treating of Tool Steels

Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools, however, special attention needs to be paid during their heat treatment so as to achieve the best properties for a given application.

Read MoreIncrease Mold Protection, Decrease Cycle Times

How to achieve optimal cycle times with the right plating option and the role of early involvement between molder/OEM.

Read MoreSpecialty Flex-Hones for Blending Chamfered Through Holes

Line of specialty Flex-Hones designed to blend and radius sharp edges and remove microburrs on chamfered holes.

Read MoreBest Practices for Surface Finishing

In moldmaking, the surface of the mold has a direct impact on the surface of the product being molded. Because of this, proper surface finishing is essential to producing quality parts.

Read MoreLaser Ablation for Surface Texturing

How moldmakers can improve the level of control exerted in surface texturing.

Read MoreTexturing Molds for Thermoplastics: Factors for Success

Factors to consider when selecting a texture or grain for a thermoplastic mold or die.

Read MoreSilicones Enhance Mold Design, Improve Performance

Silicones have been developed that provide primer-less adhesion to a variety of thermoplastic resins and are optimal for multi-component silicone-to-plastic molding.

Read MoreEvaluating Mold Quality

Quality is the name of the game in manufacturing. It’s not just about quality products, it’s about quality processes—from receiving to shipping, TQM, QA, quality service and delivery. Every facet of the manufacturing process has been assigned standards and how well those standards are met is an indication of the quality of that particular product, process or service. Quality products require quality materials, processes, equipment and tooling—specifically in the case of injection molded parts, quality molds.

Read More

.jpg;maxWidth=300;quality=90)